High-strength high-toughness TiZrHfNbTaWx refractory high-entropy alloy and preparation method thereof

A high-entropy alloy, high-toughness technology, applied in the field of material processing, can solve the problems of cumbersome powder metallurgy preparation procedures, large alloy voids, low sintering temperature, etc., and achieves excellent high-temperature mechanical application prospects, uniform metallographic structure, and simple operation methods. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

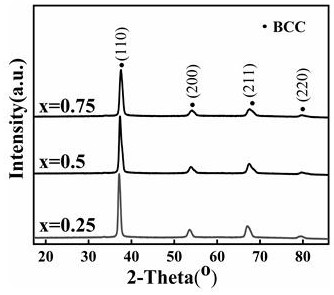

[0033] This embodiment is a high-strength and high-toughness TiZrHfNbTaW x (x=0.25,0.5,0.75) The refractory high-entropy alloy is composed of Ti, Zr, Hf, Nb, Ta, W elements, and the molar ratio of Ti, Zr, Hf, Nb, Ta, W elements is 1 / (x +5):1 / (x+5):1 / (x+5):1 / (x+5):1 / (x+5):x / (x+5). For the preparation raw materials of this alloy, pure Ti, pure Zr, pure Hf, pure Nb, pure Ta, pure W are selected, and the specific quality of each material is shown in the table below:

[0034] Table 1 Ratio of Raw Materials

[0035]

[0036] The specific implementation process is as follows:

[0037] A High Strength and High Toughness TiZrHfNbTaW x (x=0.25,0.5,0.75) the preparation method of refractory high-entropy alloy comprises the following steps:

[0038] Step 1, pre-treatment: use a grinder to polish the surface scales of pure Ti, pure Zr, pure Hf, pure Nb, pure Ta, and pure W with a purity ≥ 99.95%, and then put them into a container filled with absolute ethanol In the beaker, use ult...

Embodiment 2

[0055] Embodiment 2: After calculating TiZrHfNbTaW x (x=0.25,0.5,0.75) Refractory high-entropy alloy (RHEA) related parameters mixing melting point Tm, mixing entropy △Smix, mixing enthalpy △Hmix, atomic size difference δ, parameter Ω, valence electron concentration VEC, electronegativity difference Δχ is summarized in Table 2. For BCC refractory high-entropy alloys, the atomic size difference δ, mixing enthalpy △Hmix, valence electron concentration VEC, and Ω criteria are more meaningful. When Ω≥1.1, δ≤6.6, the alloy tends to form a solid solution. However, Ω=31.8 of TiZrHfNbTaW0.25 refractory high-entropy alloy is much larger than 1.1, and δ=4.242<6.6. Therefore, TiZrHfNbTaW0.25 alloy is a single-phase solid solution, known as a refractory high-entropy alloy.

[0056] Table 2 Calculation table of related parameters of TiZrHfNbTaW0.25 refractory high-entropy alloy

[0057]

[0058] The calculation formulas of relevant parameters are as follows:

[0059]

[0060] ...

Embodiment 3

[0066] Example 3: The instrument used for testing the micro-Vickers hardness of the alloy obtained in step 3 is MH-600 microhardness tester with a load of 500 g and a retention time of 30 s.

[0067] Before the experiment, the sample was treated with 240#, 600#, 800#, 1000#, 1200#, 1500#, 2000#, 3000#, 4000# sandpaper to polish the surface of the sample, and then polished to ensure the sample plane It is flat enough. In order to ensure the accuracy of the experimental results, select different positions for each sample to test 5 times, and finally read the Vickers hardness value of the alloy displayed by the microscope. After the test, the average value of the 5 measurements is taken as the final value. They are summarized in Table 3 below:

[0068] Table 3 Microhardness of TiZrHfNbTaW0.25 refractory high-entropy alloy

[0069]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com