A method for preparing nanometer ellipsoidal calcium carbonate particles

A calcium carbonate and ellipsoid technology is applied in the field of preparation of nano-ellipsoid calcium carbonate particles to achieve the effects of reducing energy consumption, large surface area and lowering production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

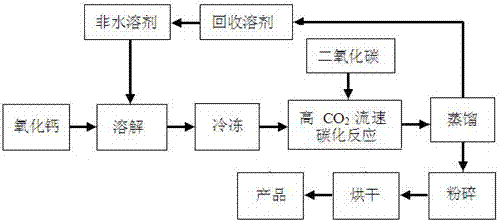

[0028] A kind of preparation method of nanometer ellipsoidal calcium carbonate particle, concrete processing step is as follows:

[0029] (1) Add 20 parts by mass of calcium oxide to 100 parts of a mixed solvent of ethanol and butanol with a mass ratio of 3.8:1, and stir to prepare Ca(OH) 2 suspension, and then cool the suspension to 10°C in an ice bath;

[0030] (2) The cooled Ca(OH) 2 The suspension is sent to the carbonization reactor. At room temperature, carbon dioxide is blown from the bottom of the carbonization reactor at a large flow rate of 200mL / min. When the pH=7, the CO2 injection is stopped. 2 , then transferred to a vacuum distiller, heated to 75°C, and the pressure was -1.3KPa, and the solvent was recovered to obtain nanometer calcium carbonate solid particles;

[0031] (3) The calcium carbonate solid particles are pulverized by conventional methods to obtain nano-elliptical calcium carbonate products.

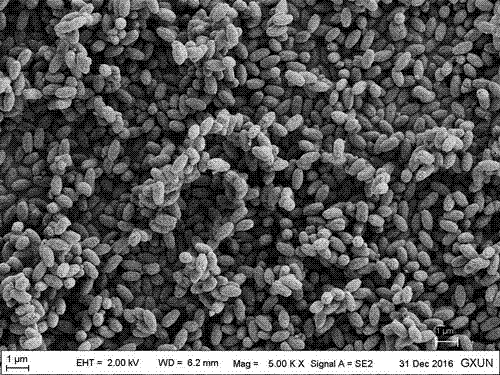

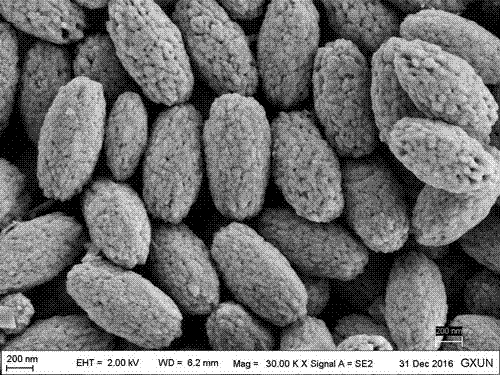

[0032] The bulk density of the nano-ellipsoidal calciu...

Embodiment 2

[0034] A kind of preparation method of nanometer ellipsoidal calcium carbonate particle, concrete processing step is as follows:

[0035] (1) Add 20 parts by mass of calcium oxide to 200 parts of methanol and glycerol mixed solvent with a mass ratio of 2.5:1, and stir to prepare Ca(OH) 2 suspension, and then cool the suspension to 7°C in an ice bath;

[0036] (2) The cooled Ca(OH) 2 The suspension is sent to the carbonization reactor. At room temperature, carbon dioxide is blown from the bottom of the carbonization reactor at a large flow rate of 250mL / min. When the pH=7.5, the CO2 is stopped. 2 , then transferred to a stirred atmospheric distiller, stirring at a rotating speed of 70r / min, heating to 170°C, recovering the solvent, recovering the solvent, and obtaining nanometer calcium carbonate solid particles;

[0037] (3) The calcium carbonate solid particles are pulverized by conventional methods to obtain nano-elliptical calcium carbonate products.

[0038] The bulk de...

Embodiment 3

[0040] A kind of preparation method of nanometer ellipsoidal calcium carbonate particle, concrete processing step is as follows:

[0041](1) Add 20 parts by mass of calcium oxide to 150 parts of a mixed solvent of methanol and acetonitrile with a mass ratio of 3.5:1, and stir to prepare Ca(OH) 2 suspension, and then cool the suspension to 8°C in an ice bath;

[0042] (2) The cooled Ca(OH) 2 The suspension is sent to the carbonization reactor. At room temperature, carbon dioxide is blown from the bottom of the carbonization reactor at a large flow rate of 300mL / min. When the pH=7.2, the CO2 is stopped. 2 , then transferred to a stirred atmospheric distiller, stirred at a rotating speed of 100r / min, heated to 75°C, recovered the solvent, and obtained nanometer calcium carbonate solid particles;

[0043] (3) The calcium carbonate solid particles are pulverized by conventional methods to obtain nano-elliptical calcium carbonate products.

[0044] The bulk density of the nano-el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com