LTCC substrate material applicable to high frequency and preparation method thereof

A substrate and high-frequency technology, applied in the field of LTCC substrate materials and their preparation, can solve the problems of using in low-frequency occasions, and achieve the effects of wide application range, low dielectric loss and good designability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

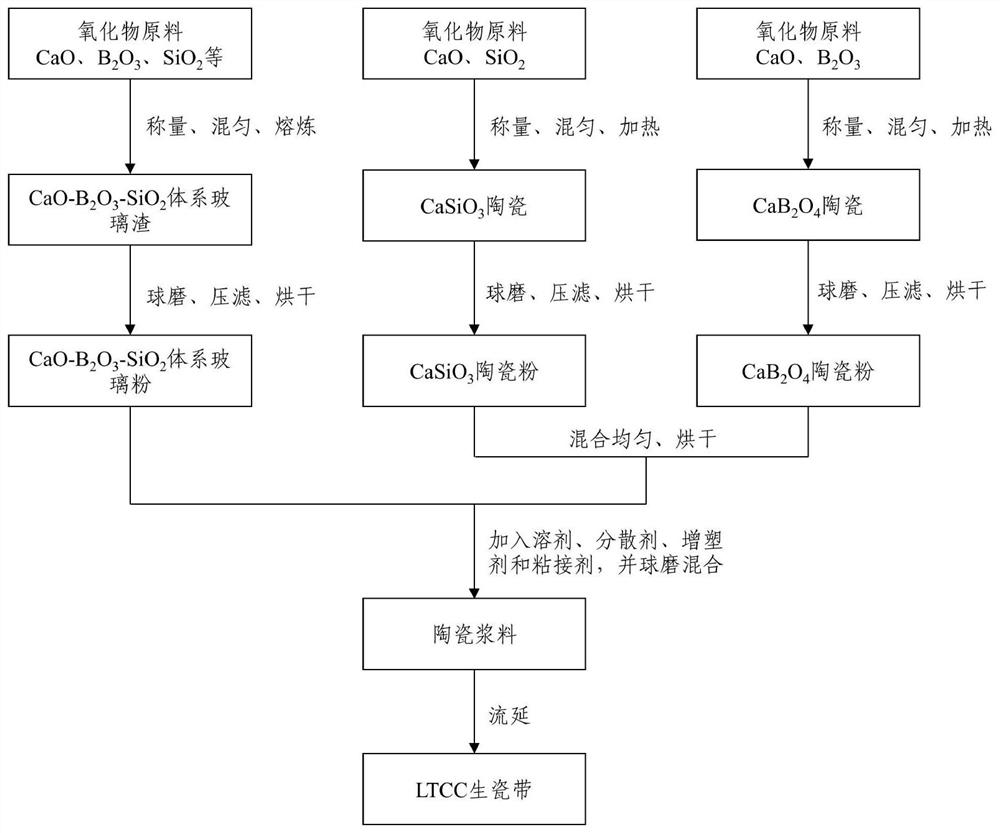

[0034] The present invention also proposes a preparation method suitable for high-frequency LTCC substrate materials, such as figure 1 shown, including the following steps:

[0035] S1: Weigh CaO, B 2 o 3 , SiO 2 , MgO, TiO 2 、Al 2 o 3 and P 2 o 5 , mixed, smelted, and then poured into deionized water to obtain glass slag;

[0036] S2: Weigh CaO and SiO according to the stoichiometric ratio 2 , mixed and heated to synthesize CaSiO 3 ceramics;

[0037] The stoichiometric ratio refers to the ratio of the coefficients in the chemical reaction equation.

[0038] The present invention synthesizes CaSiO by a solid phase reaction method 3 ceramics.

[0039] S3: Weigh CaO and B according to the stoichiometric ratio 2 o 3 , mix well, heat synthesis for the first time, grind the synthesized product into powder again, and then carry out the second heat synthesis to obtain CaB 2 o 4 ceramics;

[0040] The stoichiometric ratio refers to the ratio of the coefficients in t...

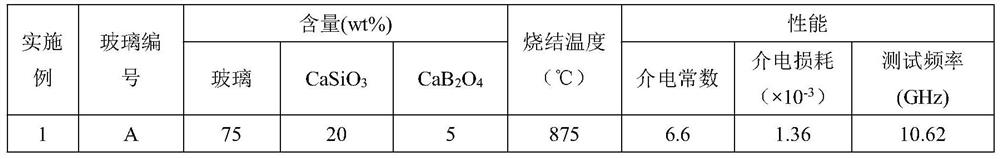

Embodiment 1~12

[0062] This embodiment provides a kind of LTCC substrate material suitable for high frequency, and this LTCC substrate material is made of CaO-B 2 o 3 -SiO 2 System glass-ceramics and mixed ceramics prepared, CaO-B 2 o 3 -SiO 2 See Table 2 for the mass ratio of glass-ceramics and mixed ceramics in the system;

[0063] CaO-B 2 o 3 -SiO 2 System glass ceramics with CaO, B 2 o 3 , SiO 2 , MgO, TiO 2 、Al 2 o 3 and P 2 o 5 Prepared as a raw material, the hybrid ceramic is made of CaSiO 3 Ceramic and CaB 2 o 4 Ceramic mix.

[0064] CaO, B 2 o 3 , SiO 2 , MgO, TiO 2 、Al 2 o 3 and P 2 o 5 The mass ratio of is shown in Table 1;

[0065] CaSiO 3 Ceramic and CaB 2 o 4 The mass ratio of ceramics is shown in Table 2.

[0066] This embodiment also provides a method for preparing the above-mentioned LTCC substrate material suitable for high frequency, including the following steps:

[0067] S1: Weigh CaO and B according to mass ratio 2 o 3 , SiO 2 , MgO, Ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com