High-quality steel for straight weather-resistant high-strength bolt and production method of high-quality steel

A technology of high-strength bolts and production methods, applied in the field of metallurgy, can solve the problems of steel subcutaneous inclusions, bolt cracks, etc., and achieve the effects of preventing surface cracks, improving impact value, and refining grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

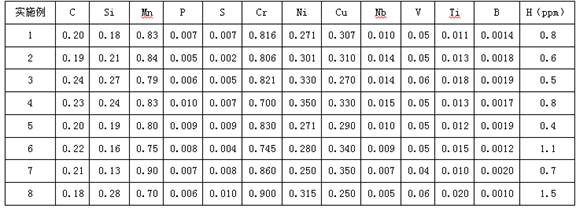

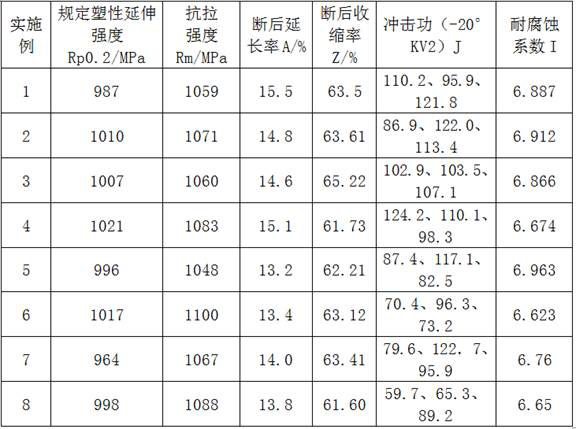

[0023] The specification of fine steel for straight weather-resistant high-strength bolts in this embodiment is φ24mm, and its chemical composition and mass percentage are shown in Table 1.

[0024] The production method of high-quality steel for straight weather-resistant high-strength bolts in this embodiment includes the selection and treatment of raw materials, smelting, pouring, forging, and rolling processes. The specific process steps are as follows:

[0025] (1) Selection of raw materials and processing procedures: select pure iron with a grade of Fe99.5% as the main raw material, and add ferrosilicon, ferrochrome, and ferro-vanadium alloys to the alloys added during the smelting process after baking to 200°C;

[0026] (2) Smelting process: use a vacuum induction furnace to smelt, clean up the residue of the vacuum induction furnace crucible, add pure iron, check the airtightness of the vacuum furnace body, evacuate to 10Pa, send electricity to smelt and keep the vacuum...

Embodiment 2

[0032] The specification of fine steel for straight weather-resistant high-strength bolts in this embodiment is φ20mm, and its chemical composition and mass percentage are shown in Table 1.

[0033] The production method of high-quality steel for straight weather-resistant high-strength bolts in this embodiment includes the selection and treatment of raw materials, smelting, pouring, forging, and rolling processes. The specific process steps are as follows:

[0034] (1) Selection of raw materials and processing procedures: select pure iron containing Fe99.9% as the main raw material, and add ferrosilicon, ferrochrome, and ferro-vanadium alloys to the alloys added during the smelting process after baking to 270°C;

[0035] (2) Smelting process: use a vacuum induction furnace to smelt, clean up the residue of the vacuum induction furnace crucible, add pure iron, check the airtightness of the vacuum furnace body, evacuate to 10Pa, send electricity to smelt and keep the vacuum degr...

Embodiment 3

[0041] The specification of fine steel for straight weather-resistant high-strength bolts in this embodiment is φ27mm, and its chemical composition and mass percentage are shown in Table 1.

[0042] The production method of high-quality steel for straight weather-resistant high-strength bolts in this embodiment includes the selection and treatment of raw materials, smelting, pouring, forging, and rolling processes. The specific process steps are as follows:

[0043] (1) Selection of raw materials and processing procedures: select pure iron with a grade of Fe99.7% as the main raw material, and add ferrosilicon, ferrochrome, and ferrovanadium alloys to the alloys added during the smelting process after baking to 165°C;

[0044] (2) Smelting process: use a vacuum induction furnace to smelt, clean up the residue of the vacuum induction furnace crucible, add pure iron, check the airtightness of the vacuum furnace body, evacuate to 10Pa, send electricity to smelt and keep the vacuum ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com