Automobile bumper using gradient foamed aluminum

A technology of automobile bumper and aluminum foam, applied in the direction of bumper, etc., can solve the problems of poor collision ability and low strength of pure foam aluminum, and achieve the effect of improving anti-collision performance, high strength and strong energy absorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

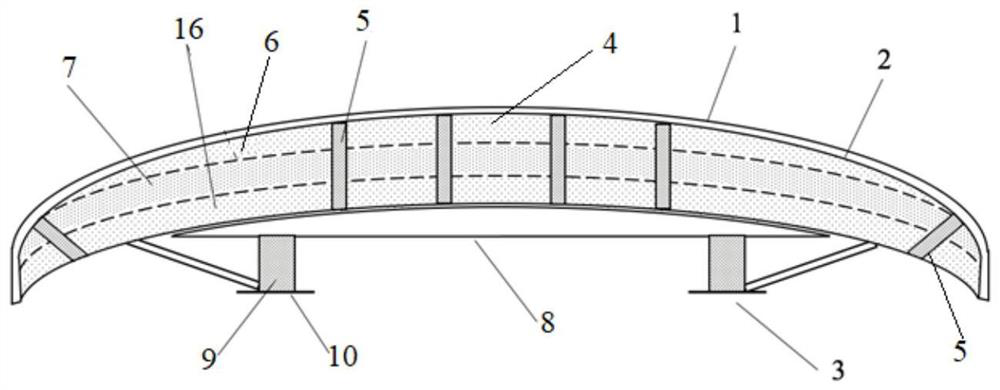

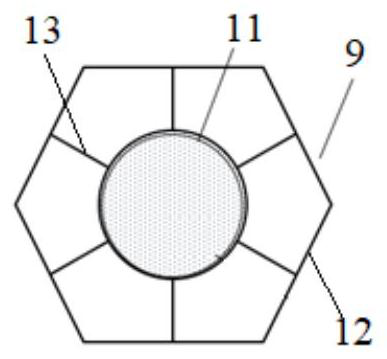

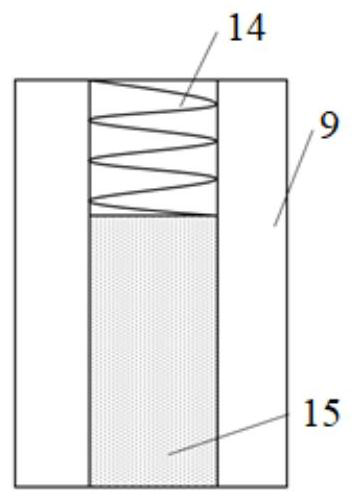

[0051] A car bumper using gradient aluminum foam, such as figure 1 As shown, it includes a bumper shell 1 made of plastic, a buffer energy-absorbing layer 2 and a bumper frame 3 , and the buffer energy-absorbing layer 2 is fixedly connected to the bumper shell 1 and the bumper frame 3 respectively. The buffer energy-absorbing layer 2 includes a composition gradient composite foam material layer 4 and a density gradient aluminum foam filling tube 5. The composition gradient composite foam material layer is made by adding a pore-forming agent by powder metallurgy, and consists of an outer aluminum foam block 6 and an inner foam aluminum block. 16 and the middle carbon nanotube reinforced aluminum foam matrix composite material 7, the inner and outer aluminum foam density is 1.08g / cm 3 , the corresponding porosity is 60%, the carbon nanotube mass fraction of the intermediate carbon nanotube reinforced aluminum foam matrix composite material is 2.5wt.%, and the porosity is the sam...

Embodiment 2

[0055] In this embodiment, the buffer energy-absorbing layer includes a functional gradient composite foam material layer and a density gradient aluminum foam filling pipe. The composition gradient composite foam material layer is made by adding a pore-forming agent by powder metallurgy, and consists of an outer aluminum foam block and an inner foam aluminum block. It is composed of carbon nanotube reinforced aluminum foam matrix composite material in the middle, and the density of aluminum foam on the outside and inside is 0.54g / cm 3, the corresponding porosity is 80%, the mass fraction of carbon nanotubes in the carbon nanotube reinforced aluminum foam matrix composite material is 2wt.%, and the porosity is 60%. The density gradient aluminum foam filling tube is made of 4 layers of density gradient aluminum foam with a porosity of 40-80% in situ filling an aluminum alloy thin-walled tube with a wall thickness of 1.5mm. The density gradually increases towards the direction of ...

Embodiment 3

[0058] In this embodiment, the buffer energy-absorbing layer includes a functional gradient composite foam material layer and a density gradient aluminum foam filling pipe. One layer of carbon nanotube reinforced aluminum foam matrix composite material and two inner layers of foamed aluminum blocks; along the direction close to the body, the density of the outer two layers of foamed aluminum is 0.54g / cm 3 , 1.08g / cm 3 , the corresponding porosity is 80% and 60%, respectively, the mass fraction of carbon nanotubes in the three-layer carbon nanotube reinforced aluminum foam matrix composite material is 2wt.%, the porosity is 60%, 40%, 60%, respectively, and the inner two layers The density of aluminum foam is 1.08g / cm 3 , 0.54g / cm 3 , corresponding to porosity of 60% and 80%, respectively. The density gradient aluminum foam filling tube is made of 4 layers of density gradient aluminum foam with a porosity of 40-80% in situ filling an aluminum alloy thin-walled tube with a wal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com