Fabricated part grouting layer plugging method and fabricated part connection construction method

A prefabricated, plugging technology, applied in building components, structural elements, building reinforcements, etc., can solve the problems of grouting sleeve grouting that cannot meet the requirements, cannot provide sufficient plugging force, and delay the progress of the project, etc. Achieve the effect of shortening the construction period, improving construction efficiency and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

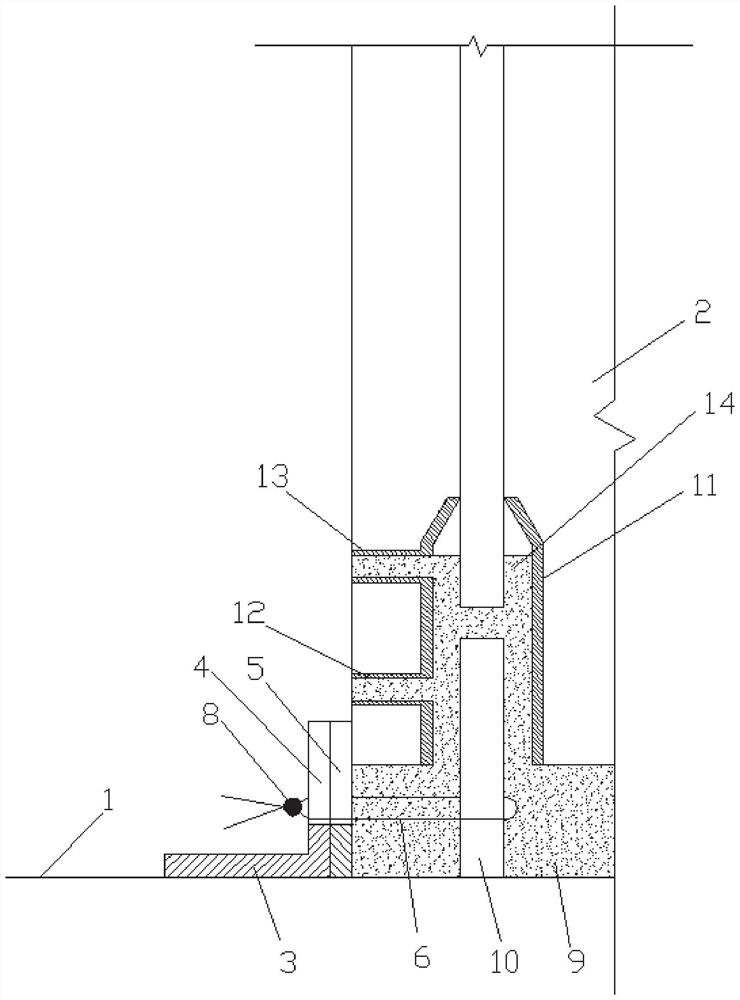

[0033] This embodiment discloses a method for sealing the grouting layer of an assembled component. The grouting layer formed by the joint between the pre-installed upper component and the lower component is sealed by using a sealing member.

[0034] In this embodiment, the lower component 1 is a floor slab, and the upper component 2 is a wall panel. In some other embodiments, the upper component can also be a column or the like.

[0035] In order to facilitate the movement of the blocking member, the blocking member is made of hard plastic, which is light in weight and has structural strength that meets requirements.

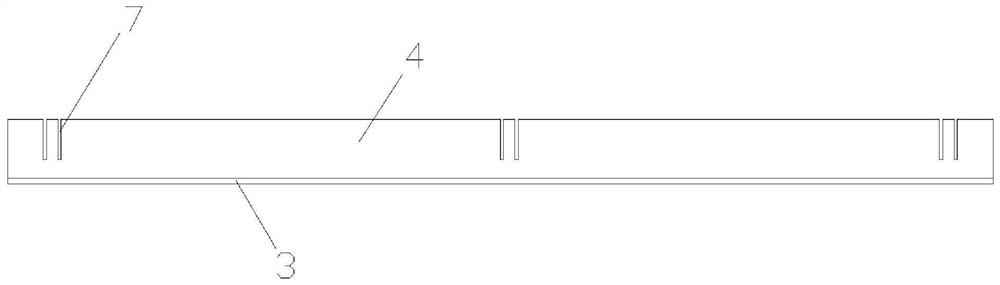

[0036] Such as figure 2 As shown, in this embodiment, the blocking member adopts an L-shaped plate, including a horizontal plate 3 and a vertical plate 4 integrally fixed at one end of the horizontal plate.

[0037] The horizontal plate is used to be placed on the upper surface of the lower member. In order to prevent the blocking member from hindering the gr...

Embodiment 2

[0051] This embodiment discloses a method for connecting assembled components, including the following steps:

[0052] Step a: Hoist the upper component 2 so that the pre-embedded steel bars 10 of the lower component extend into the pre-embedded grouting sleeve 11 of the upper component; the grouting sleeve includes a cylinder, and the cylinder is provided with a The grouting pipe 12 and the grouting pipe 13 on the side, the bottom end of the cylinder body is open and the bottom end is flush with the bottom end surface of the upper component.

[0053] Step b: The grouting layer formed by the joint between the upper component and the lower component is sealed by using the method for sealing the grouting layer of the assembled component described in Example 1;

[0054] In step c, the grouting sleeve is grouted through the grouting pipe of the grouting sleeve in the upper component, and the grouting material 14 is injected into the grouting sleeve and the grouting layer.

[0055...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com