Cooling water supply device for sliding bearing of vertical motor of deep-well pump and control method of cooling water supply device

A vertical motor and sliding bearing technology, applied in water supply devices, water supply devices, cooling/ventilation devices, etc., can solve the problems of inability to monitor the condition of the water supply pipeline, inability to ensure that the water supply is not affected, and poor cooling water quality, etc. The effect of safe and efficient operation, improving equipment operation rate and reducing failure downtime rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

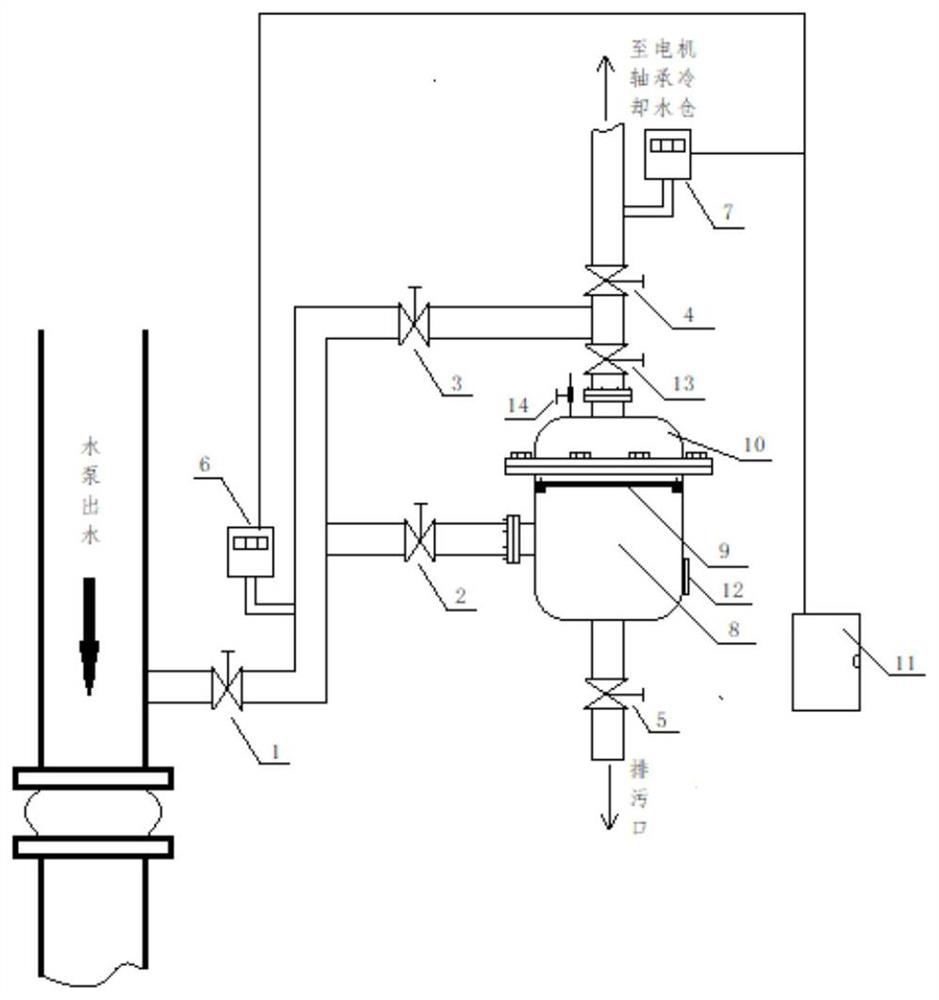

[0042] Embodiment one: the specific implementation plan and steps of the cooling water supply device of a kind of deep well pump vertical motor sliding bearing of the present invention:

[0043] A: From the outlet main pipe of the deep well pump to the opening of the pump control valve (as close as possible to the pump outlet), use DN50 stainless steel welded process pipelines, and install a manual ball valve at a distance of about 300mm from the main pipe, that is, the first valve 1 as the device Install a digital display pressure sensor-6 on the pipeline behind the first valve 1 at about 400mm to monitor the inlet water pressure;

[0044] B: The pipeline installed with the first valve 2 passes through the filter barrel 8 and the filter 9 as the main water supply circuit of the device, and the pipeline installed with the third valve 3 in parallel is used as the backup circuit of the device;

[0045] C: Install the fifth valve 13, the fourth valve 4 and the digital display pre...

Embodiment 2

[0054] Embodiment two: the concrete operation control method of the cooling water water supply device of a kind of deep well pump vertical motor sliding bearing of the present invention:

[0055] Check to confirm that each valve is closed, and the power supply and connection of the digital display pressure sensor, the control box 11 and the monitoring computer of the centralized control center are normal;

[0056] After the motor starts, slowly open the first valve 1 and adjust the pressure value of the digital display pressure sensor 16 to 0.25Mpa; then slowly open the second valve 2 to supply water to the filter bucket 8, and at the same time properly open the exhaust valve 14 to discharge until the air in the barrel is exhausted, the second valve 2 is fully opened, and the exhaust valve 14 is fully closed;

[0057] Then slowly open the fifth valve 13 and the fourth valve 4, and observe the pressure value of the digital display pressure sensor 2 7 at the same time, until the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com