Composite nano-material as well as preparation method and application thereof

A technology of composite nanomaterials and composite agents, applied in nanotechnology, nanotechnology, nanomedicine, etc., can solve the problems of inability to diagnose tumors, difficulty in achieving treatment goals, time-consuming and labor-intensive problems, and achieve excellent imaging performance, good magnetic sensitivity, The effect of excellent biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

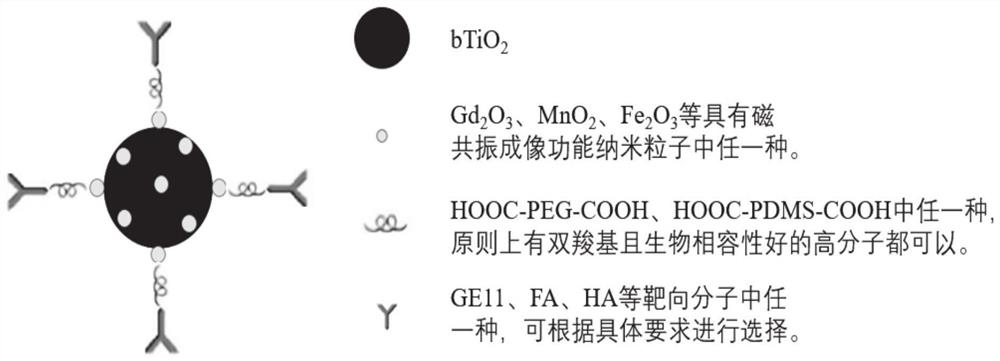

[0124] A method for preparing a diagnosis and treatment integrated gadolinium-titanium composite nanomaterial (i.e. a contrast / photothermal therapy composite agent), said method comprising the following steps:

[0125] a) Preparation of bTiO 2 Nanoparticles;

[0126] b) Preparation of Gd 2 o 3 -bTiO 2 Composite nanomaterials;

[0127] c) Preparation of Gd 2 o 3 -bTiO 2 -PEG composite nanomaterials;

[0128] d) Preparation of Gd 2 o 3 -bTiO 2 - PEG-GE11 composite nanomaterial, that is, a composite agent for contrast / photothermal therapy.

[0129] In this application, step a) prepares bTiO 2 For nanoparticles, use P25 as raw material, NaBH 4 as a strong reducing agent.

[0130] P25 and NaBH in step a) 4 The mass ratio is 4:1-1:1, preferably 2:1-1:1, more preferably 1:1.

[0131] The grinding time of the grinding in step a) is 10-40 min, preferably 20-40 min, more preferably 40 min.

[0132] The protective gas in step a) is nitrogen or argon.

[0133] The calcin...

Embodiment 1

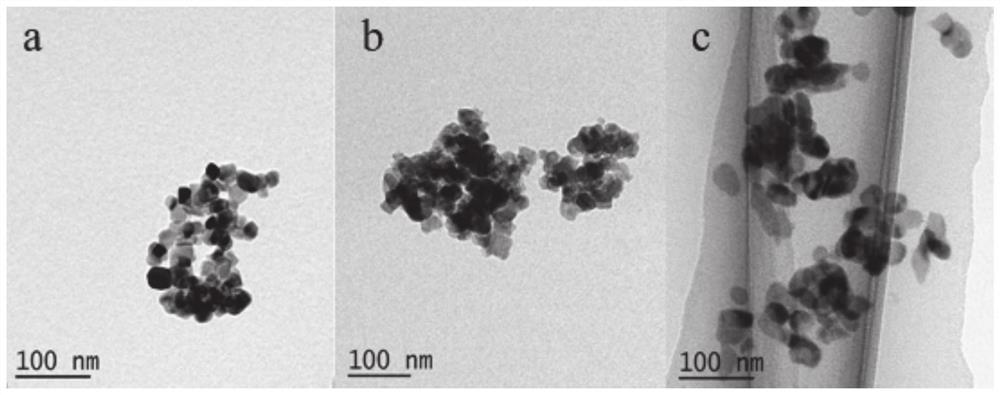

[0173] (1) Weigh 1.5g of P25 solid, NaBH 4 Put 1.5g of the solid in a mortar, grind for 30 minutes, transfer to a porcelain boat, and react in a tube furnace (reaction conditions: react at 350°C for 3h, the heating rate is 10°C / min, and the protective gas is nitrogen) to obtain bTiO 2 . TiO 2 After natural cooling, put it in deionized water overnight to remove unreacted NaBH 4 , followed by centrifugal washing with 2 water and 2 alcohol for 4 times, dried at 70°C and stored in a 4°C refrigerator.

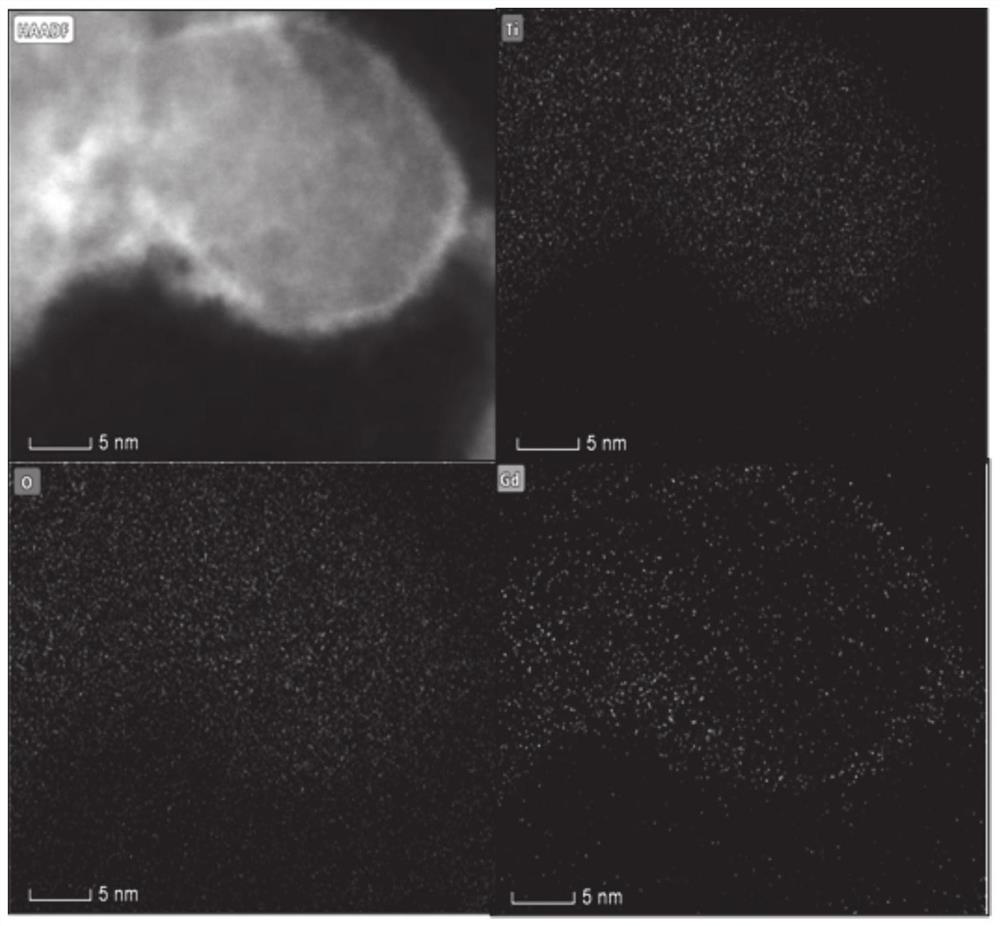

[0174] (2) Weigh 0.906g of solid NaOH and dissolve it in 90.6ml of DEG. After it is completely dissolved, transfer it to a 250ml three-neck flask, then weigh 0.8mmol of gadolinium nitrate hexahydrate and add it to the above alkaline solution; at the same time, weigh bTiO 2 2mmol, dissolved in 20ml DEG, after being dispersed by a cell breaker, added dropwise to the above mixed solution, and finally adjusted to 160ml with DEG, and placed on a magnetic stirrer for reaction (reactio...

Embodiment 2

[0188] (1) Weigh 3.0g of P25 solid, NaBH 4 Put 1.5g of the solid in a mortar, grind for 30 minutes, transfer to a porcelain boat, and react in a tube furnace (reaction conditions: react at 350°C for 3h, the heating rate is 10°C / min, and the protective gas is nitrogen) to obtain bTiO 2 . TiO 2 After natural cooling, put it in deionized water overnight to remove unreacted NaBH 4 , followed by centrifugal washing with 2 water and 2 alcohol for 4 times, dried at 70°C and stored in a 4°C refrigerator.

[0189] (2) Take by weighing 0.906g of solid NaOH and dissolve it in 90.6ml of DEG (diethylene glycol). After dissolving completely, transfer it to a 250ml three-neck flask, then weigh 0.8mmol of gadolinium nitrate hexahydrate and add it to the above-mentioned alkaline solution. Weigh bTiO 2 2mmol, dissolved in 20ml DEG, after being dispersed by a cell breaker, added dropwise to the above mixed solution, and finally adjusted to 160ml with DEG, and placed on a magnetic stirrer fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com