Resonance temperature sensitive chip probe of isolation packaging structure and packaging method thereof

A technology for sensitive chips and packaging structures, applied in microstructure devices, manufacturing microstructure devices, microelectronics microstructure devices, etc., can solve problems such as performance degradation, increased pressure in the sealed cavity, sensor failure, etc., to improve long-term stability. , the effect of improving stability and increasing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

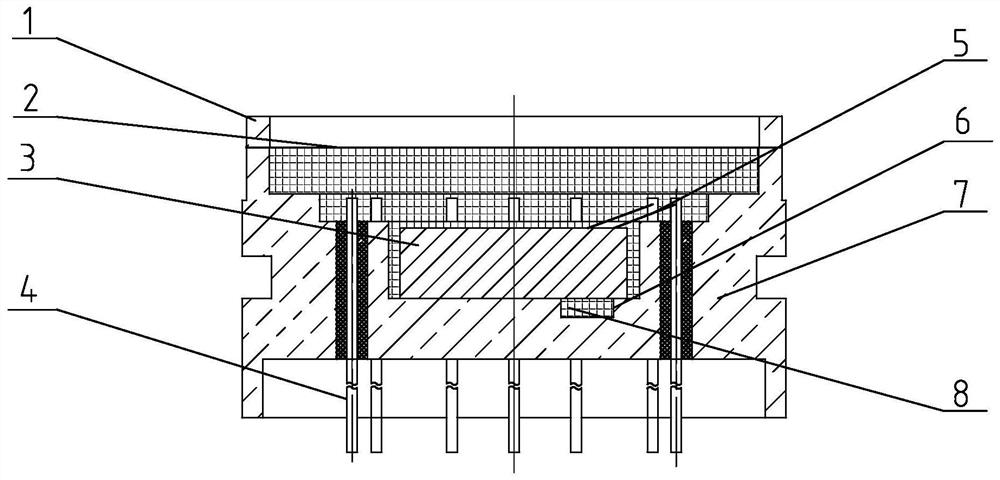

[0052] Specific implementation mode one: combine Figure 1 to Figure 8 Describe this embodiment, a resonant temperature-sensitive chip probe with an isolated package structure in this embodiment includes a pressure ring 1, a flat diaphragm 2, a silicon resonant temperature-sensitive chip 3, Kovar pins 4, electrode bonding wires 5, Probe medium transmission channel 6, sealing tube base 7 and isolation medium 8,

[0053] The silicon resonant temperature-sensitive chip 3 includes a chip upper cover 301, a resonant layer 302, a silicon-based substrate 3021, and a stress isolation layer 303. The chip upper cover 301, the resonant layer 302, the silicon-based substrate 3021, and the stress isolation layer 303 are arranged from top to bottom connected in turn and made into one body, the lower end surface of the silicon-based substrate 3021 is horizontal, wherein an absolute pressure chamber is formed between the chip upper cover 301 and the silicon-based substrate 3021, and the reson...

specific Embodiment approach 2

[0057] Specific implementation mode two: combination Figure 4 To describe this embodiment, a temperature-sensing through hole 3031 is opened in the middle of the stress isolation layer 303 of this embodiment. Such setting facilitates the transmission of pressure to the silicon-based substrate 3021 and then to the resonant layer 302 to achieve the purpose of pressure sensing. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0058] Specific implementation mode three: combination Figure 8 To illustrate this embodiment, the resonant layer 302 of this embodiment includes four extraction electrodes 3022, two driving electrodes 3023, a spare electrode 3024, two sensitive comb electrodes 3025, two stabilizing beams 3026, two transverse tension beams 3027, Anchor block 3028 and electrode channel 3029, two driving electrodes 3023 are arranged in parallel up and down, and an extraction electrode 3022 is installed on the left and right sides of each driving electrode 3023, and a sensitive comb electrode is installed on the opposite side of the two driving electrodes 3023 3025, a stabilizing beam 3026 is installed on the inner side of the two sensitive comb electrodes 3025, a transverse tension beam 3027 is respectively installed on the inner side of the two stabilizing beams 3026, and an anchor block 3028 is installed between the two transverse tension beams 3027, The anchor block 3028 is connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com