Efficient flowing type traditional Chinese medicine grinding device

A grinding device and flow-type technology, applied in cleaning methods and utensils, grain processing, cleaning hollow objects, etc., can solve the problems of incomplete grinding, low grinding efficiency, inconvenient movement and blockage, etc., and achieve convenient grinding processing and high grinding efficiency , Strong scraping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

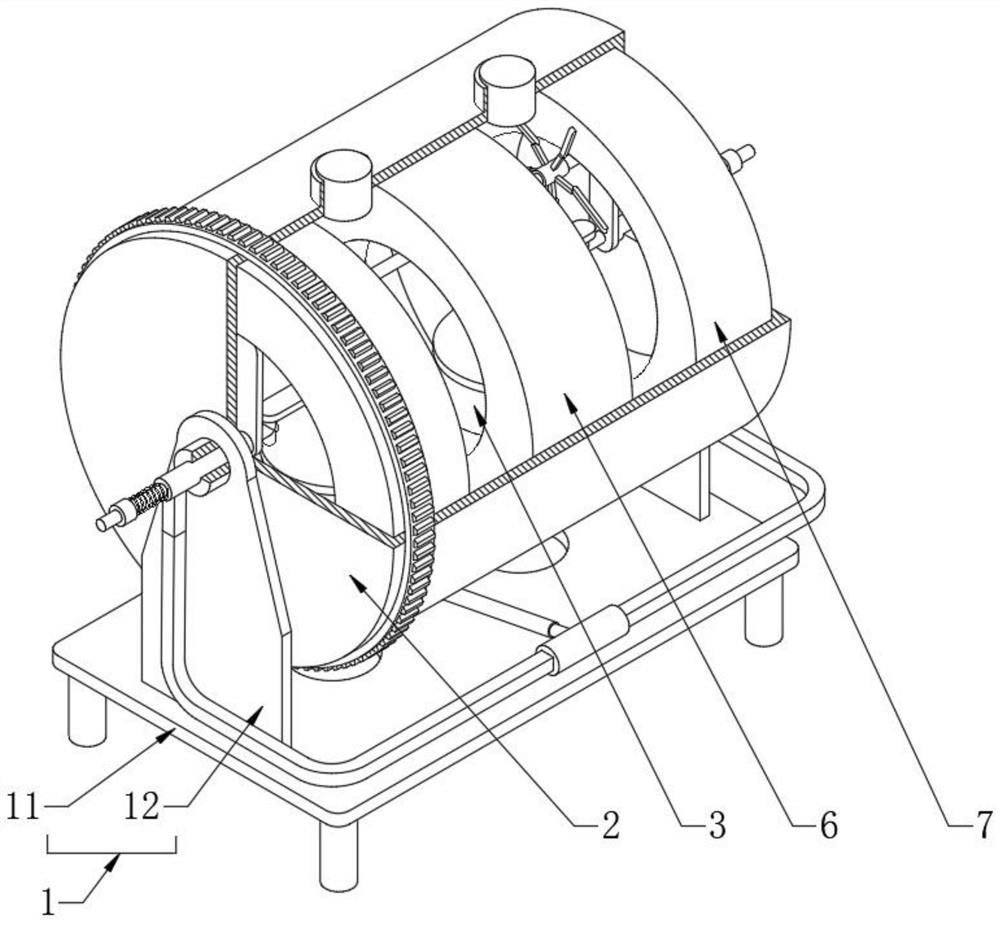

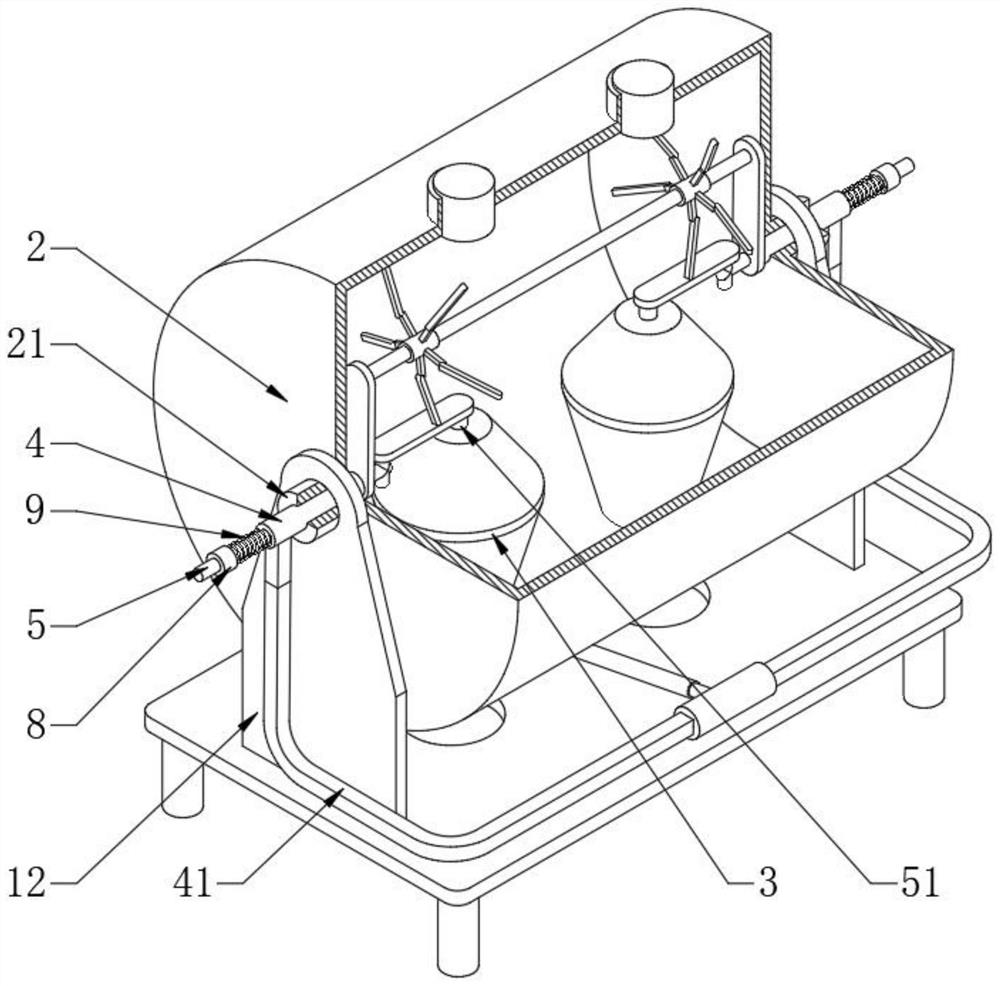

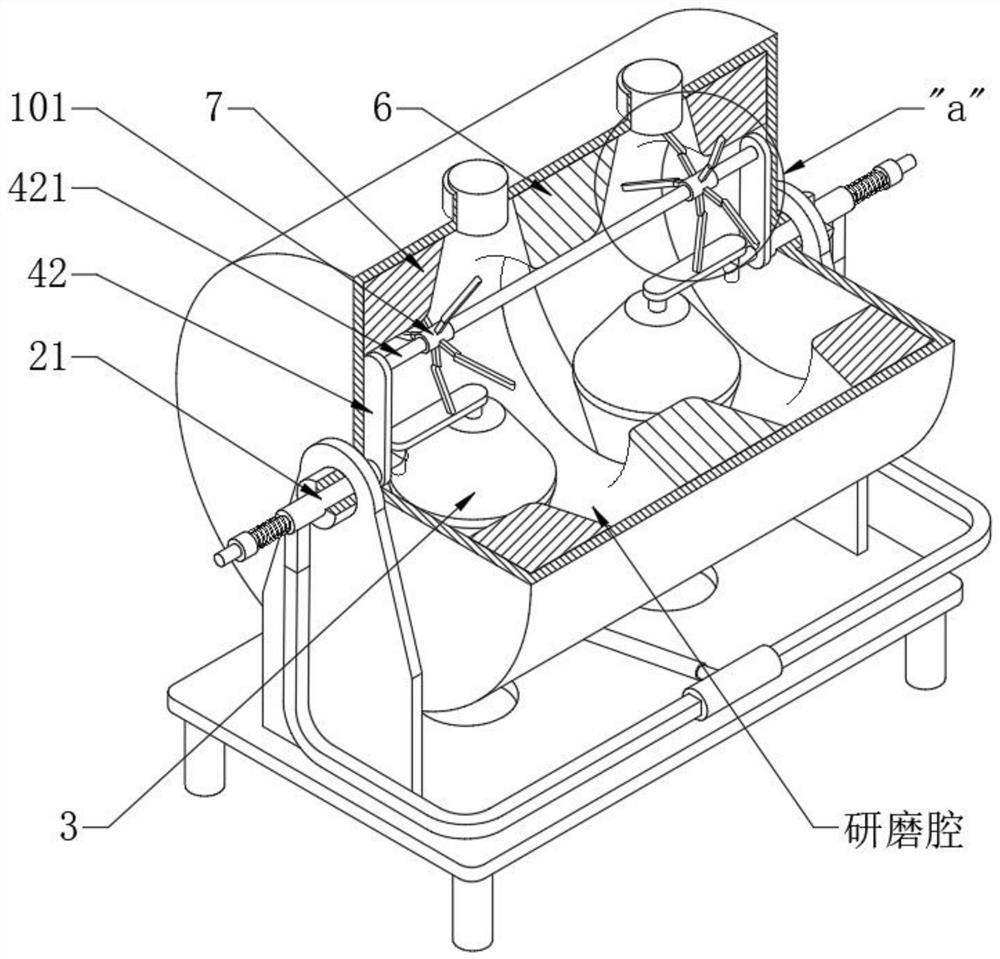

[0032] see Figure 1-3, a high-efficiency flow type traditional Chinese medicine grinding device, including a support frame 1, a grinding outer cylinder 2 and a grinding head 3, the grinding head 3 is in a low-quality state, that is, light in weight, and the grinding outer cylinder 2 is horizontally distributed and its two ends are fixed It is connected with the custodial 21 set coaxially, the rotatable inside of the custodian 21 is provided with a positioning tube 4, and the positioning tube 4 is provided with a guide shaft 5, the guide shaft 5 and the positioning tube 4 are axially elastic sliding fit and are located in the grinding One end inside the outer cylinder 2 is fixedly connected with a positioning shaft 51, wherein an adjusting bolt 8 is screwed on the end of the guiding shaft 5 located outside the grinding outer cylinder 2, and the guiding shaft 5 is sleeved with a screw located between the adjusting bolt 8 and the positioning tube 4. Between the spring 9, the gui...

Embodiment 2

[0034] see image 3 and Figure 4 The difference from Example 1 is that the axis of the anti-blocking shaft 421 is parallel to the axis of the grinding outer cylinder 2, and the anti-blocking shaft 421 is provided with a cleaning brush 101 used in conjunction with the side of the annular powdering plate 7, and the cleaning brush 101 can Scrape off the powdered deposits on one side of the ring-shaped pulverizing plate 7 to eliminate the influence of the powdered deposits on the incomplete grinding of traditional Chinese medicines. Specifically, the cleaning brush 101 includes a positioning sleeve 1011 and a scraper 1012, and the positioning sleeve 1011 is set On the anti-blocking shaft 421 and for rotation fit, the outer peripheral wall of the positioning sleeve 1011 is fixedly provided with struts 10111 evenly distributed in the circumferential direction, one side of the scraper 1012 is fixedly connected to the struts 10111 and the other side is connected to the annular powder...

Embodiment 3

[0036] see Figure 5 The difference from Embodiment 1 is that the supporting plate 11 is hinged with an electronically controlled telescopic rod 102, and the action end of the electrically controlled telescopic rod 102 is rotatably connected with the connecting frame 41. Controlling the expansion and contraction of the electronically controlled telescopic rod 102 can control the relative support of the connecting frame 41 The rotation of the plate 12 can change the inclination angle of the grinding head 3, which is suitable for the grinding process at different stages in the traditional Chinese medicine grinding process. When the accumulation is congested, the inclination of the grinding head 3 can be adjusted backwards to increase the rolling space of the traditional Chinese medicine. After the Chinese medicine particles are gradually refined, the grinding head 3 is controlled to be at the bottom position. At this time, the grinding head 3 can achieve high-speed grinding.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com