Preparation process of machining high-strength refractory materials

A refractory material and high-strength technology, applied in the field of refractory materials, can solve problems such as thermal fatigue loss of peripheral equipment components, reduce the safety of equipment processing life, and reduce the time for raw materials to heat up, so as to save raw materials, reduce losses, and improve efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

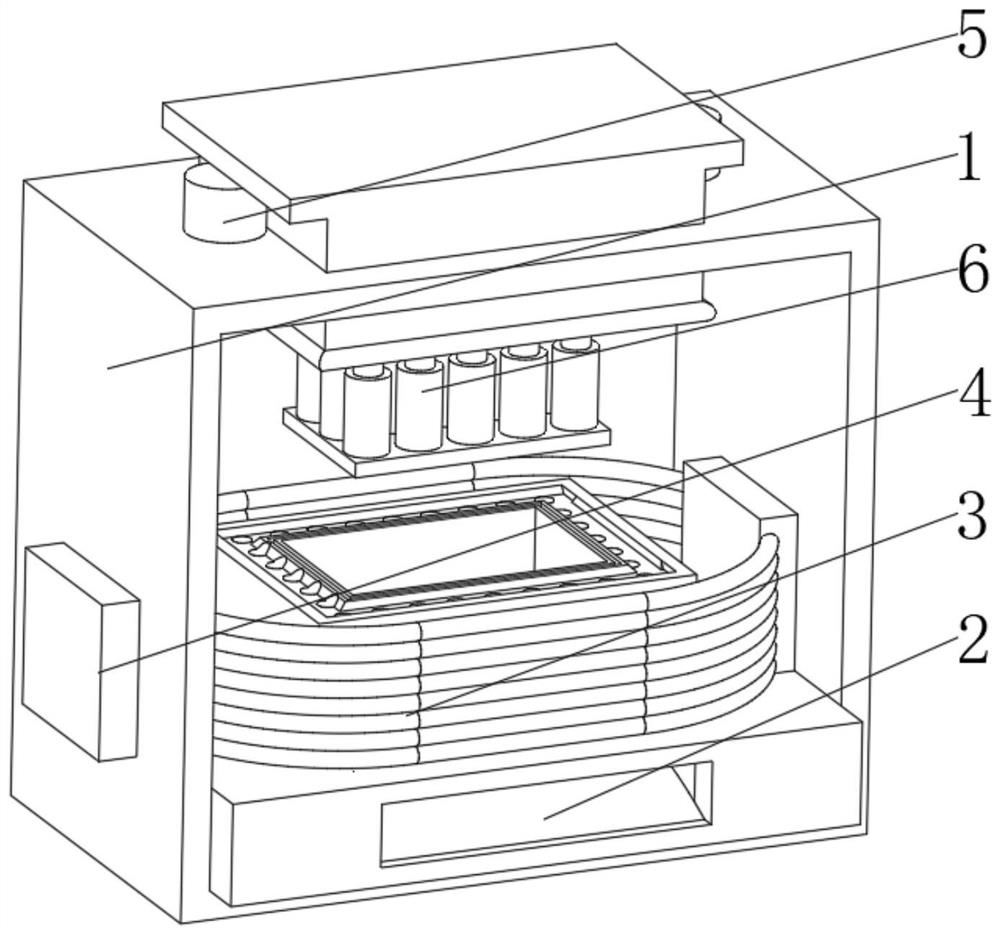

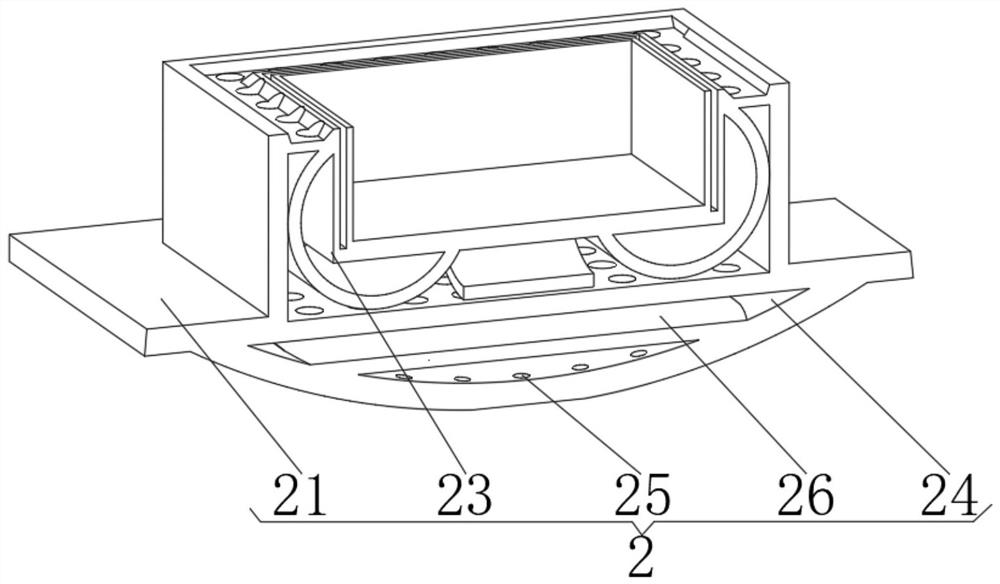

[0043] see Figure 1-6 , the present invention provides a technical solution: a machined high-strength refractory material preparation device, specifically comprising:

[0044] A protective box 1, the protective box 1 has a square box body, and a heat setting device 2 installed at the bottom of the inner cavity of the square box, and an eddy current coil 3 installed on the top of the outer surface of the heat setting device 2, and installed on both sides of the eddy current coil 3 The current converter 4, and the electric lifting column 5 installed on the top of the square box, and the pressing device 6 installed on the top of the electric lifting column 5, through the setting of the eddy current coil 3, the heat setting device 2 is subjected to high-frequency induction heating, Effectively increase the heating speed of the raw materials prepared inside the heat setting device 2, save time and improve efficiency, and at the same time, the setting of the eddy current coil 3 wil...

Embodiment 2

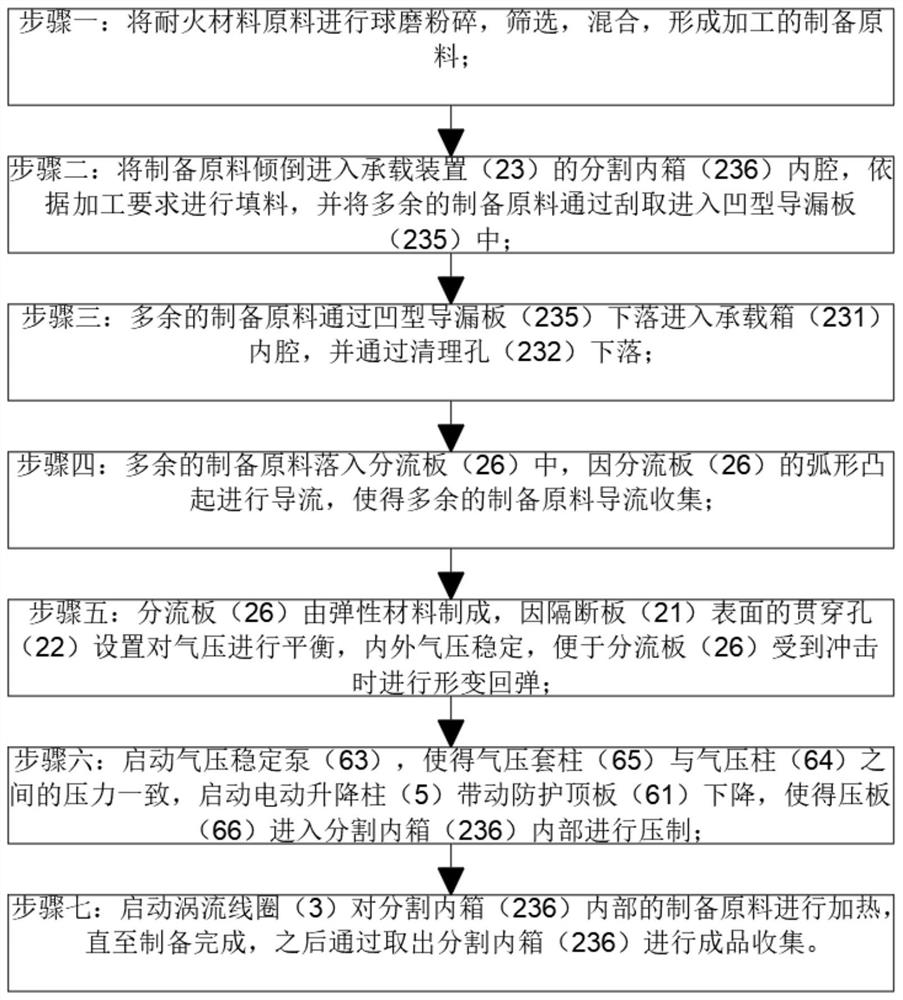

[0054] see Figure 1-6 On the basis of Embodiment 1, the present invention provides a technical solution: a process for preparing a machined high-strength refractory material, comprising the following steps,

[0055] Step 1: ball milling, screening and mixing the refractory material raw materials to form the raw materials for processing;

[0056] Step 2: Pour the prepared raw materials into the cavity of the divided inner box 236 of the carrying device 23, fill according to the processing requirements, and scrape the excess prepared raw materials into the concave leak guide plate 235;

[0057] Step 3: The redundant preparation raw materials fall into the inner cavity of the bearing box 231 through the concave leak guide plate 235, and fall through the cleaning hole 232;

[0058] Step 4: The redundant preparation raw materials fall into the splitter plate 26, and the arc-shaped protrusions of the splitter plate 26 conduct flow diversion, so that the redundant preparation raw m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com