Method for preparing anti-fingerprint black film on the basis of PVD (Physical Vapor Deposition) and film coated part

A black film, anti-fingerprint technology, applied in the field of methods and coated parts, can solve the problems of human body and environmental hazards, non-abrasive paint layer, high processing cost, and achieve the effects of low cost, excellent compactness and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

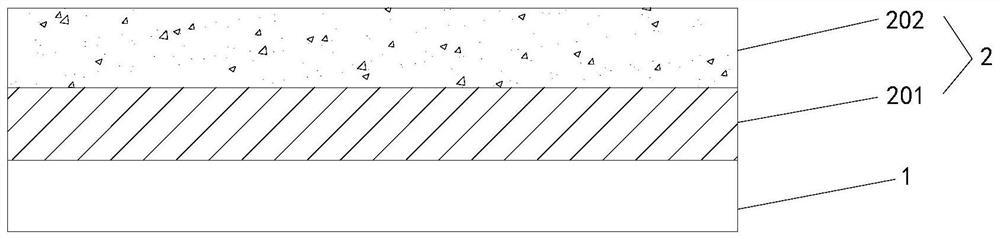

Image

Examples

Embodiment 1

[0037] S1. Pretreatment of the parts to be plated: clean the oil stains on the surface of the parts to be plated with sulfuric acid solution and remove the oxide film on the surface of the parts to be plated, and then put the parts to be plated into a vacuum furnace;

[0038] S2. Cleaning of the parts to be plated: evacuate the vacuum furnace, heat up to 130°C, fill with Ar, start the Ti arc target, and perform plasma cleaning on the parts to be plated under the bias voltage of -700V in the vacuum furnace;

[0039] S3. Bottom film: close the Ti arc target, start the TiCrAl sputtering target, continue to fill Ar, load -70V bias, and deposit the TiCrAl film bottom film on the surface of the workpiece to be plated; during the deposition process of the bottom film, the pressure in the vacuum furnace 6.0×10 -3 , the flow rate of Ar is 100 sccm, the target current is 5A, the electroplating time is 5 minutes, and the thickness of the underlying film is 0.03 μm;

[0040] S4, black fi...

Embodiment 2

[0042] S1. Pretreatment of the parts to be plated: clean the oil stains on the surface of the parts to be plated with sulfuric acid solution and remove the oxide film on the surface of the parts to be plated, and then put the parts to be plated into a vacuum furnace;

[0043] S2. Cleaning of the parts to be plated: vacuumize the vacuum furnace, raise the temperature to 140 ° C, fill with Ar, start the Ti arc target, and perform plasma cleaning on the parts to be plated under the bias voltage of -800V in the vacuum furnace;

[0044] S3. Bottom film: close the Ti arc target, start the TiCrAl sputtering target, continue to fill Ar, load -80V bias, and deposit the TiCrAl film bottom film on the surface of the workpiece to be plated; during the deposition process of the bottom film, the pressure in the vacuum furnace 7.0×10 -3, the flow rate of Ar is 200sccm, the target current is 8A, the electroplating time is 6 minutes, and the thickness of the underlying film is 0.04μm;

[0045...

Embodiment 3

[0047] S1. Pretreatment of the parts to be plated: clean the oil stains on the surface of the parts to be plated with sulfuric acid solution and remove the oxide film on the surface of the parts to be plated, and then put the parts to be plated into a vacuum furnace;

[0048] S2. Cleaning of the parts to be plated: evacuate the vacuum furnace, heat up to 150°C, fill with Ar, start the Ti arc target, and perform plasma cleaning on the parts to be plated under the bias voltage of -900V in the vacuum furnace;

[0049] S3. Bottom film: close the Ti arc target, start the TiCrAl sputtering target, continue to fill Ar, load -85V bias, and deposit the TiCrAl film bottom film on the surface of the workpiece to be plated; during the deposition process of the bottom film, the pressure in the vacuum furnace 7.5×10 -3 , the flow rate of Ar is 230sccm, the target current is 7A, the electroplating time is 7 minutes, and the thickness of the bottom film is 0.05μm;

[0050] S4, black film: cl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com