Powder metallurgy drying equipment for metal product production

A technology for powder metallurgy and metal products, applied in the field of powder metallurgy drying equipment for metal product production, can solve the problems of difficult rapid cooling, unfavorable drying operation, difficult metal powder turning, etc., and achieves the effect of improving drying balance and shortening cooling time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

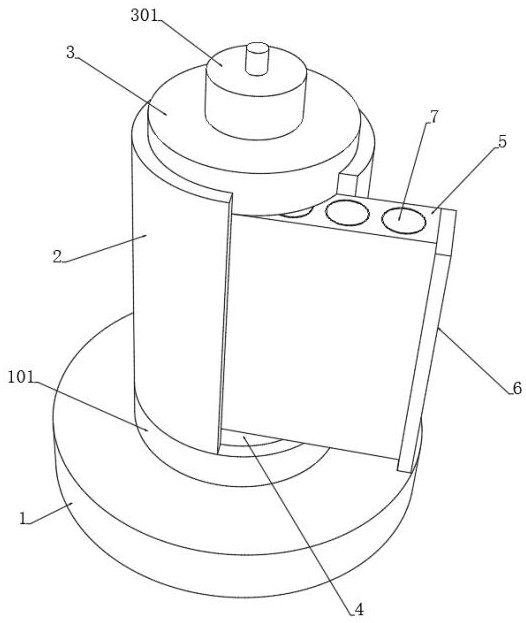

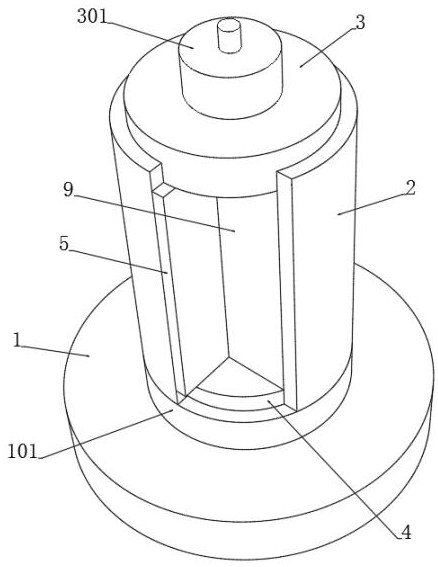

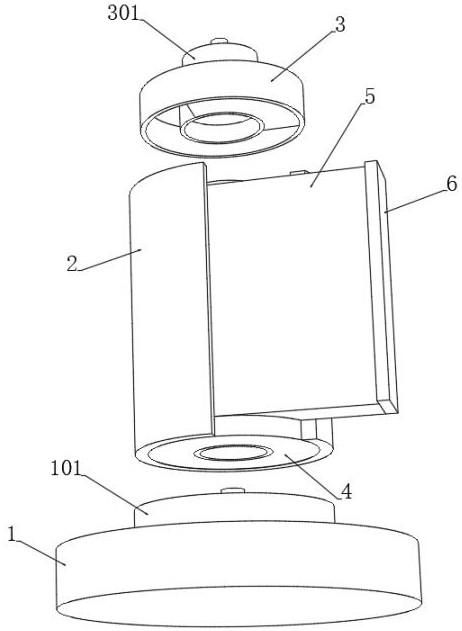

[0045] see Figure 1-4 , a powder metallurgy drying equipment for the production of metal products, comprising a lower base 1 and a drying sleeve rotatably mounted on the lower base 1, the drying sleeve is composed of a drying inner cylinder 8 and a drying outer cylinder 2 set inside and outside, and the drying inner A heater is installed in the cylinder 8, and the heater adopts a heating block or a heating rod in the prior art. The bottom of the drying outer cylinder 2 is fixedly connected with an upper base 101, and the upper base 101 is installed in the upper base 101 to rotate the drying inner cylinder 8. A motor, the upper base 101 is rotatably installed on the lower base 1, and the second motor that rotates the upper base 101 is installed in the lower base 1, and the second motor drives the drying outer cylinder 2 and the drying inner cylinder 8 to rotate. The upper and lower ends of the drying outer cylinder 2 are respectively sleeved with an upper cover 3 and a lower c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com