Guide pin positioning guide plate customization and simulation verification system and method thereof

A simulation verification and positioning-oriented technology, applied in the field of fracture medical system, can solve the problems of inaccurate positioning of the guide pin, long operation time, death, etc., and achieve the effect of improving production quality and efficiency, increasing the success rate of operation, and improving the quality of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

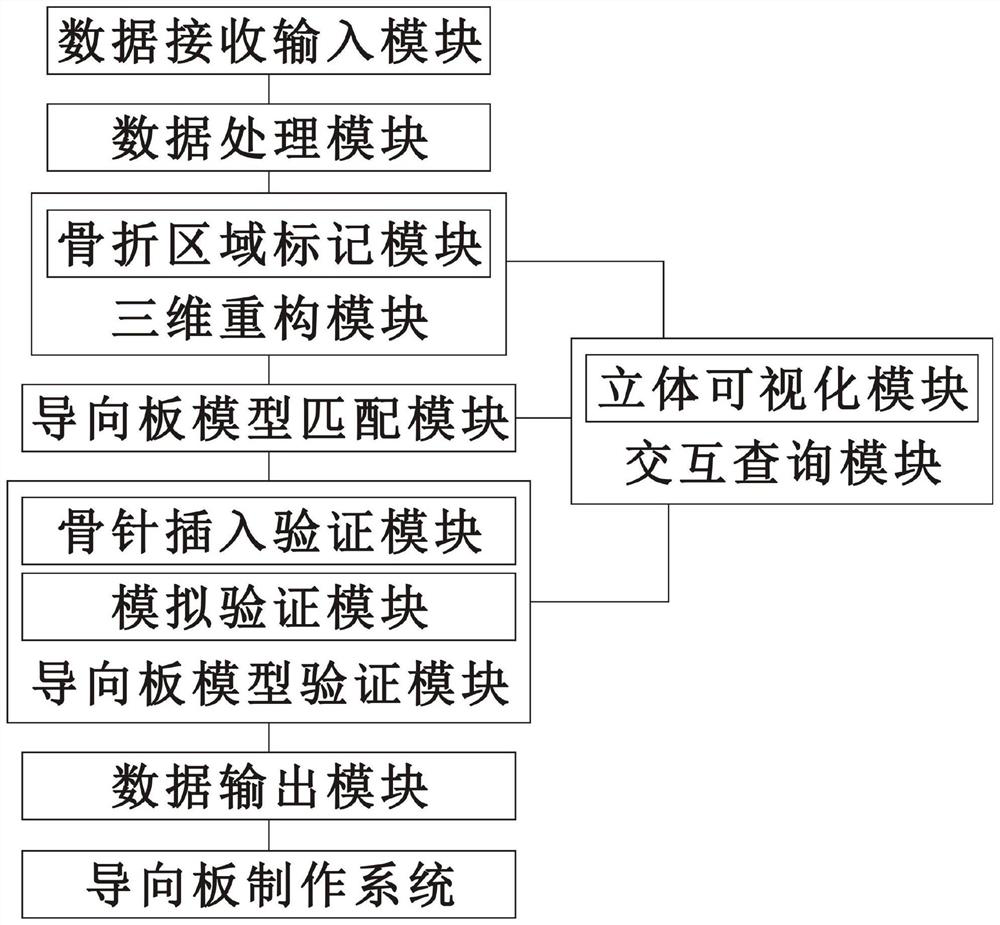

[0034] Such as Figure 1 to Figure 5As shown, a guide pin positioning guide plate customization and simulation verification system includes a data receiving and input module, a data processing module, a three-dimensional reconstruction module, a guide plate model matching module, a guide plate model verification module, a data output module, and a guide plate production module. System and interactive query module, data receiving and input module, data processing module, 3D reconstruction module, guide plate model matching module, guide plate model verification module, data output module, and guide plate production system are connected in sequence, and the interactive query module is connected with the 3D reconstruction module respectively. The structure module, the guide plate model matching module, and the guide plate model verification module are connected. The data receiving and input module is used to receive and input CT data in DICOM format, the data processing module ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com