High-performance nodular cast iron spheroidizing agent and manufacturing equipment thereof

A technology of nodular cast iron and nodularizing agent, which is applied in foundry equipment, casting molding equipment, and equipment for transporting casting molds, etc., can solve the problems of low production efficiency, high cost of nodularizing agent, and low degree of automation of processing equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The main component of "spheroidizing agent" is nodularizing elements, such as Mg, Ce, Ca, etc. Spheroidal graphite in ductile cast iron is formed by spheroidizing molten cast iron, making it much stronger than gray cast iron and tougher than malleable cast iron, while maintaining a series of advantages of gray cast iron. However, the "spheroidizer" used in the casting of ductile iron can increase the tendency of the weld to produce "white mouth" and hardened structure, and induce cracks in the weld and heat-affected zone (especially the fusion zone). Therefore, the weldability of ductile iron is worse than that of gray cast iron.

[0039] A high-performance nodularizer for ductile iron, including Si: 35-45 parts, Mg: 7-9 parts, Re: 3-4 parts, Ca: 1-2 parts, Fe: 30-50 parts, Ce: 1- 5 servings.

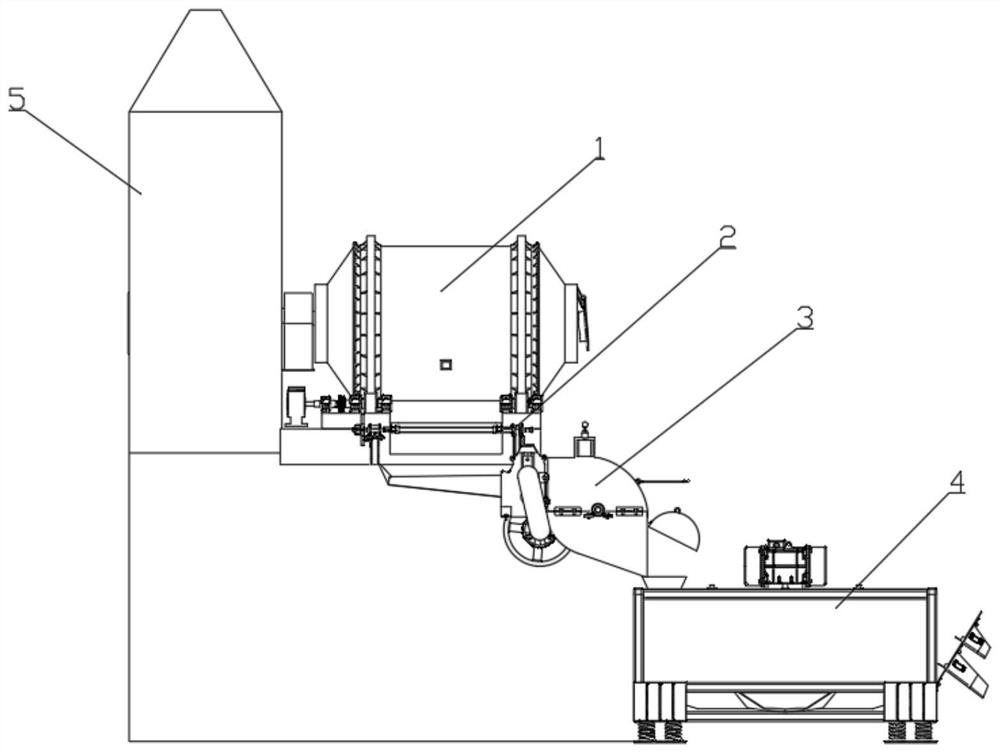

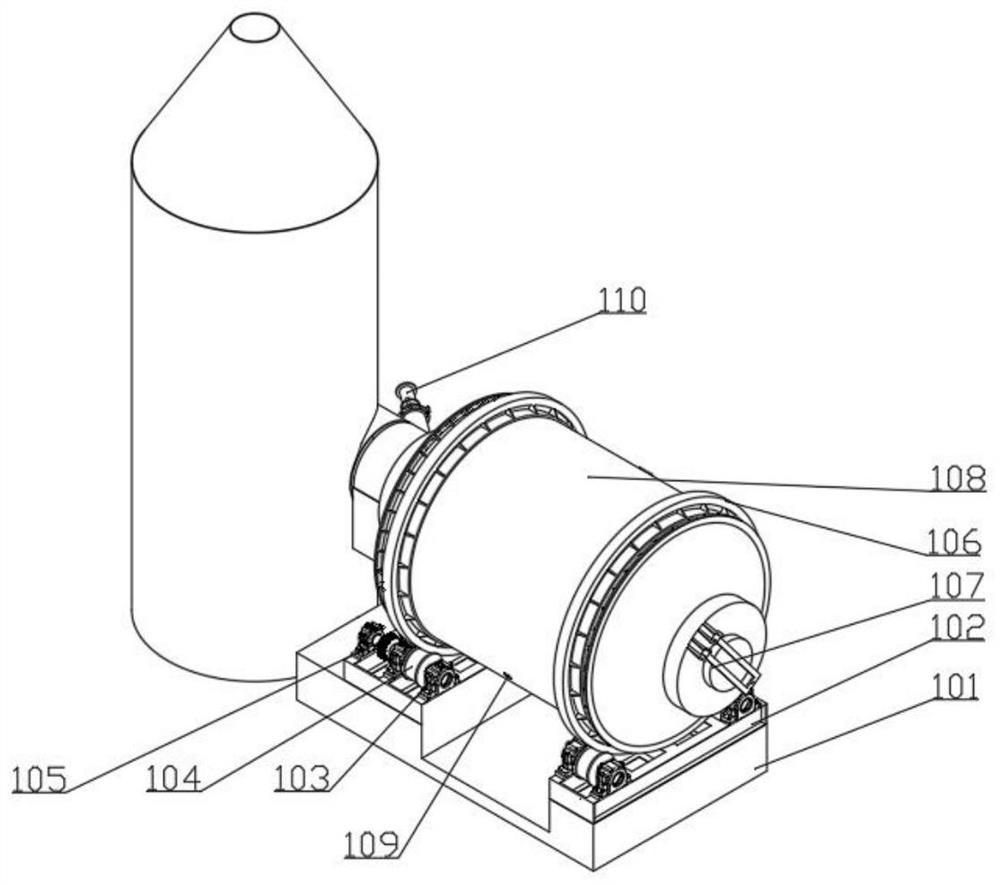

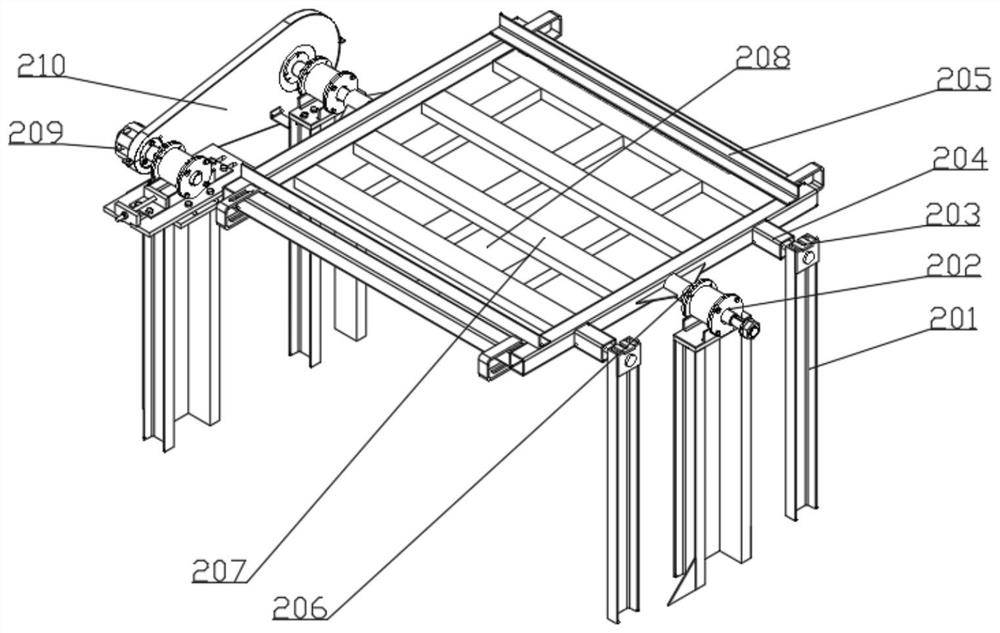

[0040] Such as Figure 1-7 As shown, a high-performance ductile iron nodularizing agent production equipment includes a smelting section 1, a casting section 2, a crushing sec...

Embodiment 2

[0047] The main component of "spheroidizing agent" is nodularizing elements, such as Mg, Ce, Ca, etc. Spheroidal graphite in ductile cast iron is formed by spheroidizing molten cast iron, making it much stronger than gray cast iron and tougher than malleable cast iron, while maintaining a series of advantages of gray cast iron. However, the "spheroidizer" used in the casting of ductile iron can increase the tendency of the weld to produce "white mouth" and hardened structure, and induce cracks in the weld and heat-affected zone (especially the fusion zone). Therefore, the weldability of ductile iron is worse than that of gray cast iron.

[0048] Such as Figure 1-7 As shown, a high-performance nodularizer for ductile iron, including Si: 35-45 parts, Mg: 7-9 parts, Re: 3-4 parts, Ca: 1-2 parts, Fe: 30-50 parts, Ce : 1-5 servings.

[0049] A high-performance ductile iron nodularizing agent production equipment, including a smelting section 1, a casting section 2, a crushing s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com