Element-doped and double-layer-coated positive electrode material, preparation method thereof and lithium battery

A positive electrode material, double-layer coating technology, applied in the direction of lithium battery, positive electrode, battery electrode, etc., to achieve the effect of improving discharge capacity, easy mass production, and preventing dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

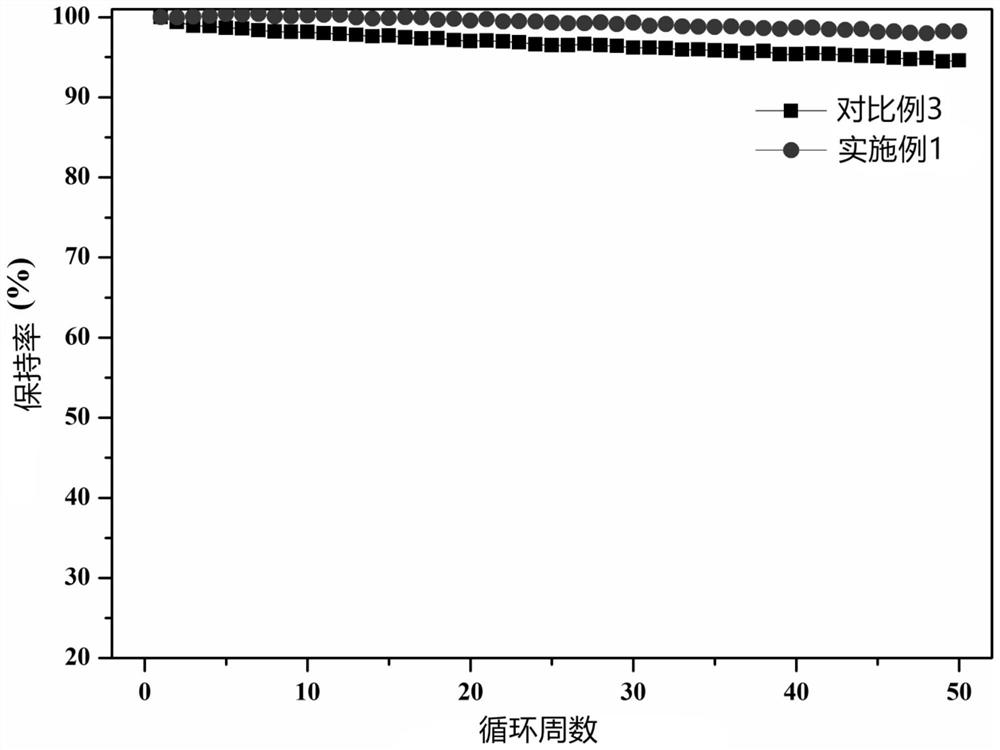

Embodiment 1

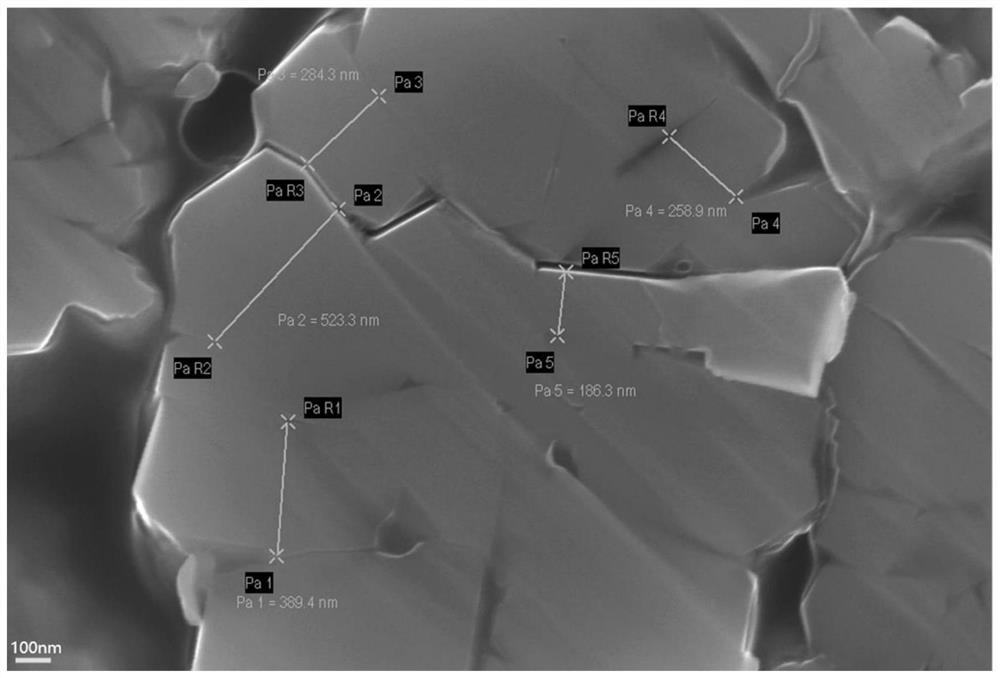

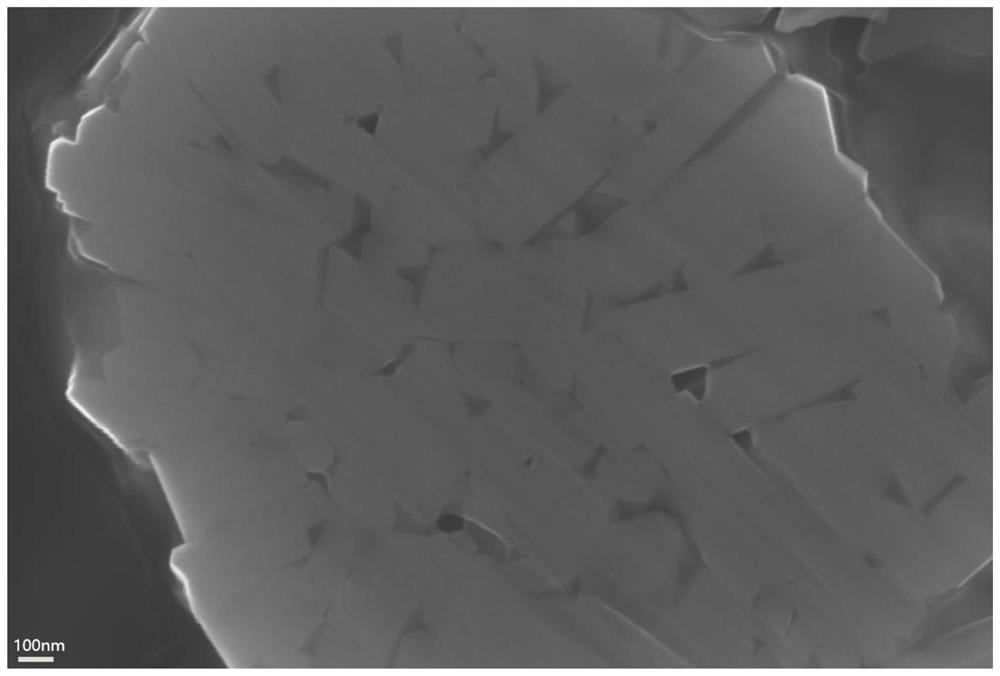

[0065] This embodiment provides a method for preparing an element-doped and double-layer coated positive electrode material. The preparation method includes the following steps:

[0066] (1) Lithium carbonate and precursor Ni 0.9 co 0.05 mn 0.05 (OH) 2 Mix according to the molar ratio of Li / (Ni+Co+Mn) of 1:1, and then add dopants containing zirconia, tantalum pentoxide and boron oxide, wherein zirconia accounts for the total mass of lithium carbonate and precursor 500ppm, tantalum pentoxide accounts for 500ppm of the total mass of lithium carbonate and the precursor, and boron oxide accounts for 2000ppm of the total mass of lithium carbonate and the precursor; lithium carbonate, the precursor and the dopant are mixed for 30min at a speed of 1500rpm to obtain mixed materials;

[0067] (2) Transfer the mixed material to a box-type atmosphere furnace, raise the temperature to 730 ° C at a heating rate of 2 ° C / min under an oxygen atmosphere, and keep it for 15 hours to obta...

Embodiment 2

[0071] This embodiment provides a method for preparing an element-doped and double-layer coated positive electrode material. The preparation method includes the following steps:

[0072] (1) Lithium chloride and precursor Ni 0.9 co 0.05 mn 0.05 (OH) 2 Mix according to the molar ratio of Li / (Ni+Co+Mn) of 1:1.02, and then add dopants containing zirconium hydroxide, tantalum phosphate and boric acid, wherein zirconium hydroxide accounts for the total mass of lithium chloride and precursor 500ppm, tantalum phosphate accounts for 2000ppm of the total mass of lithium chloride and the precursor, and boric acid accounts for 500ppm of the total mass of lithium chloride and the precursor; lithium chloride, the precursor and the dopant are mixed at a speed of 1800rpm for 26min to obtain mixed materials;

[0073] (2) Transfer the mixed material to a box-type atmosphere furnace, raise the temperature to 750 °C at a heating rate of 2.6 °C / min under an oxygen atmosphere, and keep it for ...

Embodiment 3

[0077] This embodiment provides a method for preparing an element-doped and double-layer coated positive electrode material. The preparation method includes the following steps:

[0078] (1) Lithium hydroxide and precursor Ni 0.9 co 0.05 mn 0.05 (OH) 2 Mix according to the molar ratio of Li / (Ni+Co+Mn) of 1:1.04, then add dopants containing zirconium nitrate, tantalum chloride and boron oxide, wherein zirconium nitrate accounts for the total mass of lithium hydroxide and precursor 800ppm, tantalum chloride accounts for 500ppm of the total mass of lithium hydroxide and precursor, and boron oxide accounts for 500ppm of the total mass of lithium hydroxide and precursor; lithium hydroxide, precursor and dopant are mixed at a speed of 2100rpm for 22min , to get the mixed material;

[0079] (2) Transfer the mixed material to a box-type atmosphere furnace, raise the temperature to 780°C at a heating rate of 3.2°C / min under an oxygen atmosphere, and keep it for 10 hours to obtain a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com