Ultraviolet irradiation mechanism for optical fiber curing

A technology of irradiation mechanism and ultraviolet light, which is applied in the direction of pretreatment surface, device for coating liquid on the surface, coating, etc., can solve problems such as uneven intensity, and achieve the effect of improving uneven intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

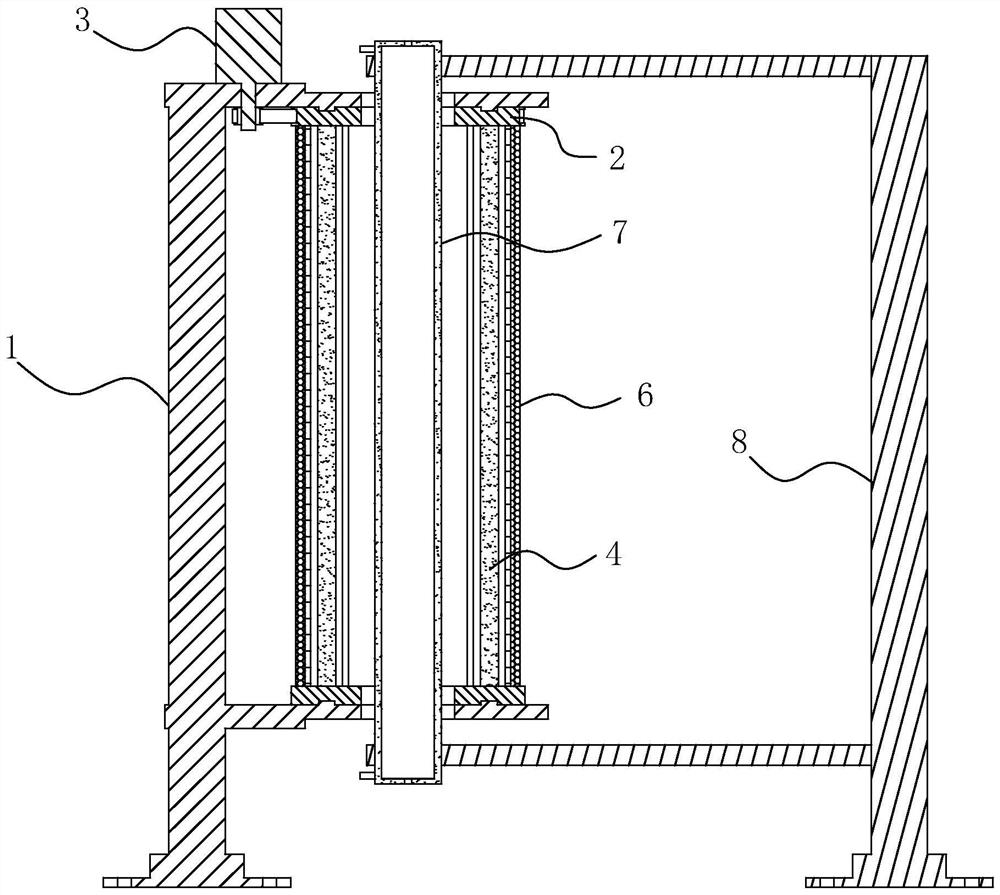

[0032] The following is attached Figure 1-4 The application is described in further detail.

[0033] The embodiment of the present application discloses an ultraviolet light irradiation mechanism for optical fiber curing. refer to figure 1 and figure 2 , an ultraviolet light irradiation mechanism for optical fiber curing includes an illumination support assembly 1, a rotation assembly 2, a drive assembly 3 and a light source assembly 4 for emitting ultraviolet light. The illumination support assembly 1 is fixed on the concrete floor in the factory, and the illumination support assembly Component 1 plays the role of supporting and fixing, and is used to support rotating component 2. The rotating assembly 2 is rotatably installed on the lighting support assembly 1, and the rotating assembly 2 is used to support the light source assembly 4 and provide a stable installation environment for the light source assembly 4, while driving the light source assembly 4 to rotate. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com