Cooked food film and making process thereof

A production process and cooked food technology, applied in the direction of food ingredients as color, food ingredients as antimicrobial preservation, food science, etc., can solve problems such as dull luster, juice loss, rapid growth of microorganisms, etc., to achieve simple and convenient production process, avoid Effects of rapid growth and improvement of color vision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

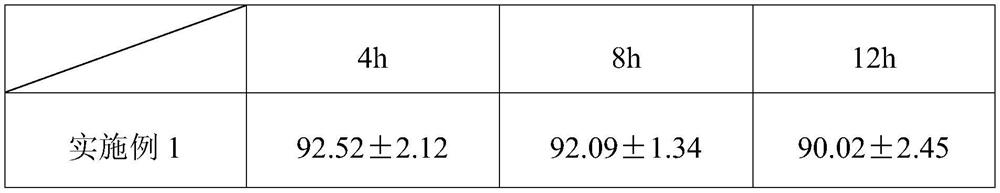

Embodiment 1

[0033] A cooked food film, which is made through the following steps:

[0034]Soup: 1.4g Luo Han Guo, 2.6g cloves, 0.7g tangerine peel, 1.0g ginger, 1.0g fragrant fruit, 1.1g nutmeg, 1.2g star anise, 1.0g grass fruit, 0.5g fragrant leaves, 1.0g amomum, kaempferen 0.7g, Angelica dahurica 0.7g, Baikou 1.0g, Caokou 0.7g, cumin 1.5g, cinnamon 1.5g, Biba 0.8g, red branch 0.3g, dried chili 1.5g, Huadiao wine 20g, Nanrui 30g, straw mushroom 45g of sauce, 5g of dark soy sauce, 20g of light soy sauce, 1.5g of ginger, 30g of carrot, 17g of green onion and 8g of garlic are made into soup according to the recipe;

[0035] Boil the juice: add 3000g of water to the pot, add the soup prepared above after boiling, and boil for 35 minutes;

[0036] Dissolve gelatin: Soak 350g of gelatin in 150g of cold water, absorb water and swell for 1.8 hours, then put it into the reaction kettle together with water, keep the temperature at 63°C, and keep stirring until there are no lumps of gel particles,...

Embodiment 2

[0039] A cooked food film, which is made through the following steps:

[0040] Soup: 1.8g Luo Han Guo, 2.8g cloves, 1.0g tangerine peel, 1.4g ginger, 1.4g fragrant fruit, 1.4g nutmeg, 1.8g star anise, 1.3g grass fruit, 0.8g fragrant leaves, 1.4g amomum, kaempferen 1.0g, Angelica dahurica 1.0g, Baikou 1.3g, Caokou 1.0g, Fennel 1.8g, Cinnamon bark 1.8g, Biba 1.0g, Red branch 0.6g, Dried chili 1.8g, Huadiao wine 17g, Southern milk juice 28g, Straw mushroom 40g of sauce, 4g of dark soy sauce, 16g of light soy sauce, 1.3g of ginger, 28g of carrot, 17g of green onion and 5g of garlic are made into soup according to the recipe;

[0041] Boil the juice: add 3100g of water to the pot, add the soup prepared above after boiling, and boil for 40 minutes;

[0042] Dissolving gelatin: Soak 355g of gelatin in 160g of cold water, absorb water and swell for 1.4h, then put it into the reaction kettle together with water, keep the temperature at 65°C, and keep stirring until there are no lumps ...

Embodiment 3

[0045] A cooked food film, which is made through the following steps:

[0046] Soup: 1.1g Luo Han Guo, 2.2g cloves, 0.5g tangerine peel, 0.9g ginger, 0.7g fragrant fruit, 0.9g nutmeg, 1.1g star anise, 0.9g grass fruit, 0.4g fragrant leaves, 0.6g amomum, kaempferen 0.6g, Angelica dahurica 0.5g, Baikou 0.7g, Caokou 0.5g, cumin 1.1g, cinnamon 1.2g, Biba 0.5g, red branch 0.2g, dried chili 1.3g, Huadiao wine 23g, Nanrui 33g, straw mushroom 47g of sauce, 7g of dark soy sauce, 25g of light soy sauce, 1.8g of ginger, 33g of carrot, 20g of green onion and 10g of garlic are made into soup according to the recipe;

[0047] Boil the juice: add 2800g of water to the pot, add the soup prepared above after boiling, and simmer for 30 minutes;

[0048] Dissolving gelatin: Soak 345g of gelatin in 155g of cold water, absorb water and swell for 1.2h, then put it into the reaction kettle together with water, keep the temperature at 60°C, and keep stirring until there are no lumps of gel particles...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com