Heat-resisting polyethylene composite pipe and preparation method thereof

A technology of heat-resistant polyethylene and composite pipes, applied in the direction of hoses, pipes, mechanical equipment, etc., can solve the problems of unsuitable pipe extrusion, high material viscosity, and difficult realization, etc., and achieve simple structure, long service life, The effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing.

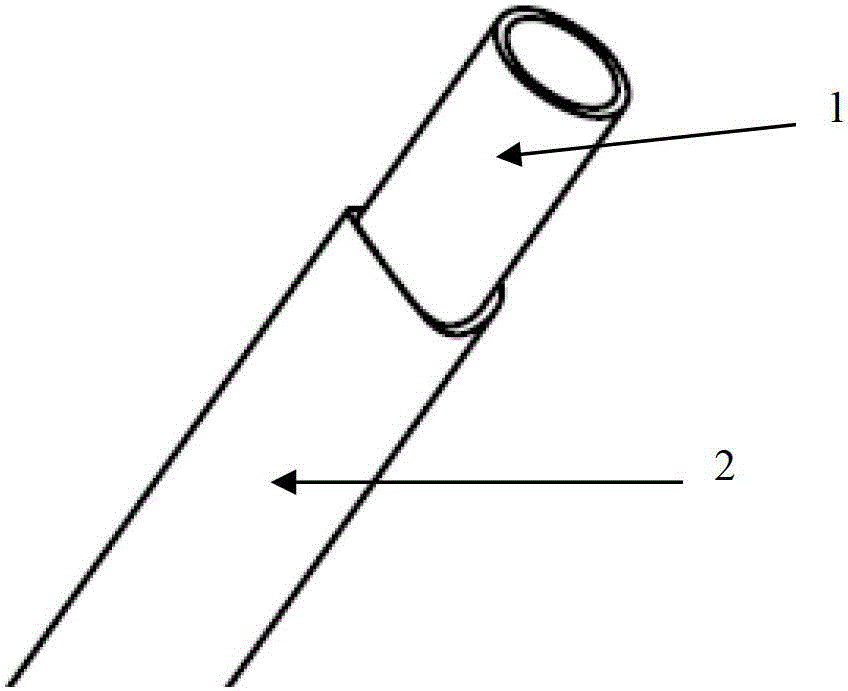

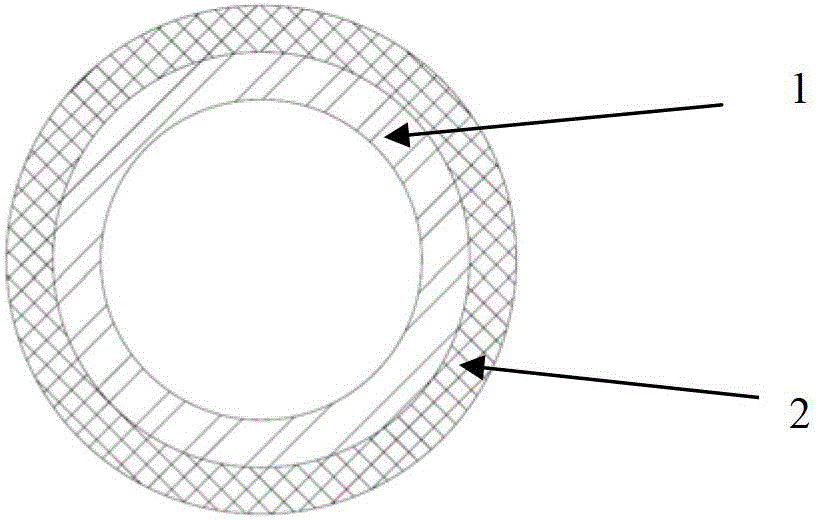

[0021] like figure 1 and 2 As shown, the embodiment of the heat-resistant polyethylene composite pipe is provided with an inner pipe 1 and an outer pipe 2, the inner pipe 1 is a heat-resistant polyethylene (PE-RT) pipe, and the outer pipe 2 is a cross-linked modified Heat-resistant polyethylene (PE-RT) pipe, the outer pipe 2 wraps the inner pipe 1 outside.

[0022] The thickness of the inner tube 1 is 0.5-2.0 mm, and the thickness of the outer tube 2 is 1.0-2.0 mm.

[0023] The preparation method of the heat-resistant polyethylene composite pipe is as follows:

[0024] Through secondary extrusion coating, the inner tube 1 is extruded first, and then another extruder is used to coat the heat-resistant polyethylene (PE-RT) material with a crosslinking agent on the inner tube 1 , to form a cross-linked modified outer pipe 2, so that the inner pipe 1 and the outer pipe 2 ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com