Self-sealing connection type super-aerophobic immersed phase-change liquid-cooling reinforced heat dissipation plate, preparation method and application thereof

A self-adhesive heat dissipation plate technology, which is applied in liquid cooling for modification, cooling/ventilation/heating modification, modification through conduction heat transfer, etc., can solve the problem of contact thermal resistance of heat-generating devices that has not been paid attention to, and the actual processing area is limited. Limitation, lack of structure and shape, etc., to achieve good application prospects, convenient loading and unloading, and fast heat transfer and uniform temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

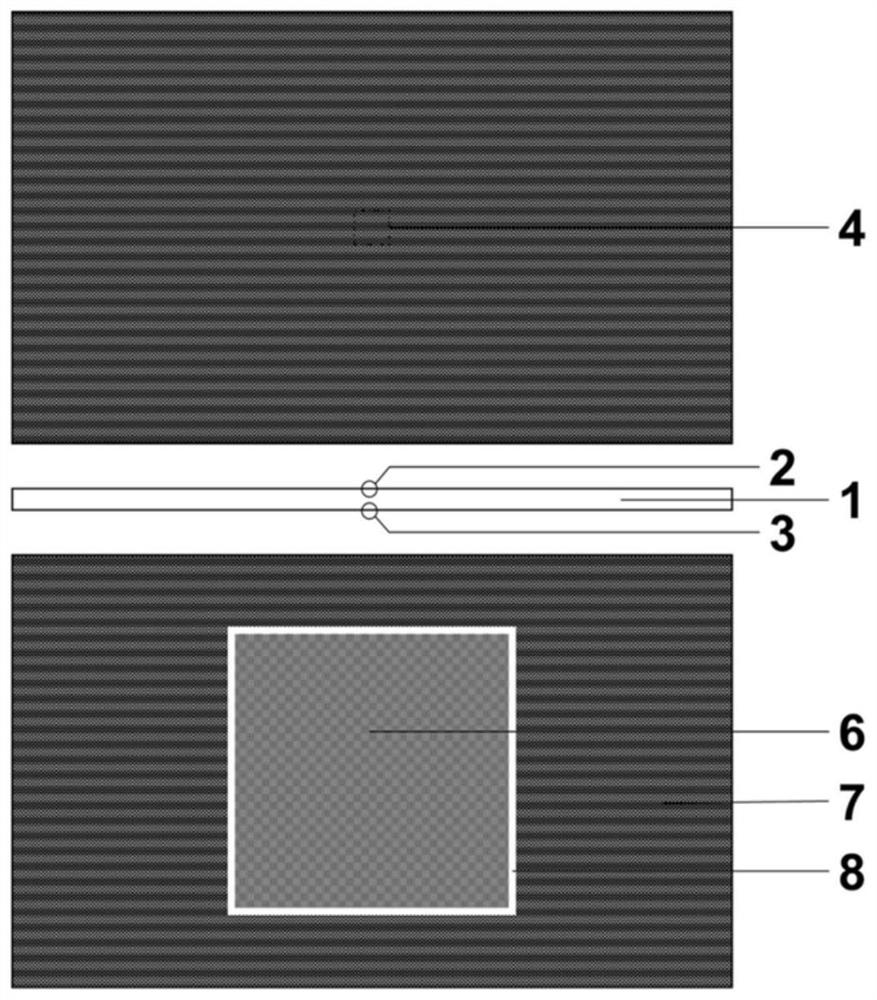

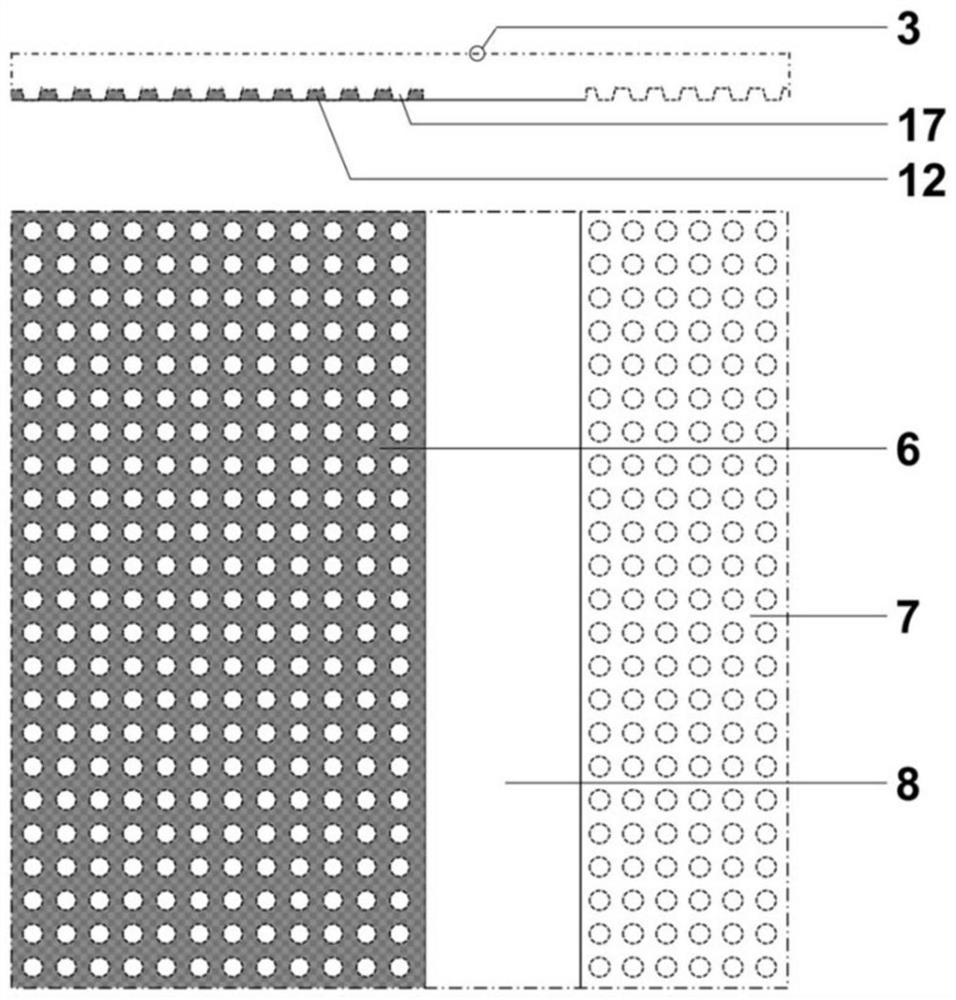

[0062] A self-adhesive super-air-repellent immersion type phase-change liquid-cooled enhanced heat dissipation plate, the surface of the enhanced heat dissipation plate includes a first area and a second area; the surface of the enhanced heat dissipation plate in the first area is distributed with micron papillae arrays, and the surface of the second area is Micron papillae arrays are distributed on the surface of the strengthened heat dissipation plate, and liquid metal is packaged in the gaps between the micron papillae arrays; wherein, the contact area between the strengthened heat dissipation plate and the heating device includes the second area. Among them, the large-area micro-nano composite super-gas-repellent enhanced boiling structure in the first region, and the liquid metal in the second region can self-fill the gap with the heat-generating device, which has high thermal conductivity. Such as Figure 1 ~ Figure 3 As shown, the specific scheme is as follows:

[0063...

Embodiment 2

[0069] A self-adhesive super-air-repellent submerged phase-change liquid-cooled enhanced heat dissipation plate product that meets the actual needs of integrated circuits. The specific plan is as follows:

[0070] Solid red copper reinforced heat dissipation plate formed by cutting, stamping, grinding and polishing, such as Figure 4 As shown, the basic appearance is a flat plate 13 with a size of 120mm×78mm×2mm, and the additional appearance includes a centered bottom surface of 40mm×40mm×8mm prism 14, a centered side wing of 55mm×9mm×8mm fastening belt 15, and reserved screw holes with a diameter of 7mm at specific positions 16. Micromastoid arrays are integratedly etched by laser, and micromastoid arrays are distributed on the upper and lower surfaces of the plate 13, the surrounding and bottom surfaces of the prism 14, and the upper and lower surfaces and sides of the fastening belt 15; wherein, the prism The second area of the bottom surface of 14 has an area of 38mm...

Embodiment 3

[0073] A self-adhesive super-air-repellent immersion type phase-change liquid-cooled enhanced heat dissipation plate product, in addition to using 3D printing, injection and welding processes to form a "heat pipe" type copper vapor chamber in the molding stage, its basic appearance, size parameters and Subsequent preparation methods are consistent with Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com