A kind of high elastic modulus and high plasticity aluminum-silicon casting alloy and its preparation method and application

A casting alloy and high plasticity technology, applied in the field of casting aluminum alloy, can solve the problems such as the elastic modulus is only 72.4GPa, it is difficult to achieve elastic modulus and plasticity, and the elastic modulus is reduced, so as to achieve high strength, good plasticity, high The effect of the modulus of elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

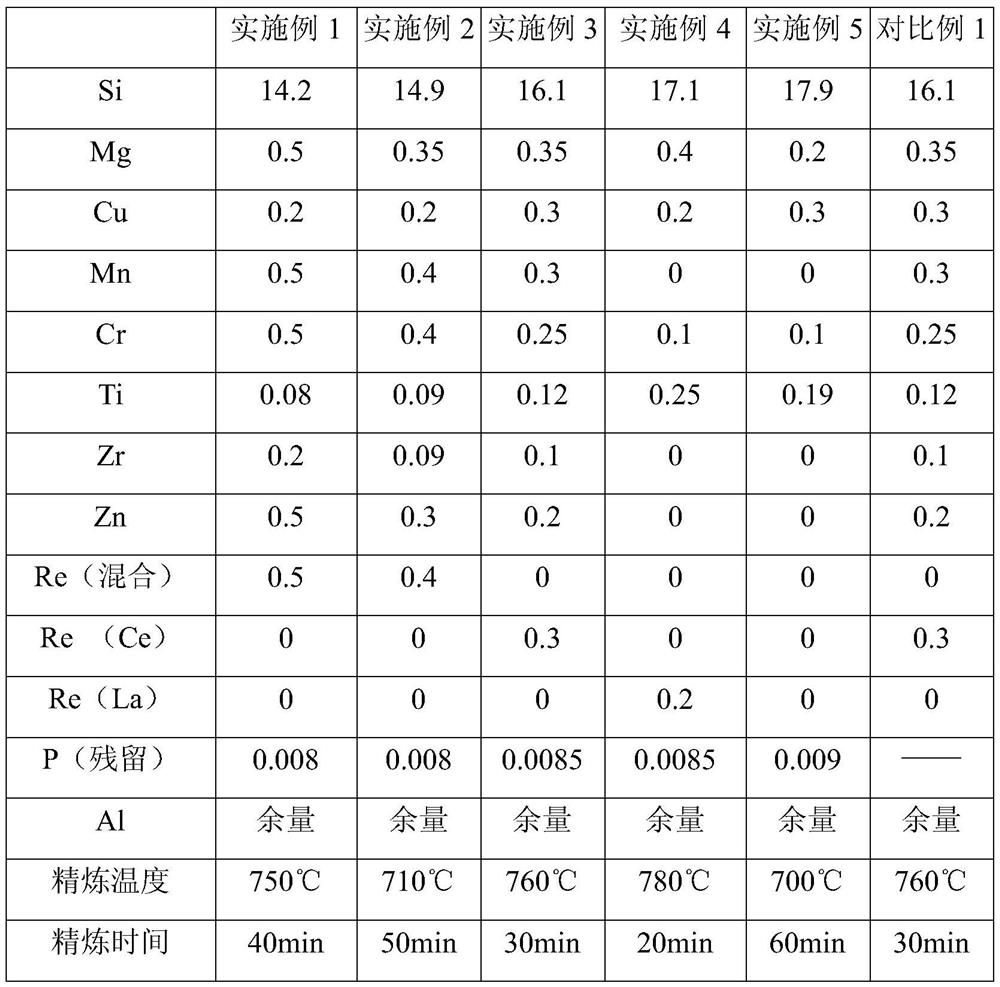

[0034] A high elastic modulus and high plasticity aluminum-silicon cast alloy, the composition and the mass percentage of each composition are shown in Table 1.

[0035] A preparation method of high elastic modulus and high plasticity aluminum-silicon casting alloy, comprising the following steps:

[0036] Prepare aluminum ingots and alloy raw materials. The aluminum ingots are selected from the Al99.70 aluminum ingots in the national standard GB / T 1196-2008 "Aluminum Ingots for Remelting", and the Al99.70 aluminum ingots are heated and melted to obtain an aluminum melt. The temperature is controlled at 680-800 ℃; other raw materials except Mg and P are added to the aluminum melt, and after the raw materials are melted, the Mg raw materials are added, and after the Mg raw materials are completely melted, stir evenly to obtain an alloy melt;

[0037]Add RJ-1 refining agent to the alloy melt, and carry out refining treatment. The refining temperature is 750°C and the refining ti...

Embodiment 2-5

[0041] Embodiment 2-5 is identical with embodiment 1, and the difference is:

[0042] The alloy composition is different. The alloy composition and the room temperature tensile properties of the prepared castings are shown in Table 1.

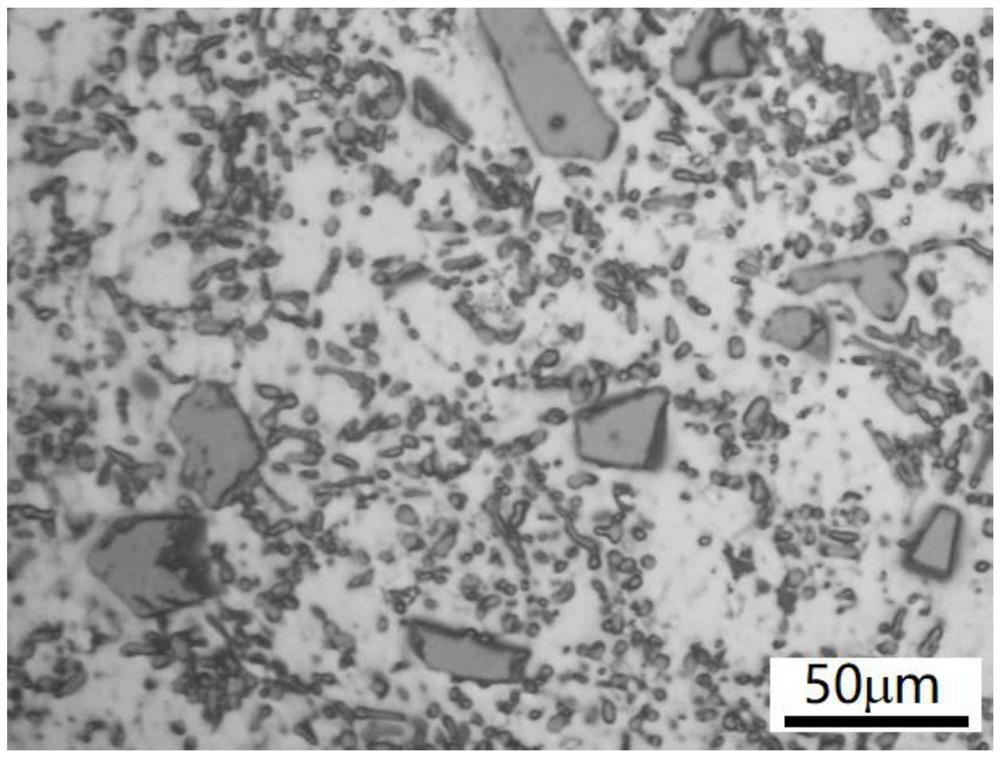

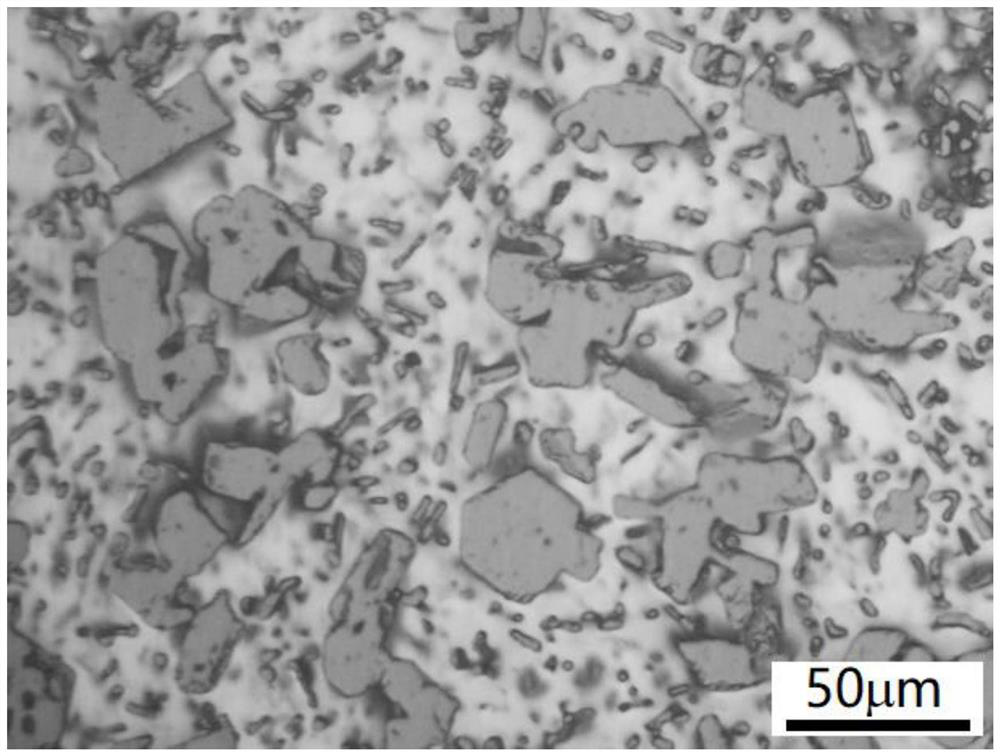

[0043] In addition, Comparative Example 1 is provided, and its alloy composition and preparation method are the same as those of Example 3. The difference is finally metamorphic processing link. This Comparative Example 1 did not use P modification, but used Sr modification. After the modification treatment, the residual amount of Sr in the alloy was 0.036%. The room temperature tensile properties are shown in Table 1. P is a modifier of hypereutectic Al-Si alloy, which has a good modification effect on primary silicon. But it has no metamorphic effect on eutectic silicon. Sr is a modifier of hypoeutectic Al-Si alloy, which has excellent modification effect on eutectic silicon, but has no modification effect on primary silicon. In this co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com