High-hardness stainless steel as well as preparation method and application thereof

A technology of stainless steel and high hardness, applied in the field of stainless steel materials, can solve the problems of low hardness and achieve the effects of improving mechanical properties, improving segregation, improving wear resistance and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

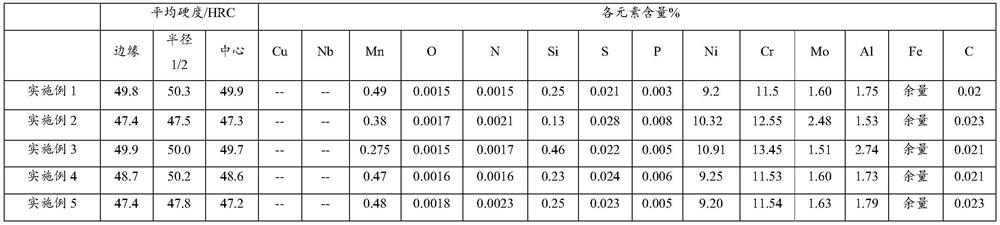

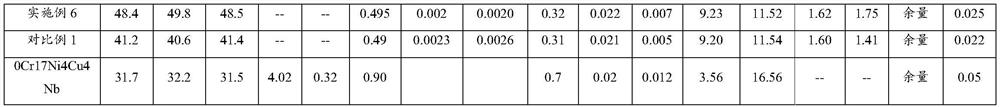

Examples

Embodiment 1

[0035] The present embodiment provides a kind of high hardness stainless steel, and its preparation method is as follows:

[0036] (1) Vacuum induction melting: dosing according to the chemical composition requirements of high hardness stainless steel (calculate the amount of each raw material added); melt each raw material at 1500-1510°C, and then refine at 1550-1560°C, 1-5Pa for 60min ; Then carry out sampling and analysis of all elements, according to the requirements of the components in high-hardness stainless steel, add raw materials according to the analysis results, adjust the components, so that the content of each element reaches the range required by the components in high-hardness stainless steel. Melted in a vacuum induction furnace to form mold steel molten steel for plastics;

[0037] (2) Pouring: pour the plastic mold steel molten steel prepared in step (1) at 1540-1550°C at a pouring speed of 300kg / min into a plastic mold steel electrode billet (250mm in diame...

Embodiment 2

[0043] The present embodiment provides a kind of high hardness stainless steel, and its preparation method is as follows:

[0044](1) Vacuum induction melting: dosing according to the chemical composition requirements of high hardness stainless steel (calculate the amount of each raw material added); melt each raw material at 1520-1530°C, and then refine at 1560-1570°C and 1-5Pa for 120min ; Then carry out sampling and analysis of all elements, according to the requirements of the components in high-hardness stainless steel, add raw materials according to the analysis results, adjust the components, so that the content of each element reaches the range required by the components in high-hardness stainless steel. Melted in a vacuum induction furnace to form mold steel molten steel for plastics;

[0045] (2) Pouring: pour the plastic mold steel molten steel prepared in step (1) at 1550-1560°C at a pouring speed of 200kg / min into a plastic mold steel electrode billet (250mm in di...

Embodiment 3

[0051] The present embodiment provides a kind of high hardness stainless steel, and its preparation method is as follows:

[0052] (1) Vacuum induction melting: dosing according to the chemical composition requirements of high hardness stainless steel (calculate the amount of each raw material added); melt each raw material at 1540-1550°C, and then refine at 1580-1590°C and 1-5Pa for 90min ; Then carry out sampling and analysis of all elements, according to the requirements of the components in high-hardness stainless steel, add raw materials according to the analysis results, adjust the components, so that the content of each element reaches the range required by the components in high-hardness stainless steel. Melted in a vacuum induction furnace to form mold steel molten steel for plastics;

[0053] (2) Pouring: pour the plastic mold steel molten steel prepared in step (1) at 1530-1540°C at a pouring speed of 260kg / min into a plastic mold steel electrode billet (250mm in di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com