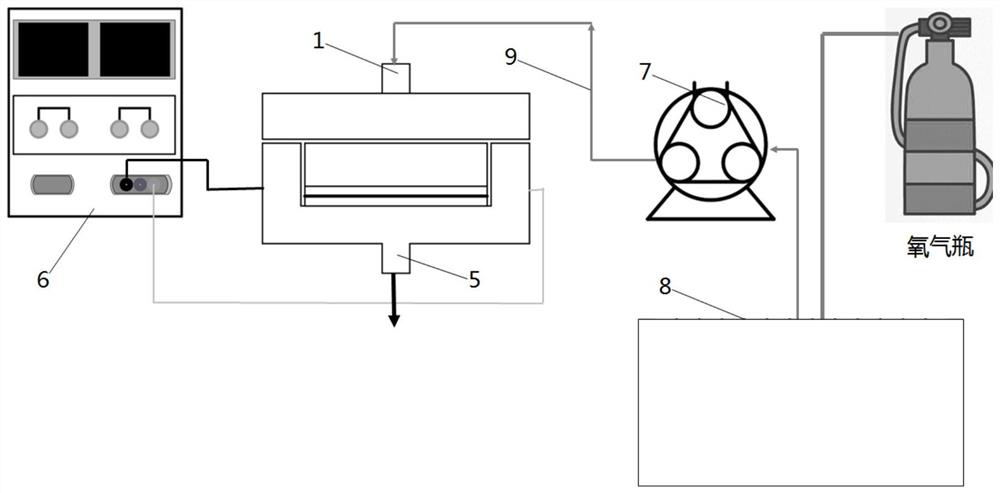

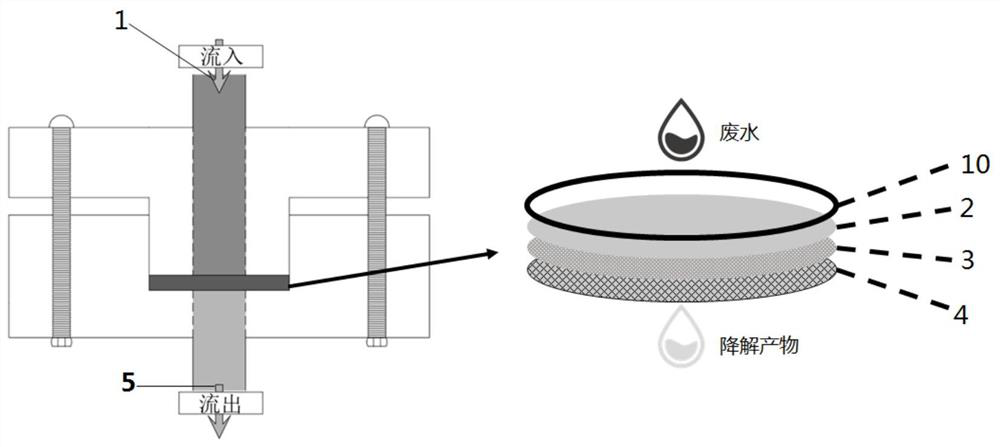

Penetration type heterogeneous electro-Fenton water treatment device and application thereof

A water treatment device and heterogeneous technology, applied in the field of environmental engineering, can solve the problems of limited electric Fenton technology, short contact time, limited catalytic performance, etc., and achieve the effects of facilitating popularization and application, high efficiency and low consumption degradation, and convenient replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

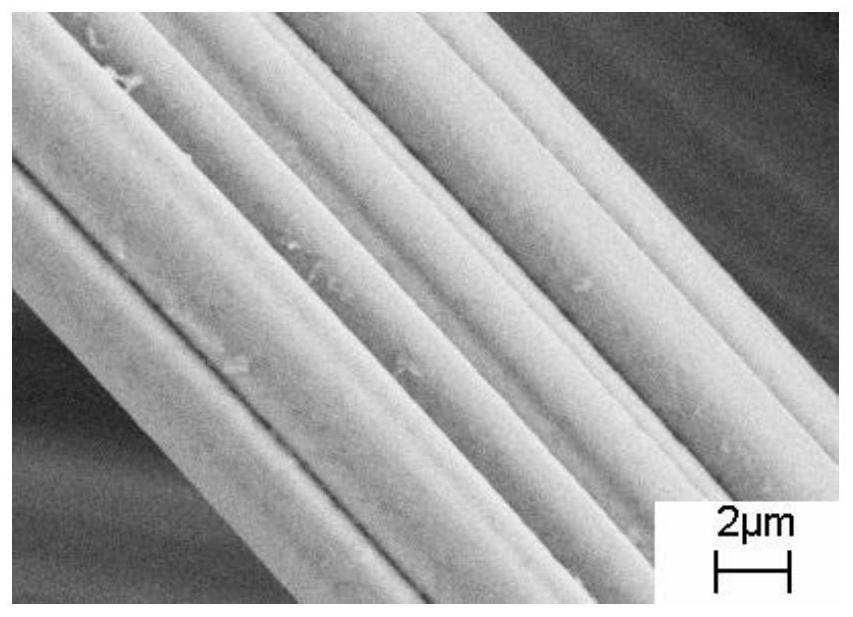

[0041] This embodiment provides a method for preparing a carbon electrode layer loaded with iron nanoparticles, comprising:

[0042] Step 1. Pretreatment of cotton pads: Soak the cotton pads in ethanol solution, ultrasonically treat the ethanol solution soaked with cotton pads, take out the cotton pads after ultrasonic treatment, wash them with deionized water, and dry them to obtain pretreated cotton pads The quality of the ethanol solution is 5 times of the cotton quality, and the mass percentage of ethanol in the ethanol solution is 80%; the ultrasonic frequency of the ethanol solution soaked with cotton is 50kHz, and the ultrasonic power is about 150w. Operate at a duty rate of 60% to 90%, and the ultrasonic treatment time is 20 minutes; the drying temperature is 80°C, and the drying time is 8 hours;

[0043] Step 2, preparation ferrous sulfate solution: 5mg ferrous sulfate is dissolved in 30mL deionized water, obtains ferrous sulfate solution; In described ferrous sulfate...

Embodiment 2

[0056] This embodiment provides a method for preparing a carbon electrode layer loaded with iron nanoparticles, comprising:

[0057] Step 1. Pretreatment of cotton pads: Soak the cotton pads in ethanol solution, ultrasonically treat the ethanol solution soaked with cotton pads, take out the cotton pads after ultrasonic treatment, wash them with deionized water, and dry them to obtain pretreated cotton pads The quality of the ethanol solution is 4 times of the cotton quality, and the mass percentage of ethanol in the ethanol solution is 90%; the ultrasonic frequency of the ethanol solution soaked with cotton is 40kHz, and the ultrasonic power is about 150w. Operate at a duty rate of 60% to 90%, and the ultrasonic treatment time is 15 minutes; the drying temperature is 70°C, and the drying time is 9 hours;

[0058] Step 2, preparation ferrous sulfate solution: 5mg ferrous sulfate is dissolved in 30mL deionized water, obtains ferrous sulfate solution; In described ferrous sulfate...

Embodiment 3

[0068] This embodiment provides a method for preparing a carbon electrode layer loaded with iron nanoparticles, comprising:

[0069] Step 1. Pretreatment of cotton pads: Soak the cotton pads in ethanol solution, ultrasonically treat the ethanol solution soaked with cotton pads, take out the cotton pads after ultrasonic treatment, wash them with deionized water, and dry them to obtain pretreated cotton pads The quality of the ethanol solution is 3 times of the cotton quality, and the mass percentage of ethanol in the ethanol solution is 70%; the ultrasonic frequency for processing the ethanol solution soaked with cotton is 60kHz, and the ultrasonic power is about 150w. Operate at a duty rate of 60% to 90%, and the ultrasonic treatment time is 25 minutes; the drying temperature is 90°C, and the drying time is 7 hours;

[0070] Step 2, preparation of ferrous sulfate solution: 5mg of ferrous sulfate is dissolved in 30mL deionized water to obtain ferrous sulfate solution; in the fe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com