Method for testing chlorine resistance of automobile part made of polyamide material

A technology of auto parts and test methods, which is applied in the direction of analysis materials, weather resistance/light resistance/corrosion resistance, measuring devices, etc. There are no problems such as quantitative evaluation of polyamide material properties, and the effects of subjective evaluation results, improved experimental accuracy, and reduced experimental operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

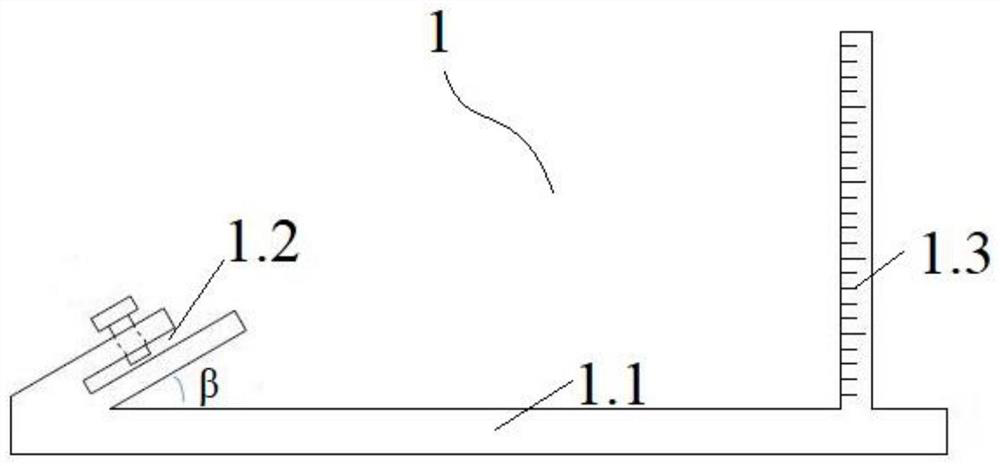

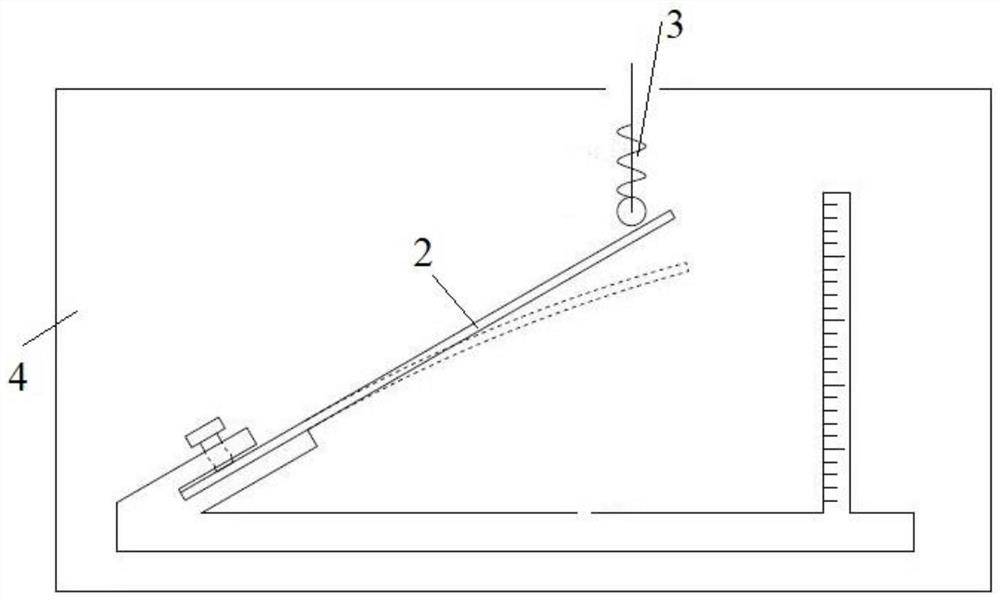

[0053] This embodiment discloses a test method for the chlorine resistance performance of a lower guard plate part of an automobile chassis, wherein the raw material components of the part include PA6 with a molecular weight of 20,000-30,000. The specific test steps are as follows:

[0054] 1) Cut 5 rulers as 120×20×3mm splines perpendicular to the injection flow direction of the parts, mark points A and B, and place them in a drying dish at room temperature for later use.

[0055] 2) Prepare a calcium chloride solution with a mass concentration of 5% and introduce it into the salt spray tank of the salt spray box.

[0056] 3) Take out a spline from the drying dish, fix it with a clamp, record the scale value corresponding to the level of point B at this moment, and then put the clamp device into the salt spray box.

[0057] 4) Select the 10N load pulse indenter, and adjust the pulse indenter to be directly above point A of the spline and infinitely close.

[0058] 5) Set th...

Embodiment 2

[0066] This embodiment discloses a test method for the chlorine resistance performance of automobile engine cover parts, wherein the raw material components of the parts include PA6 with a molecular weight of 18,000-20,000, modified glass fibers, salt-resistant acrylic copolymer resins, antioxidants, anti-oxidants, etc. Abrasives etc. Among them, PA6 accounts for about 60%, modified glass fiber accounts for 30%, salt-resistant acrylic copolymer resin accounts for 9%, and the rest are additives such as antioxidants and wear-resistant agents. The modified product of zirconium and silane coupling agent, the molecular weight of the salt-resistant acrylic copolymer resin is about 3000.

[0067] The specific test steps are the same as the above-mentioned Example 1; and the specific evaluation grades are shown in the following table.

[0068] Table 3 Evaluation list of chlorine resistance performance of automobile hood parts

[0069]

[0070]

Embodiment 3

[0072] This embodiment discloses a test method for the chlorine resistance performance of an automobile water tank cover part, wherein the raw material components of the part include PA66 with a molecular weight of 20,000-30,000, modified glass fiber, salt-resistant acrylic copolymer resin and antioxidant, anti-oxidant Abrasives etc. Among them, PA66 accounts for about 70%, modified glass fiber accounts for 15%, salt-resistant acrylic copolymer resin accounts for 10%, and the rest are additives such as antioxidants and wear-resistant agents. The modified product of zirconium and silane coupling agent, the molecular weight of the salt-resistant acrylic copolymer resin is about 3000.

[0073] The specific test steps are the same as the above-mentioned Example 1; and the specific evaluation grades are shown in Table 4 below;

[0074] Table 4 Evaluation list of chlorine resistance performance of automobile hood parts

[0075]

[0076]

[0077] From the above-mentioned Exam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com