Ultraviolet radiation resistant concrete and preparation method thereof

A concrete and anti-ultraviolet technology, which is applied in the field of building materials, can solve problems such as the failure of the protective effect of the reinforced concrete protective layer, the deterioration of concrete carbonation, and the impact of concrete stiffness, etc., to achieve the effects of inhibiting migration, strengthening surface strength, and reducing processing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

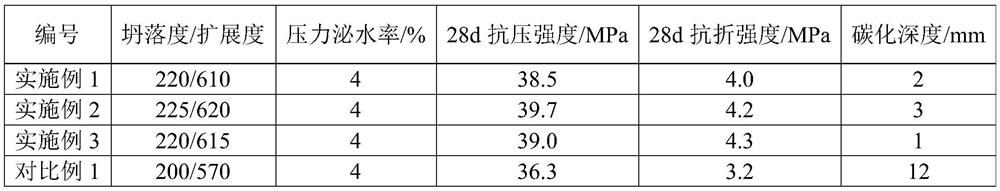

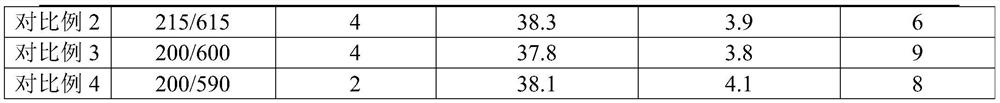

Embodiment 1

[0038] A kind of anti-ultraviolet radiation concrete, its preparation method comprises the steps:

[0039] 1) Weigh each raw material according to the proportion, and each raw material and its proportion by weight include: 280 parts of cement, 100 parts of modified high-titanium heavy slag powder, 10 parts of silica fume, 1030 parts of gravel, high-titanium heavy slag sand G1 950 parts, 6.8 parts of admixture, 2 parts of water-based polyurethane emulsion, 180 parts of water; see Table 2 for specific formula requirements;

[0040] 2) Mix 90 parts of mixing water and 1 part of water-based polyurethane emulsion with gravel and silica fume for 20 seconds, then add cement, modified high-titanium heavy slag powder, high-titanium heavy slag sand and admixtures for mixing 45s, and finally mixed with the remaining mixing water and water-based polyurethane emulsion and stirred for 35s. By controlling the last two feeding conditions and stirring time, the pressure bleeding rate of the ob...

Embodiment 2

[0042] A kind of anti-ultraviolet radiation concrete, its preparation method comprises the steps:

[0043]1) Weigh each raw material according to the proportion, and each raw material and its proportion by weight include: 280 parts of cement, 100 parts of modified high-titanium heavy slag powder, 10 parts of silica fume, 1030 parts of gravel, high-titanium heavy slag sand G2 950 parts, 6.8 parts of admixture, 3.5 parts of water-based polyurethane emulsion, 180 parts of water; see Table 2 for specific formula requirements;

[0044] 2) Mix 90 parts of mixing water and 1.75 parts of water-based polyurethane emulsion with gravel and silica fume for 20 seconds, then add cement, modified high-titanium heavy slag powder, high-titanium heavy slag sand and admixture and mix for 45 seconds. Finally, add the remaining mixing water and water-based polyurethane emulsion and stir for 45s. By controlling the last two feeding conditions and stirring time, the pressure bleeding rate of the res...

Embodiment 3

[0046] A kind of anti-ultraviolet radiation concrete, its preparation method comprises the steps:

[0047] 1) Weigh each raw material according to the proportion, and each raw material and its proportion by weight include: 280 parts of cement, 100 parts of modified high-titanium heavy slag powder, 10 parts of silica fume, 1030 parts of gravel, high-titanium heavy slag sand G3 950 parts, 6.8 parts of admixture, 5 parts of water-based polyurethane emulsion, 180 parts of water; see Table 2 for specific formula requirements;

[0048] 2) Mix 90 parts of mixing water and 2.5 parts of water-based polyurethane emulsion with gravel and silica fume for 20 seconds, then add cement, modified high-titanium heavy slag powder, high-titanium heavy slag sand and admixture and mix for 45 seconds. Finally, add the remaining mixing water and water-based polyurethane emulsion and stir for 40s. By controlling the last two additions and stirring time, adjust the pressure bleeding rate of the resulti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com