Composite thermistor material based on rare earth nickel-based oxide as well as preparation method and application of composite thermistor material

A thermistor and oxide technology, applied in the direction of resistance manufacturing, resistors with negative temperature coefficient, resistors, etc., can solve the problems of low material application cost, reduce the resistivity of thermistor materials, etc., and achieve low-dimensional The effect of realizing continuous regulation and suppressing inrush current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

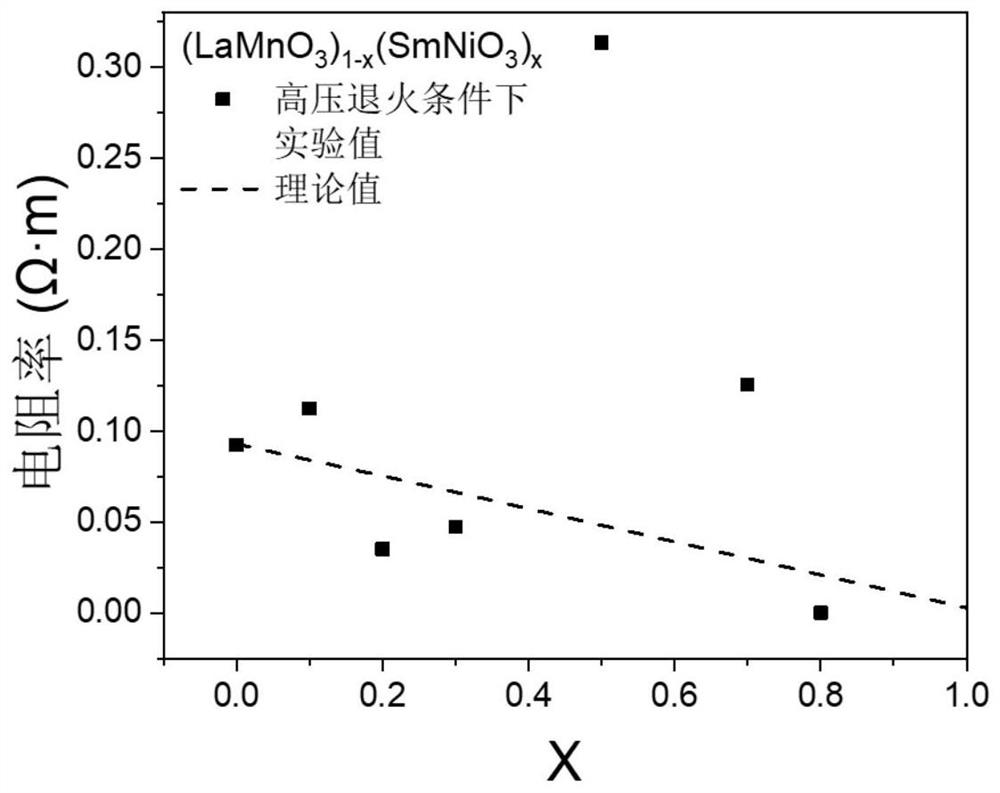

[0087] SmNiO 3 Powder and LaMnO synthesized by solid state reaction in air atmosphere 3 The powders were mixed and ground for 24 hours according to the ratio of 8:2, 5:5, 3:7, and 2:8. The selected Φ6, Φ10, and Φ20mm particle size grinding balls were 8, 3, and 2 respectively. The speed used was 1000r / min, heated to 1000°C in the air atmosphere for 12 hours, cold pressed at 500MPa to form a block, heated to 800°C in the air atmosphere for 24 hours, and compounded to obtain a composite thermistor. Calculated by simulation in the state of no interface resistance (LaMnO 3 ) 1-x -(SmNiO 3 ) x Composite thermistor room temperature resistivity comparison example figure 1 shown. figure 1 It shows that using the above-mentioned sintering process, a decrease in resistivity can be achieved at x=0.2, 0.7, 0.8, because the interface resistance is small at these ratios, but the resistivity increases at x=0.5, because the interface resistance at this time It is necessary to reduce the...

Embodiment 2

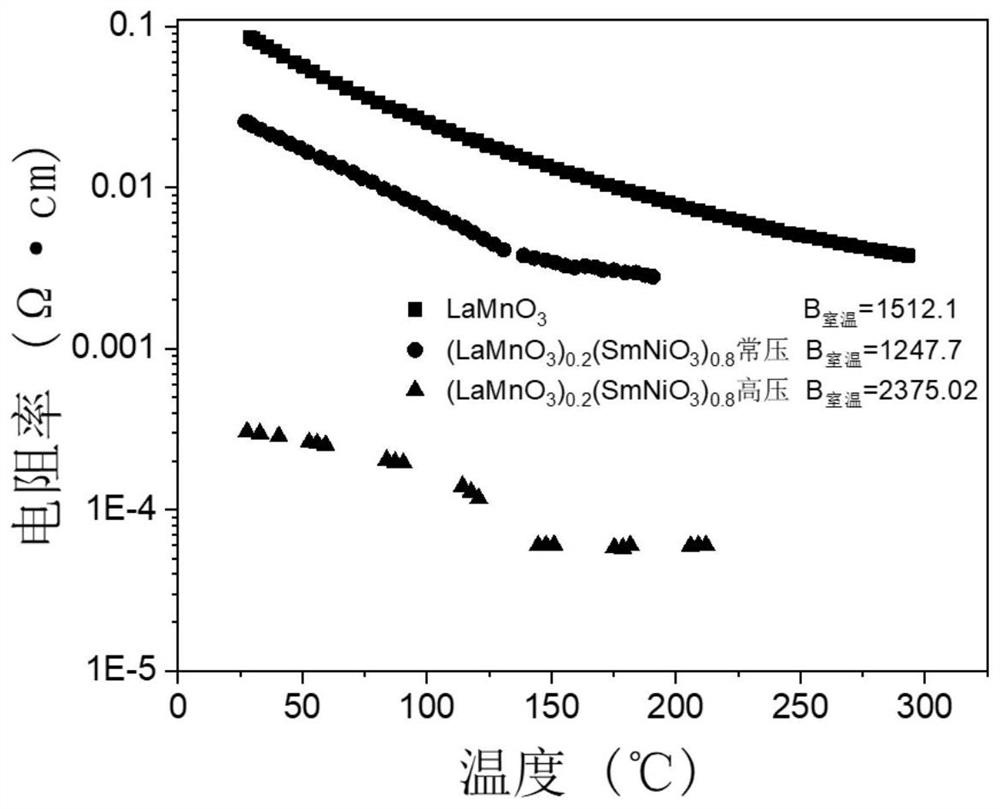

[0089] SmNiO 3 Powder and LaMnO synthesized by solid state reaction in air atmosphere 3 The powders were mixed and ground for 24 hours according to the molar ratio of 9:1, 8:2, 7:3, 5:5, 3:7, and 2:8, and the selected grinding balls with diameters of Φ6, Φ10, and Φ20mm were 8, 3 One or two, the speed used is 1000r / min, heated to 1000°C for 12 hours in an air atmosphere, cold-pressed at 500MPa to form a block, heated to 800°C for 24 hours under an oxygen atmosphere of 60 atmospheres , to obtain a composite thermistor bulk material, which is compared with (LaMnO 3 ) 1-x -(SmNiO 3 ) x Composite thermistor room temperature resistivity comparison example figure 2 shown. figure 2 shows that using the above sintering process a decrease in resistivity can be achieved at x = 0.2, 0.3, 0.8 due to the lower interfacial resistance at these ratios, but an increase in resistivity at x = 0.1, 0.5, 0.7 due to At this time, the interface resistance is high, and it is necessary to redu...

Embodiment 3

[0093] GdNiO 3 Powder and LaMnO synthesized by solid state reaction in air atmosphere 3 The powder is mixed and ground for 1 hour according to the molar ratio of 3:1. The selected Φ6, Φ10, and Φ20mm particle size grinding balls are 10, 2, and 2 respectively. The speed used is 10000r / min, and heated to 900 ℃ for 1 hour, add 5% mass fraction of PVA binder to the obtained powder and mix evenly, cold press it under 500MPa to form a block, and heat it to 800 ℃ for 1 hour in the air atmosphere to obtain a composite heat Varistor bulk material (LaMnO 3 ) 0.25 (GdNiO 3 ) 0.75 , the resistivity drops to 0.022Ω·m and the rate of change of resistivity further increases, which strengthens the characteristics of negative temperature coefficient thermistor. GdNiO 3 The powder regulates the resistance of other thermistor materials, effectively reducing the resistivity of high-resistivity NTC thermistor materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com