Method for welding platinum target material and back plate

A welding method and backplane technology, applied in welding equipment, auxiliary devices, manufacturing tools, etc., can solve the problems of unfavorable target structure, high cost, and high equipment cost, increase cost and manufacturing cycle, enhance welding strength, control good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

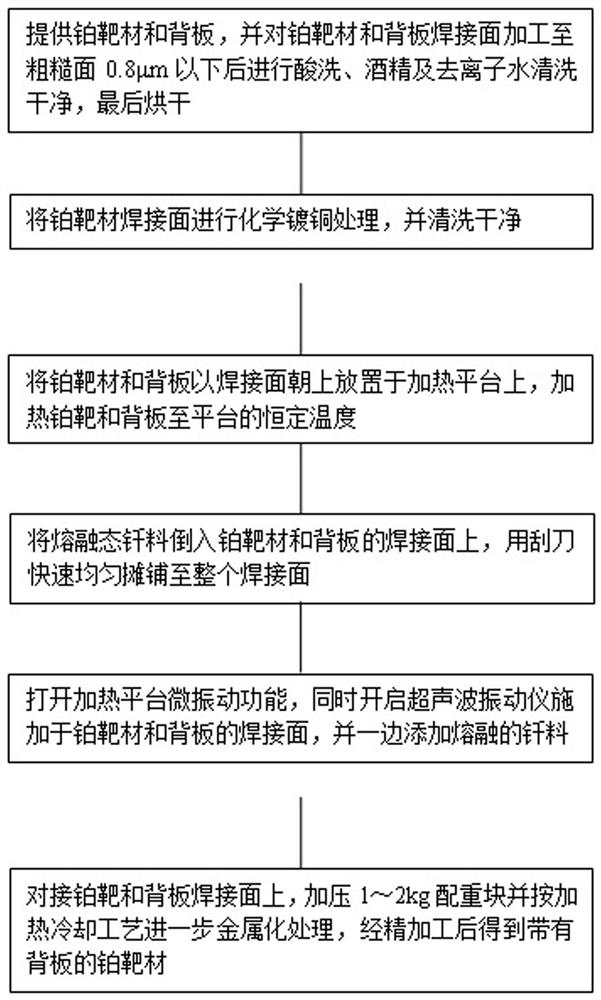

[0031] A pure platinum target and back plate welding method, its specific implementation technical steps are as follows:

[0032] (1) After the welding surface of the pure platinum target and the back plate is precisely processed, it is washed with pickling, alcohol and deionized water to remove the oil and impurities of the pure platinum target and the back plate, and obtain a welding surface with a roughness of 0.8 μm.

[0033] (2) Electroless copper plating is performed on the welding surface of the pure platinum target, the thickness of the copper plating layer is 0.15mm, and the welding surface is cleaned.

[0034] (3) Place the pure platinum target and the back plate on the heating platform with the welding side facing up, turn on the heating platform temperature to 170°C, so that the temperature of the pure platinum target and the back plate reaches the platform temperature evenly.

[0035] (4) Pour the molten solder into the welding surface of the pure platinum target ...

Embodiment 2

[0039] A method for welding a platinum-nickel alloy material and a back plate, the specific implementation technical steps are as follows:

[0040] (1) After the welding surface of the platinum-nickel alloy target and the back plate is precisely processed, it is cleaned with pickling, alcohol and deionized water to remove the oily impurities on the platinum-nickel alloy target and the back plate, and obtain a weld with a roughness of 0.6 μm noodle.

[0041] (2) Electroless copper plating is performed on the welding surface of the platinum-nickel alloy target, the thickness of the copper plating layer is 0.12mm, and the welding surface is cleaned.

[0042] (3) Place the platinum-nickel alloy target and the back plate on the heating platform with the welding side facing up, turn on the heating platform temperature to 180°C, so that the temperature of the platinum-nickel alloy target and the back plate evenly reaches the platform temperature.

[0043](4) Pour the molten solder i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com