Preparation process and application of modified 3A molecular sieve

A molecular sieve and modified technology, applied in the field of molecular sieves, can solve the problems of low adsorption capacity, affect the operation of the system, and be prone to fragmentation, and achieve the effect of high-efficiency separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

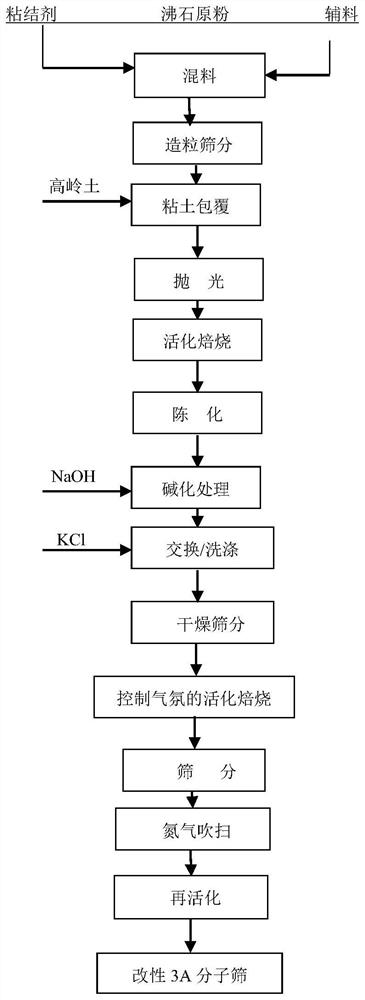

[0043] Wherein, the preparation method of modified 3A molecular sieve, technological process is as follows figure 2 shown, including the following steps:

[0044] (1) Ingredients: Mix halloysite, 4A zeolite and auxiliary materials to obtain a mixture. In the mixture, halloysite; the crystal size of 4A zeolite needs to be strictly controlled above 3 μm, preferably between 3 and 8 μm; The auxiliary material is sodium carboxymethyl cellulose, sodium cellulose or sodium lignosulfonate, and the added amount is 1%-3% of the total amount.

[0045] (2) Granulation and screening: the mixture is granulated and sieved to obtain molecular sieve particles with a diameter of 1.6-2.5mm; it can also be obtained with a diameter of 0.5-1.0mm, or 1.0-1.5mm, or 1.6-2.0mm molecular sieve particles.

[0046] (3) Coating with clay: Spray a small amount of water on the surface of the molecular sieve particles, and coat with kaolin powder. The thickness of the coating is less than 1 mm, for example...

Embodiment 1

[0063] The molecular sieve drying bed applicable to the four-bed molecular sieve carbon dioxide removal system in this embodiment is filled with silica-alumina gel and modified 3A molecular sieve, 50 g of silica-alumina gel is loaded at the inlet end of the drying bed, and 50 g of modified 3A molecular sieve is packed in outlet end.

[0064] Wherein, the preparation method of the modified 3A molecular sieve refers to the description of the above preparation method, and the process parameters and control indicators of the steps are explained as follows:

[0065] In step (1), during batching, kaolin 50kg, 4A zeolite 500kg. The particle size of 4A zeolite is 3-8 μm.

[0066] In step (2), molecular sieve particles with a diameter of 1.6-2.5 mm are obtained by granulating and sieving.

[0067] In step (7), the degree of potassium exchange is 32%.

[0068] In step (8), the firing atmosphere is air with a dew point of -20°C. The roasting temperature is 600°C, and the product cont...

Embodiment 2~6

[0071] The molecular sieve drying beds of Examples 2-6 differ from Example 1 only in the modified 3A molecular sieve, and the specific differences and related properties are listed in Table 1.

[0072] Table 1 Control indicators of the preparation method of modified 3A molecular sieves in Examples 1-6

[0073]

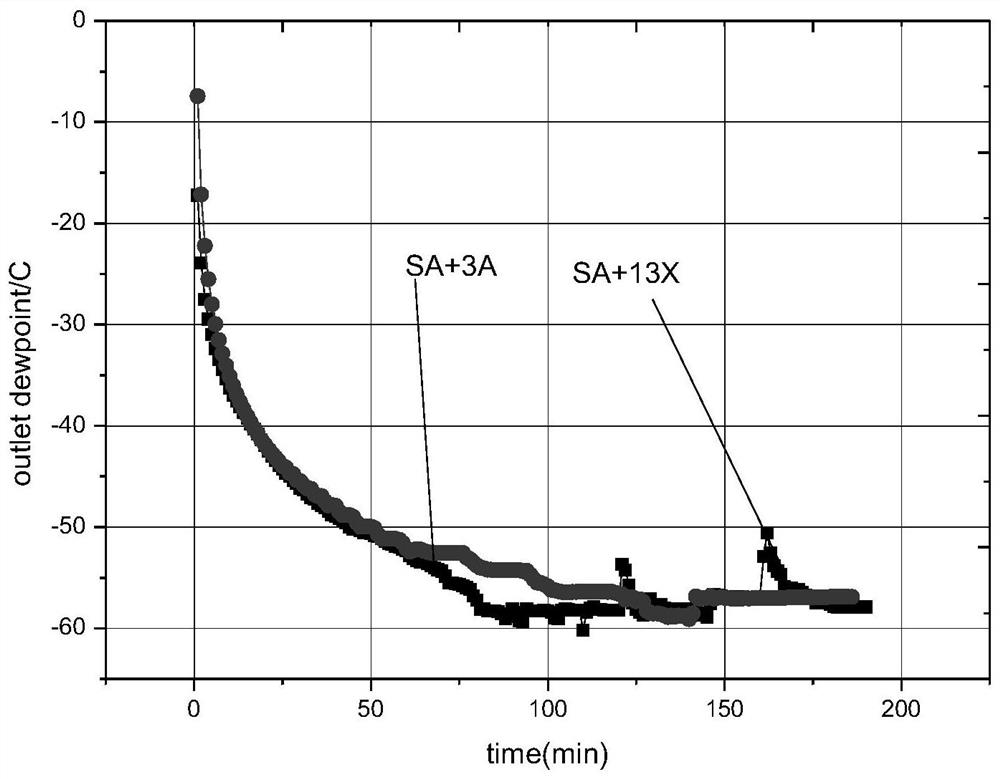

[0074] It can be seen from Table 1 that the modified 3A molecular sieves in Examples 1-6 can selectively absorb moisture in the air without substantially absorbing CO in the air. 2 . Among them, although the exchange degree of modified 3A4 is only 32%, after controlling the roasting atmosphere, the CO of the product 2 The adsorption performance drops below 0.5%, the product strength and wear are higher than those prepared under other conditions, and the comprehensive performance is the best, so the modified 3A4 sample is used as the benchmark sample for subsequent comparative tests and dynamic tests.

[0075] 2. The specific embodiment of the preparation method of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com