Non-autoclave electroforming composite material method based on carbon nanomaterial

A technology of carbon nanomaterials and composite materials, which is applied in the field of composite material structure molding, can solve problems such as unspecified thickness and resin film adhesion of complex special-shaped parts, so as to improve the uniformity of temperature field and improve the quality and efficiency of molding , Improve the effect of temperature conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

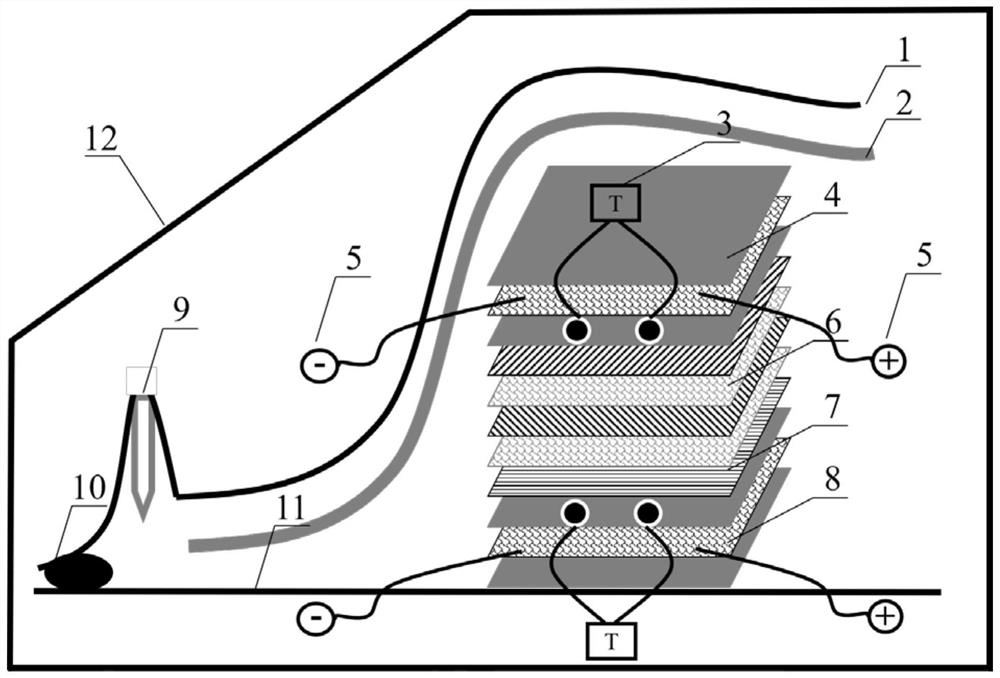

[0049] Embodiments of the present invention relate to a non-autoclave electroforming composite method based on carbon nanomaterials, such as figure 1 As shown, it includes a vacuum bag 1, an air felt 2, a thermocouple and its host 3, a non-porous Teflon film 4, a high voltage generator 5, a thin layer of highly oriented multi-walled carbon nanotubes with a diameter of 5-10 nm and a thickness of 20 μm 6 , Hexcel AS4 / 8552 aviation-grade carbon fiber unidirectional tape prepreg 7, sheet resistance ~ 5Ω / port, thickness 40μm carbon nanotube resistance heater 8, vacuum valve 9, sealing putty 10, bottom plate 11, heat insulation layer 12.

[0050] Using the device and method of the present invention to solidify a Hexcel AS4 / 8552 carbon fiber unidirectional tape prepreg commonly used on the rear fuselage skin of an aviation civil aircraft, the steps are as follows.

[0051] S1. Lay non-porous Teflon film 4, carbon nanotube resistance heater 8, and non-porous Teflon film 4 on the bott...

Embodiment 2

[0068] Embodiments of the present invention relate to a non-autoclave electroforming composite method based on carbon nanomaterials, such as figure 1 As shown, it includes vacuum bag 1, air felt 2, thermocouple and its host 3, non-porous Teflon film 4, high voltage generator 5, continuous carbon nanofiber film 6 with a diameter of 300nm and a thickness of 22μm, Lily Aerospace T300 / Epoxy resin carbon fiber unidirectional tape prepreg 7, sheet resistance ~ 5Ω / port, 40 μm thick carbon nanotube resistance heater 8, vacuum valve 9, sealing putty 10, bottom plate 11, heat insulation layer 12.

[0069] Use the device and method of the present invention to cure a commonly used Lily Aerospace T300 / epoxy resin carbon fiber unidirectional tape prepreg, and compare its interlaminar mode II fracture toughness G ⅡC performance, the steps are as follows.

[0070] S1. Lay non-porous Teflon film 4, carbon nanotube resistance heater 8, and non-porous Teflon film 4 on the bottom plate 11 in o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com