Application and method of manganese peroxidase in degradation of patulin

A technology of manganese peroxidase and patulin, which is applied in the application field of degrading patulin, can solve the problems of less patulin degrading enzyme and the like, and achieves the effects of low cost and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1 Preparation of recombinant manganese peroxidase MrMnP

[0017] The MrMnP gene sequence from Moniliophthora roreri was fully synthesized from Jinweizhi Company. The X33 / MrMnP Pichia pastoris engineering strain containing the recombinant plasmid was inoculated in 50 mL of YPD medium, shaken at 30 °C and 220 rpm for 48 h, and then transferred to 300 mL of BMGY medium at a ratio of 2%, at 30 °C. , 220 rpm shaking culture for 48 h, the BMGY yeast culture solution was centrifuged at 5,500 rpm for 5 min, and the supernatant was discarded. Add 200 mL of BMMY medium (with the addition of heme at a final concentration of 100 µM) to the fermentation flask. Cultivate on a shaker at 30°C for 48 hours at 200 rpm, centrifuge at 5,500 rpm for 5 minutes, collect the fermentation broth, and prepare the recombinant manganese peroxidase MrMnP.

Embodiment 2

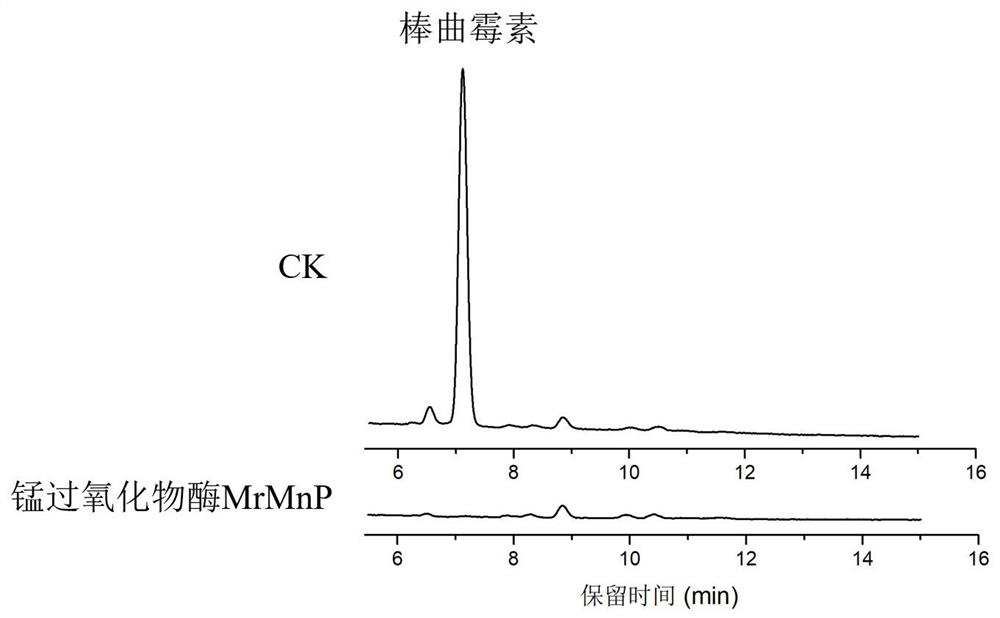

[0018] Example 2 Degradation of patulin by manganese peroxidase

[0019] Dissolve patulin in acetonitrile to prepare a 5 g / L stock solution, and use the following reaction system: 250 μL malonic acid buffer (0.2 M, pH 5.0), 100 μL patulin solution (50 mg / L ), 250 μL manganese sulfate (40 mM), 250 μL manganese peroxidase (5000 U / L) prepared in Example 1, 200 μL hydrogen peroxide (5 mM). The system without adding manganese peroxidase was used as a control, and the reaction system was repeated three times. The reaction was carried out at 30°C. After 12 h, three times the volume of methanol was added to terminate the reaction. The degradation rate of patulin was analyzed by high performance liquid chromatography (HPLC). The liquid chromatography is Shimadzu Nexera UHPLC high-performance liquid chromatography analysis system, the chromatographic separation column is Zorbax SB-C18 (4.6×250 mm, 5 μm), mobile phase A (water with 0.1% acetic acid), mobile phase B (acetonitrile) ; Elu...

Embodiment 3

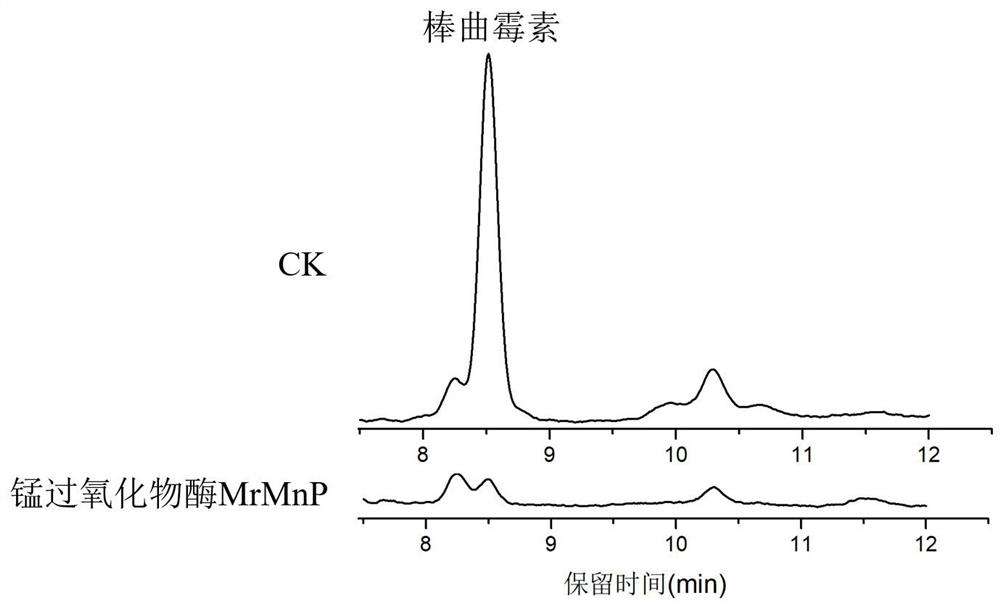

[0020] Example 3 Degradation of patulin in fruit juice by manganese peroxidase

[0021] Dissolve patulin in acetonitrile to prepare a 5g / L stock solution, and follow the following reaction system: 250 μL malonic acid buffer (0.2 M, pH 5.0, apple juice as solvent), 25 μL patulin solution ( 200 mg / L), 250 μL manganese sulfate (40 mM, apple juice as solvent), 125 μL manganese peroxidase (10000 U / L) prepared in Example 1, 100 μL hydrogen peroxide (10 mM), 250 μL apple juice. The system without adding manganese peroxidase was used as a control, and the reaction system was repeated three times. The reaction was carried out at 30°C. After 24 h, three times the volume of methanol was added to terminate the reaction. The degradation rate of patulin was analyzed by high performance liquid chromatography (HPLC). The liquid chromatography is Shimadzu Nexera UHPLC high-performance liquid chromatography analysis system, the chromatographic separation column is ZorbaxSB-C18 (4.6×250 mm, 5 μ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com