A kind of preparation method of micro-nano zinc capable of killing bacteria and inactivating viruses

A technology of inactivation and virus, applied in the field of nano antibacterial, can solve the problems of high price, non-metabolism, easy discoloration, etc., and achieve the effect of low cost, not easy to reunite, and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

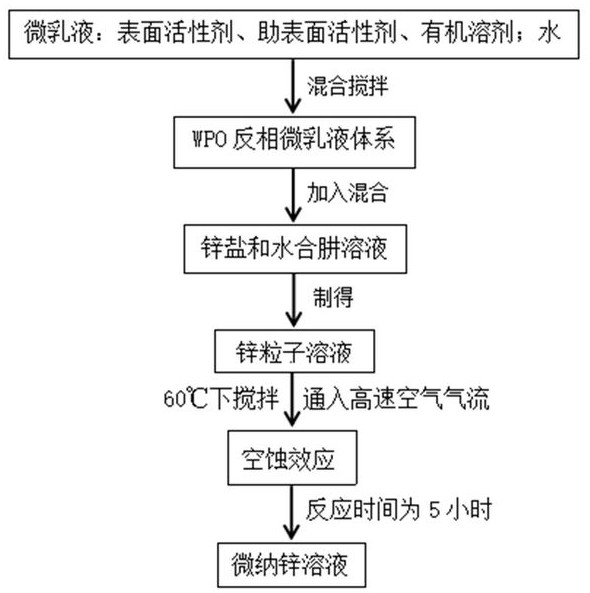

[0038] Such as figure 1 The flow chart of the steps shown, a method for preparing micro-nano zinc capable of killing bacteria and inactivating viruses, comprises the following steps:

[0039] Step 1.1: Dissolve 50 mL of nonylphenol polyoxyethylene ether and 30 mL of n-octanol in 120 mL of cyclohexane, and stir with 20 mL of isoamyl alcohol and 200 mL of deionized water to prepare a WPO reverse microemulsion system;

[0040] Step 1.2: Add 1000mL of a mixture of zinc citrate and zinc nitrate with a concentration of 450g / L and 1000mL of hydrazine hydrate solution into 3600mL of WPO inverse microemulsion, mix them, and react at 65°C and 4600rpm for 6.5h to obtain the particle size Zinc particle solution at 10nm-600nm;

[0041] Step 2.1: Transfer the prepared zinc particle solution to the next reaction kettle, stir at 60°C and 4600rpm, and at the same time introduce high-speed air flow to form cavitation phenomenon;

[0042] Step 2.2: The reaction time is 5 hours to prepare a mic...

Embodiment 2

[0047] The micro-nano zinc solution prepared in Example 1 was configured into a micro-nano zinc aqueous solution with a concentration of 1000 mg / kg, and then diluted successively to concentrations of: 800 mg / kg, 500 mg / kg, 400 mg / kg, and 300 mg / kg. Micro-nano zinc aqueous solution, the micro-nano zinc aqueous solution with a concentration of 1000 mg / kg, 800 mg / kg, 500 mg / kg, 400 mg / kg, and 300 mg / kg is marked as group 5, group 4, group 3, group 2, group 1. Determine the bactericidal rate of the micro-nano zinc aqueous solution according to the "Disinfection Technical Specifications" suspension quantitative method, the test bacteria are Escherichia coli, Staphylococcus aureus, Candida albicans, Pseudomonas aeruginosa, and the test time is 20s, 30s, 60s respectively ; Test result is as shown in table 1, and the micronano zinc aqueous solution of group 1 to group 5 different concentrations is to escherichia coli, Staphylococcus aureus, Candida albicans, Pseudomonas aeruginosa effe...

Embodiment 3

[0050] The micro-nano zinc solution prepared in Example 1 was configured into a micro-nano zinc aqueous solution with a concentration of 1000 mg / kg, and then diluted successively to concentrations of: 800 mg / kg, 500 mg / kg, 400 mg / kg, and 300 mg / kg. Micro-nano zinc aqueous solution, the micro-nano zinc aqueous solution with a concentration of 1000 mg / kg, 800 mg / kg, 500 mg / kg, 400 mg / kg, and 300 mg / kg is marked as group 5, group 4, group 3, group 2, group 1. Determine the virus inactivation rate of the micro-nano zinc aqueous solution according to the "Disinfection Technical Specifications". The tested viruses are poliovirus, influenza A virus H1N1, enterovirus, and avian influenza virus H5N1. The test time is 10s, 20s, 30s; the test results are shown in Table 2.

[0051]

[0052] Dilute the commercially available 3% hydrogen peroxide disinfectant, and dilute in turn into hydrogen peroxide aqueous solutions with concentrations of 1000mg / kg, 800mg / kg, 500mg / kg, 400 mg / kg, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com