Ultrahigh-carbon bearing steel material for high-speed precision bearing as well as preparation method and application of ultrahigh-carbon bearing steel material

A precision bearing, ultra-high carbon technology, applied in bearing components, shafts and bearings, mechanical equipment and other directions, can solve problems such as poor high-speed performance of bearings, deformation of parts, and temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The method of preparing ultrahigh carbon bearing steel material for a high-speed precision bearings embodiment of the present invention, comprising the steps of:

[0044] Elements according to a predetermined ratio to prepare a steel billet by continuous casting or molding, rolled into the required specifications, the rolling temperature at 1200 ~ 900 ℃.

[0045] After different rolling of ultra-high carbon bearing steel spheroidizing annealing treatment, the annealing process is heated and incubated 6-15 hr 750 ~ 850 ℃, furnace cooling to 500 ~ 700 ℃ baked.

[0046] The ultra-high carbon bearing steel is spheroidized after quenching heat treatment, quenching temperature is 840 ~ 860 ℃, heating parameters is 1.0 ~ 2.0min / mm, an oil quenching medium or special green quenching medium. After quenching the specimen was 160 ~ 300 ℃ tempering, tempering time 1 to 3 hours.

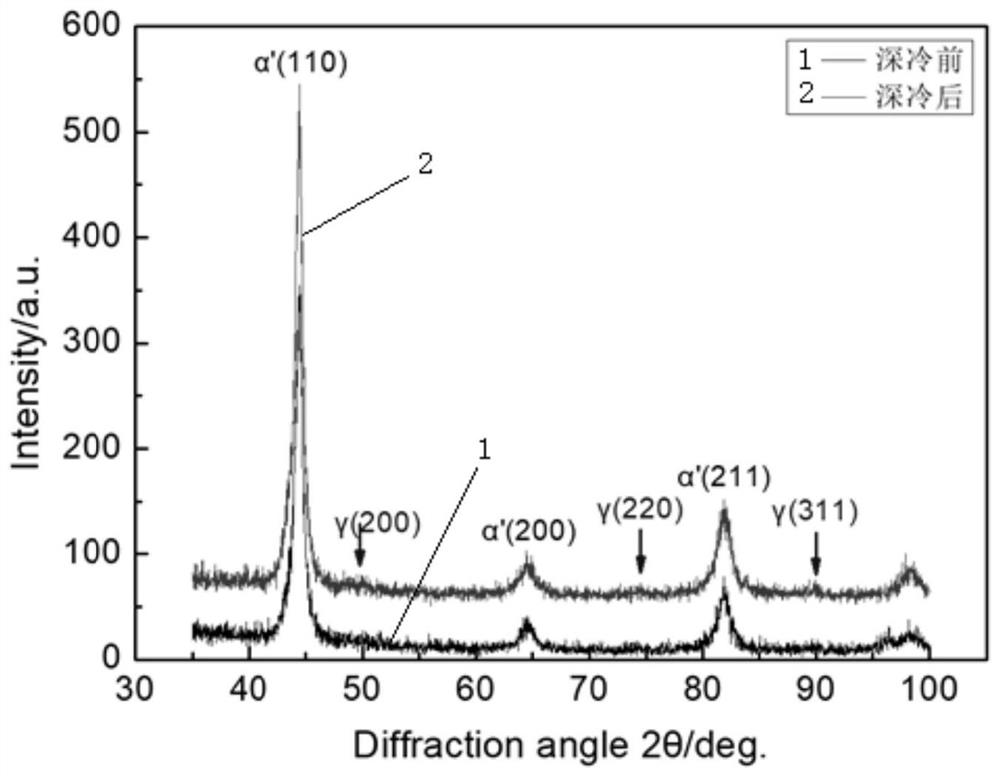

[0047] Such tissue by the treatment process tempered martensite + retained austenite and undissolved carb...

Embodiment 1

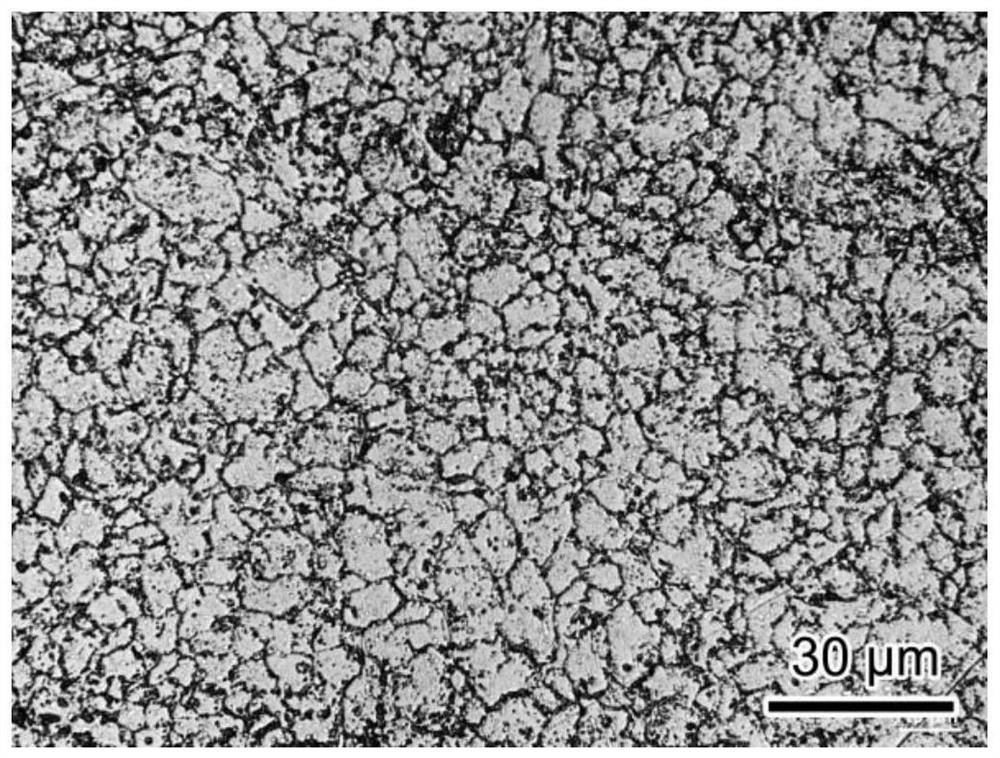

[0059] After Example 1, high carbon bearing steel after quenching and tempering and spheroidization annealing process component 1 embodiment, an electrochemical etching method prior austenite grains, see the results in FIG. figure 1 The average grain size of about 6 m in this state, part of ultrafine grain steel, in addition to a relatively uniform grain size.

Embodiment 2

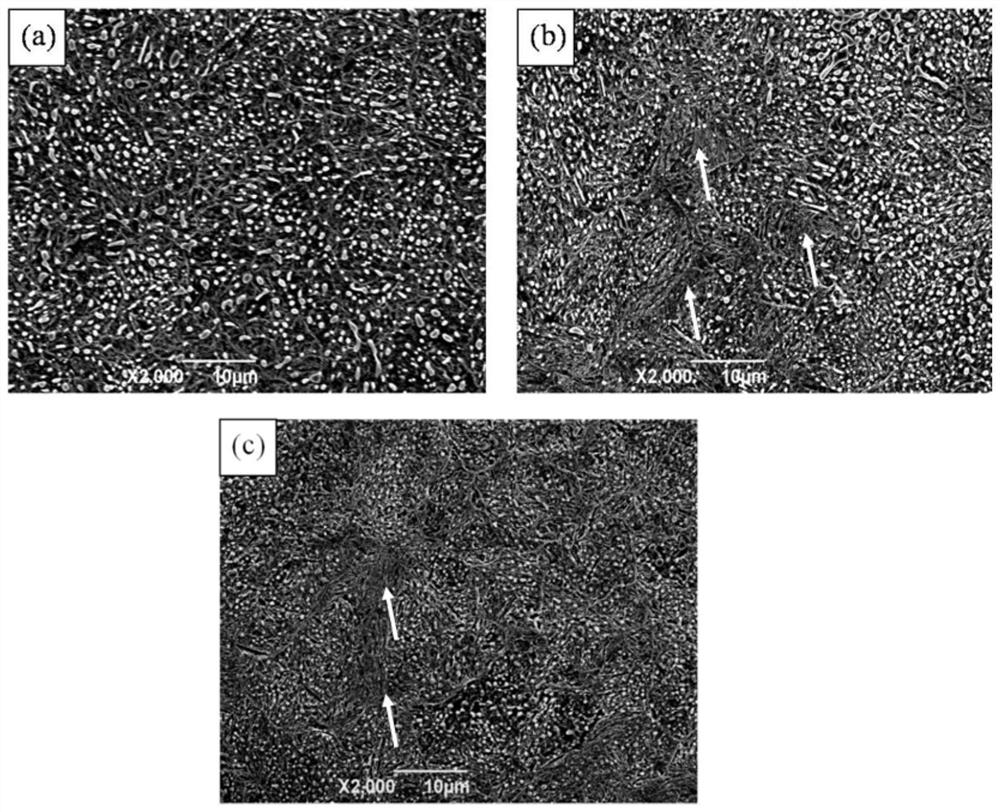

[0060] Tissue ultrahigh carbon bearing steel after quenching and tempering 2, Example 2 as component figure 2 (A), the tissue in this state is excess carbon martensite, residual austenite, carbide particulate is distributed in the martensite matrix, residual austenite can not distinguish at this magnification. figure 2 (A) FIG ultra high carbon bearing steel, figure 2 (B) is FIG GCr15 steel, figure 2 (C) FIG steel is SKF-3. Slightly larger than the carbide particles in the ultra-high carbon bearing steel SKF-3 and GCr15 steel, but is more evenly distributed, although the size of the carbide particles GCr15 steel SKF-3 and smaller, but they are not evenly distributed, carbide sparse region, as shown in arrows. This is because too small carbides readily dissolves when the secondary quenching, this causes uneven distribution of carbide, carbide hardness sparse area will be reduced, this will lead to increased noise during the operation of the bearings, bearing stand ultrahigh Carbon ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com