Forced convection device for fin type radiator

A technology of forced convection and radiator, applied in the direction of indirect heat exchangers, heat exchanger shells, tubular elements, etc., can solve the problems of restricted fixed structure and limited effect, so as to improve heat exchange efficiency, increase surface area, and improve heat exchange efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

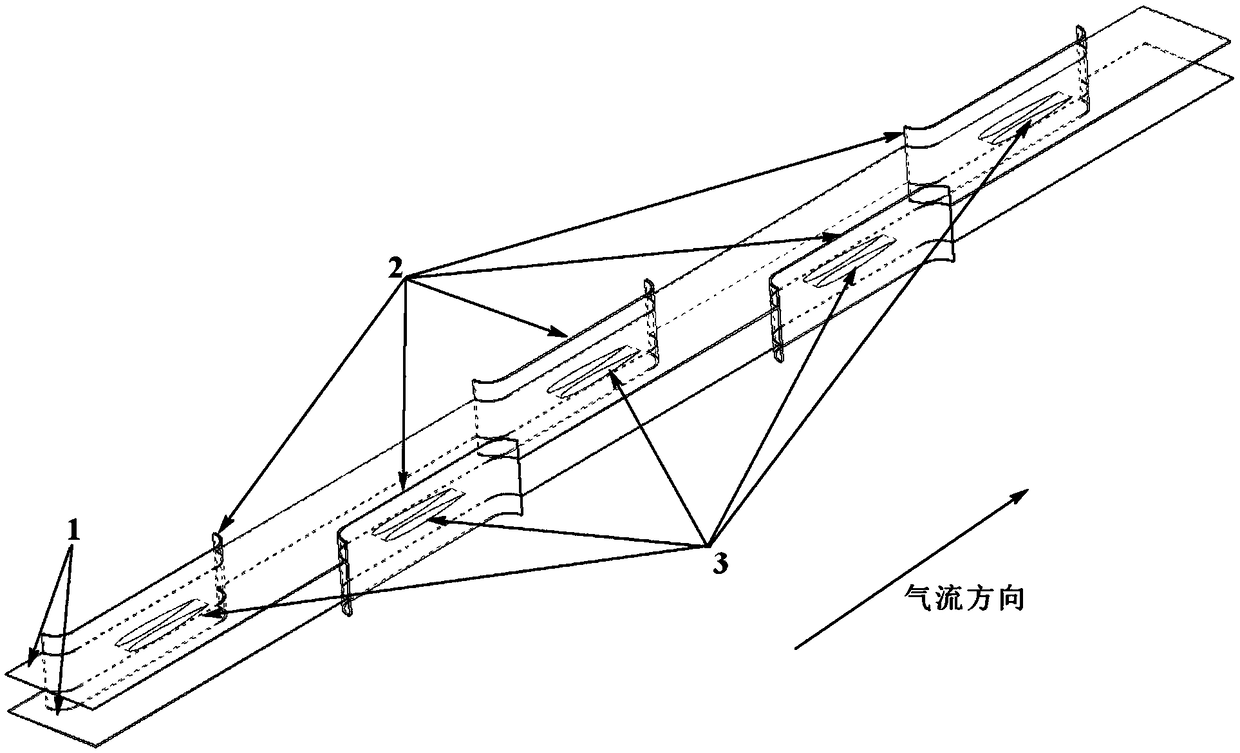

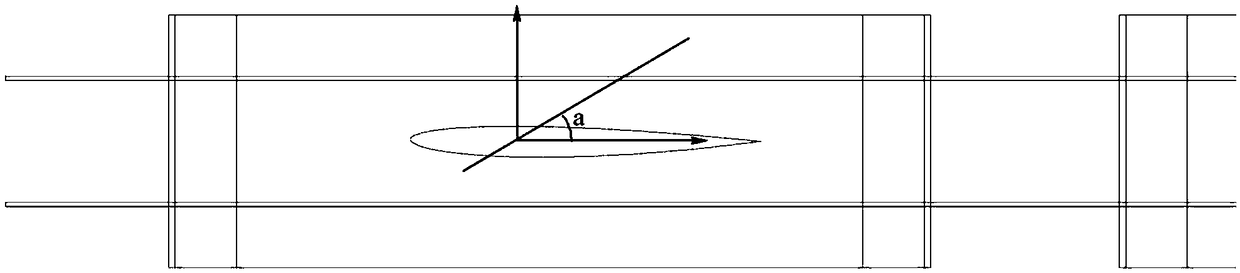

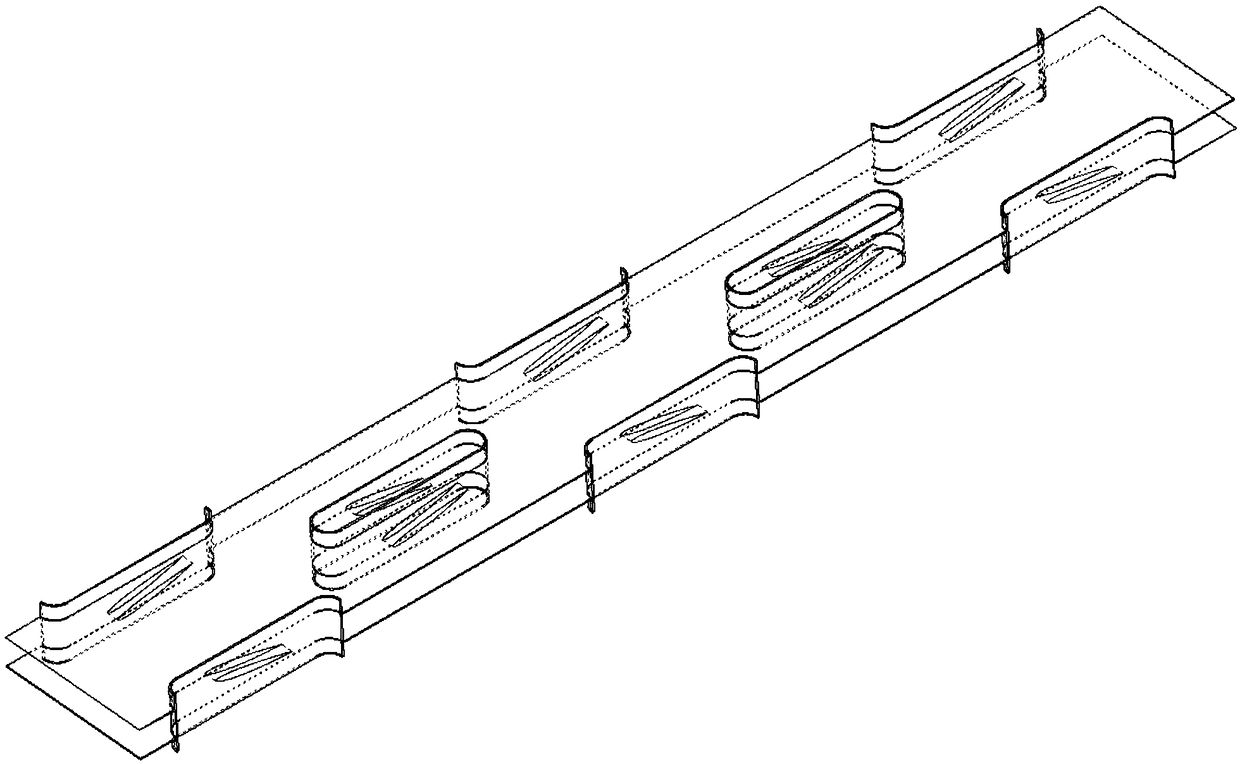

[0040] The heat pipe 2 stands on the ground or on a fixed stand; punch holes on the fin 1 according to the corresponding position of the heat pipe 2, and remove the punched material; after the hole position of the fin 1 is aligned with the heat pipe 2, insert the heat pipe 2, After inserting, arrange them in specific positions sequentially from bottom to top; the outer geometric features of the guide rudder 3 are processed into a symmetrical aircraft airfoil. Fixed on both sides of the heat pipe 2, if the thickness is small, the surface geometry features are retained, and the side of the non-fixed end is not closed; the fin 1 and the guide rudder 3 are installed in an alternating order; after the installation is completed, the fin 1, heat pipe 2 and The steering rudder 3 is integrally brazed to ensure structural strength.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com