Preparation method of flexible regenerated carbon fiber cellulose-based electromagnetic shielding film and product thereof

An electromagnetic shielding, cellulose-based technology, applied in the field of preparation of cellulose-based electromagnetic shielding films, can solve the problems of low absorption effect of electromagnetic shielding materials, electromagnetic wave radiation pollution, high density, etc., and achieves improved electromagnetic shielding efficiency and flexibility. Effect of inner specific surface area and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

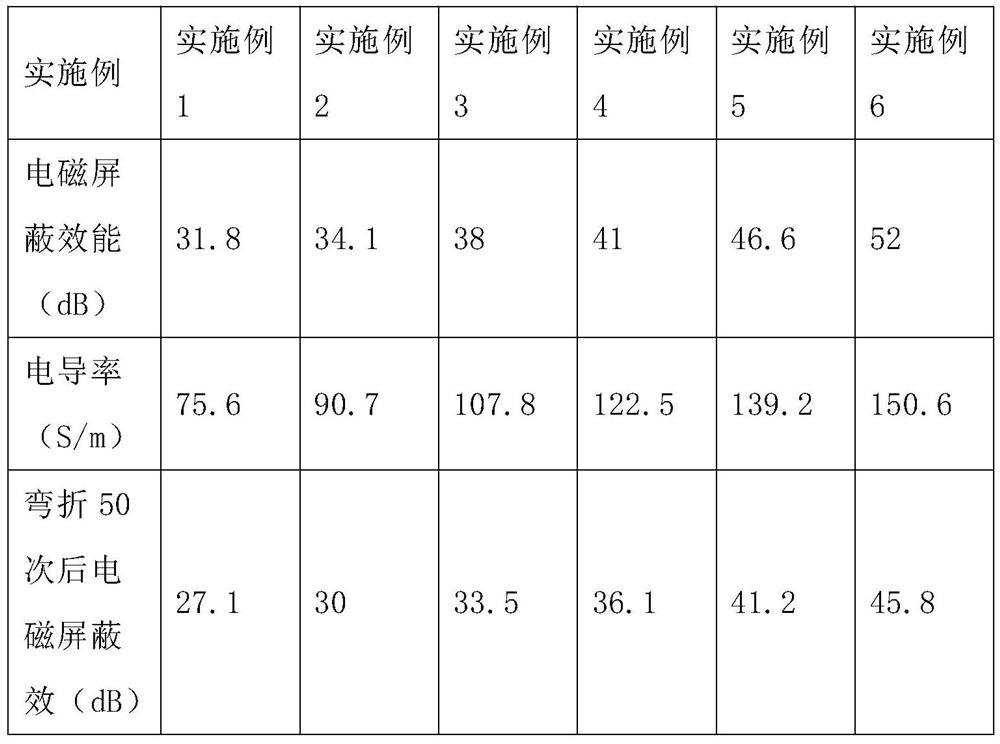

Examples

Embodiment 1

[0065] Weigh 0.02 mol Tris, deionized water was added, dissolved in the flask, to give 20mmol / L of Tris solution, was added dropwise concentrated hydrochloric acid number pH is adjusted to about 8.5; Tris buffer solution prepared using a solution concentration of dopamine 4mg / mL after taken out, at room temperature regenerated chopped carbon fibers immersed 30h dopamine solution. Washed with deionized water repeatedly until the filtrate was clear, colorless; after centrifugation placed in a vacuum oven, the oven temperature 70 ℃, drying time 24h. Regenerated carbon fiber surface modification treatment of dopamine.

[0066] Weigh 4mmol ferric nitrate dissolved in 50mL ethanol solution, referred to as a first solution. Weigh 2.4g of polyvinylpyrrolidone (PVP, K30), 0.7g trimesic acid, dopamine recycled carbon fiber modification, was dissolved in 50mL ethanol solution, referred to as the second solution. The first and second solutions were mixed and stirred uniformly after a clea...

Embodiment 2

[0070] Weigh 0.02 mol Tris, deionized water was added, dissolved in the flask, to give 20mmol / L of Tris solution, was added dropwise concentrated hydrochloric acid number pH is adjusted to about 8.5; Tris buffer solution prepared using a solution concentration of dopamine 4mg / mL after taken out, at room temperature regenerated chopped carbon fibers immersed 30h dopamine solution. Washed with deionized water repeatedly until the filtrate was clear, colorless; after centrifugation placed in a vacuum oven, the oven temperature 70 ℃, drying time 24h. Regenerated carbon fiber surface modification treatment of dopamine.

[0071] Weigh 4mmol ferric nitrate dissolved in 50mL ethanol solution, referred to as a first solution. Weigh 2.4g of polyvinylpyrrolidone (PVP, K30), 0.7g trimesic acid, dopamine recycled carbon fiber modification, was dissolved in 50mL ethanol solution, referred to as the second solution. The first and second solutions were mixed and stirred uniformly after a clea...

Embodiment 3

[0076] Weigh 0.02 mol Tris, deionized water was added, dissolved in the flask, to give 20mmol / L of Tris solution, was added dropwise concentrated hydrochloric acid number pH is adjusted to about 8.5; Tris buffer solution prepared using a solution concentration of dopamine 4mg / mL after taken out, at room temperature regenerated chopped carbon fibers immersed 30h dopamine solution. Washed with deionized water repeatedly until the filtrate was clear, colorless; after centrifugation placed in a vacuum oven, the oven temperature 70 ℃, drying time 24h. Regenerated carbon fiber surface modification treatment of dopamine.

[0077] Weigh 4mmol ferric nitrate dissolved in 50mL ethanol solution, referred to as a first solution. Weigh 2.4g of polyvinylpyrrolidone (PVP, K30), 0.7g trimesic acid, dopamine recycled carbon fiber modification, was dissolved in 50mL ethanol solution, referred to as the second solution. The first and second solutions were mixed and stirred uniformly after a clea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com