Installation and construction method of steel reinforced concrete column and steel beam connection joint area

A technology for connecting nodes and concrete columns, which is applied in the field of installation and construction in the connection node area between steel concrete columns and steel beams, can solve the problems that the formwork cannot be reinforced, the workload of stirrup welding increases, and the length of the cantilever is large, etc. Pouring phenomenon, reduced welding workload, and reduced damage to steel structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

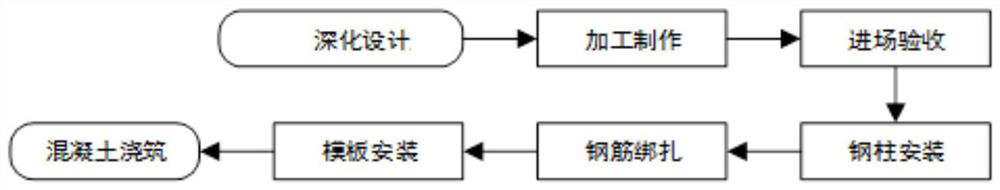

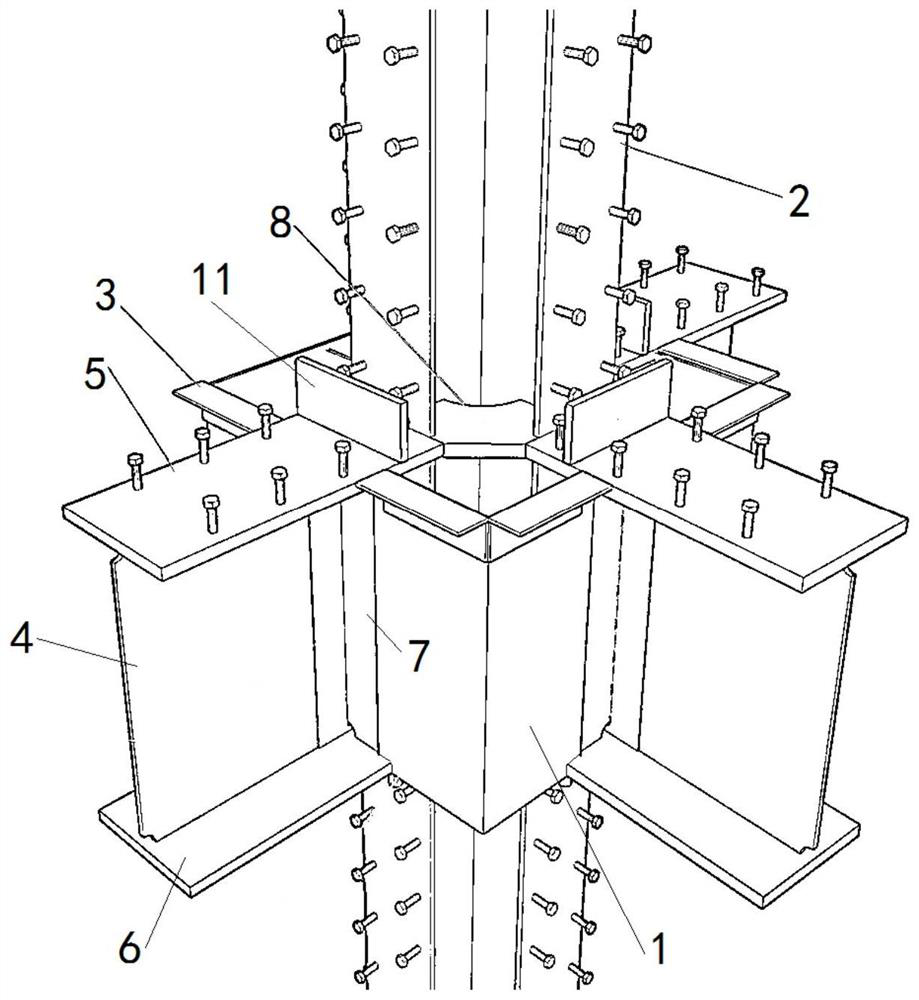

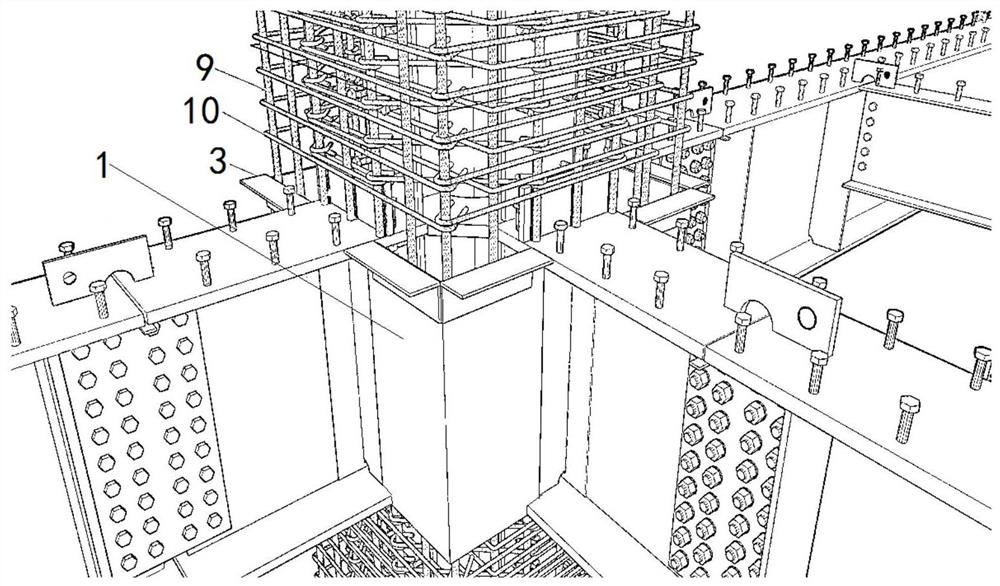

[0033] Such as Figure 1-3 As shown, a method for installation and construction of a joint area between a steel concrete column and a steel beam includes the following steps:

[0034] S1. In-depth design: optimize the connection node area between the steel column and the steel beam, use the steel structure hoarding 1 to replace the original stirrup, carry out typesetting and force calculation on the steel structure hoarding 1, and confirm the size of the steel structure hoarding 1 , position and elevation to form a steel structure deepening diagram; wherein, the yield strength of the steel structure hoarding 1 is greater than that of the steel column 2, and the cross-sectional area of the steel structure hoarding 1 is calculated by equal strength replacement, and the steel structure hoarding 1 The thickness is greater than the diameter of the original stirrup. The steel structure hoarding 1 is designed to meet the requirements of the seismic grade, and the original stirrups...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com