Evaporative cooling medium self-circulation full-immersion type water electrolysis hydrogen production system and using method

An evaporative cooling and hydrogen production system technology, applied in the field of hydrogen energy, can solve problems such as accidents, high requirements on the surrounding environment, and unsatisfactory heat dissipation effects, and achieve high heat exchange efficiency, high space utilization, and intensive equipment The effect of layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The practice of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation of the invention, only for example. While by way of illustration that the advantages of the invention will become apparent and more readily appreciated.

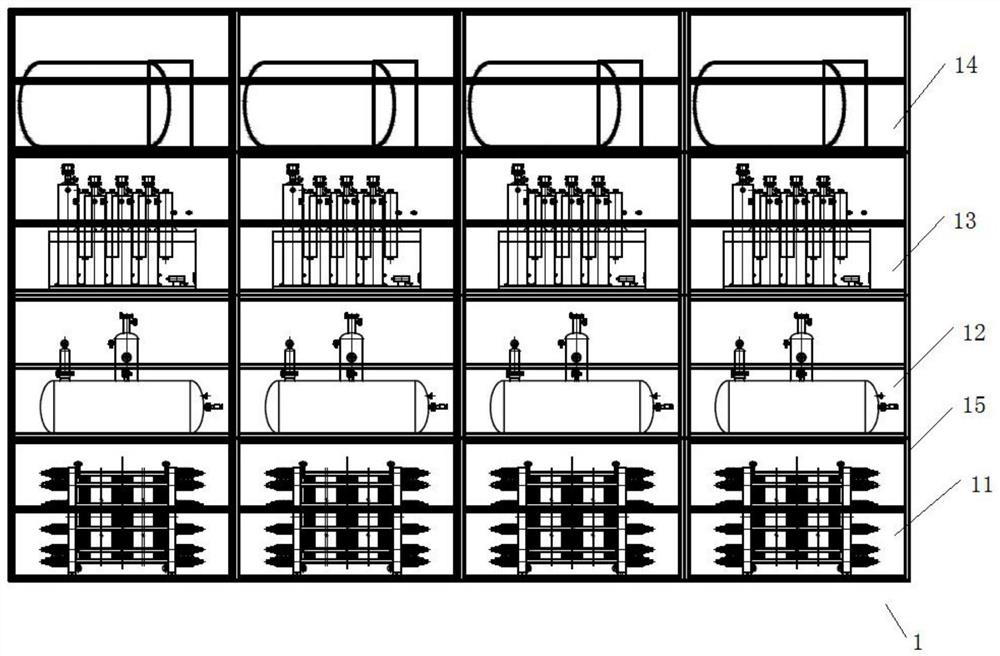

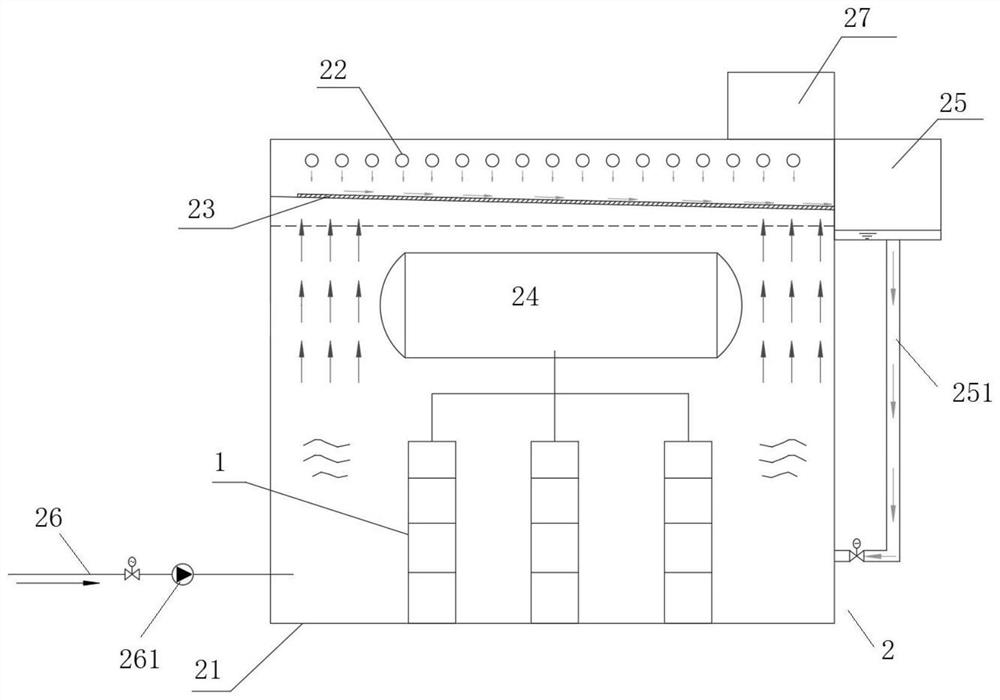

[0031] Referring to the drawings seen: evaporative cooling medium from the circulation total immersion in water electrolysis system comprising: a plurality of sets of vertically hydrogen array unit 1, the complement system evaporative cooling medium 2, each of said vertical array means hydrogen 1 sequentially from bottom to top comprises a plurality of electrolytic cell 11, a plurality of gas-liquid separator 12, the drying device 13 and pressurized with hydrogen purification apparatus 14, plural sets of a vertical array of parallel spaced means hydrogen;

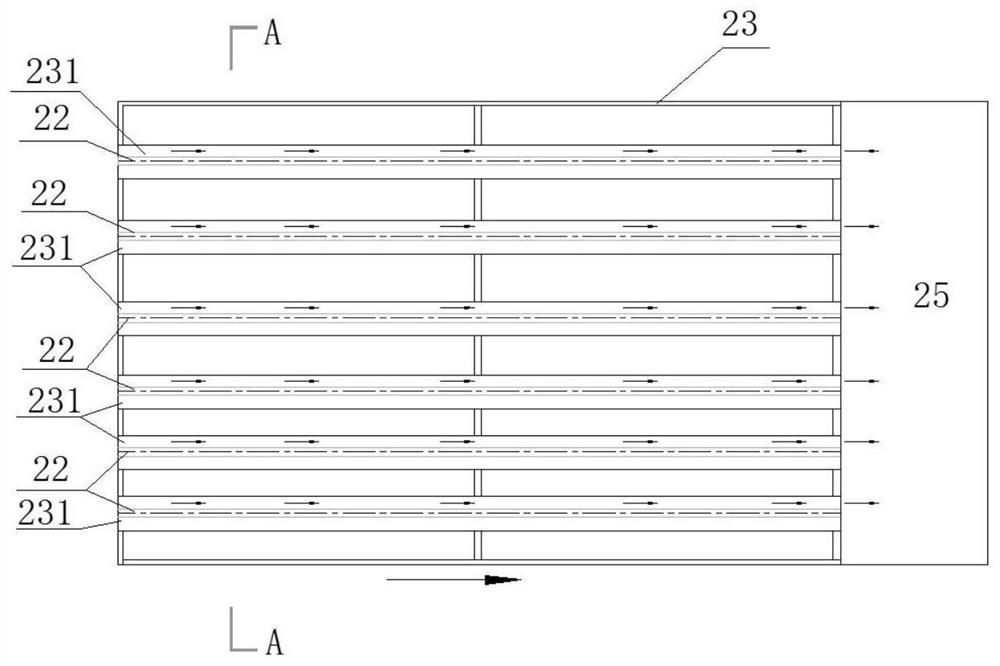

[0032] The complement system evaporative cooling medium 21 enclosed container 2 comprises, at the top of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com