TiC reinforced low-density niobium alloy and structure-controllable laser three-dimensional forming method thereof

A laser three-dimensional forming, niobium alloy technology, applied in the direction of additive processing, process efficiency improvement, additive manufacturing, etc., can solve problems such as less research, achieve obvious technical advantages, excellent comprehensive performance, and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

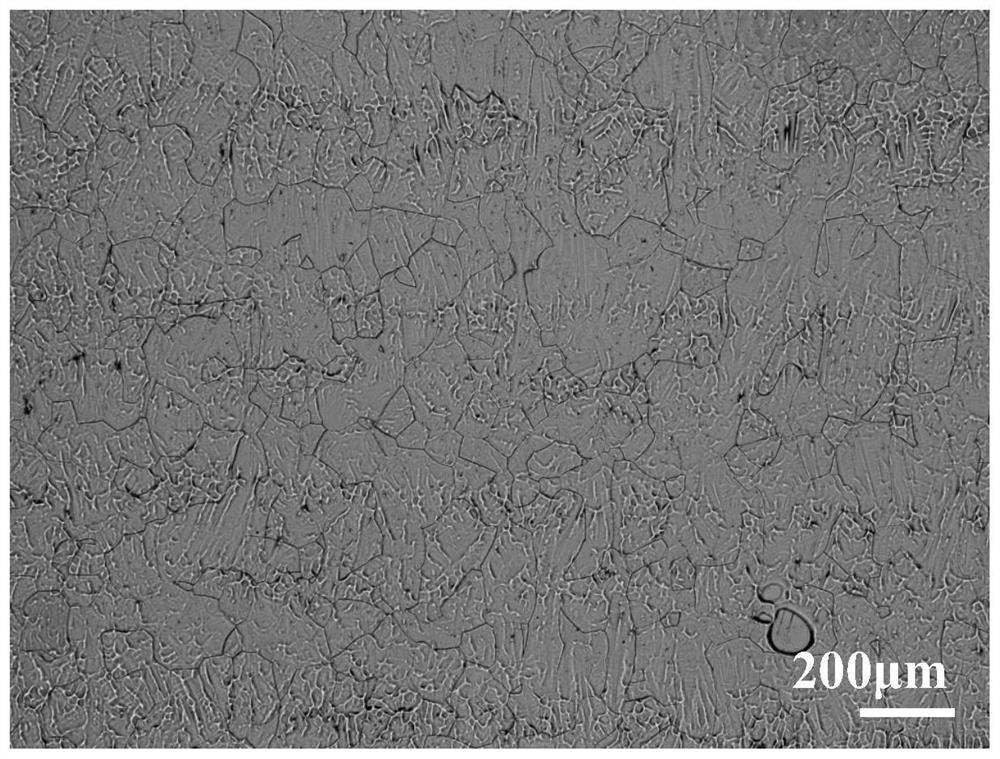

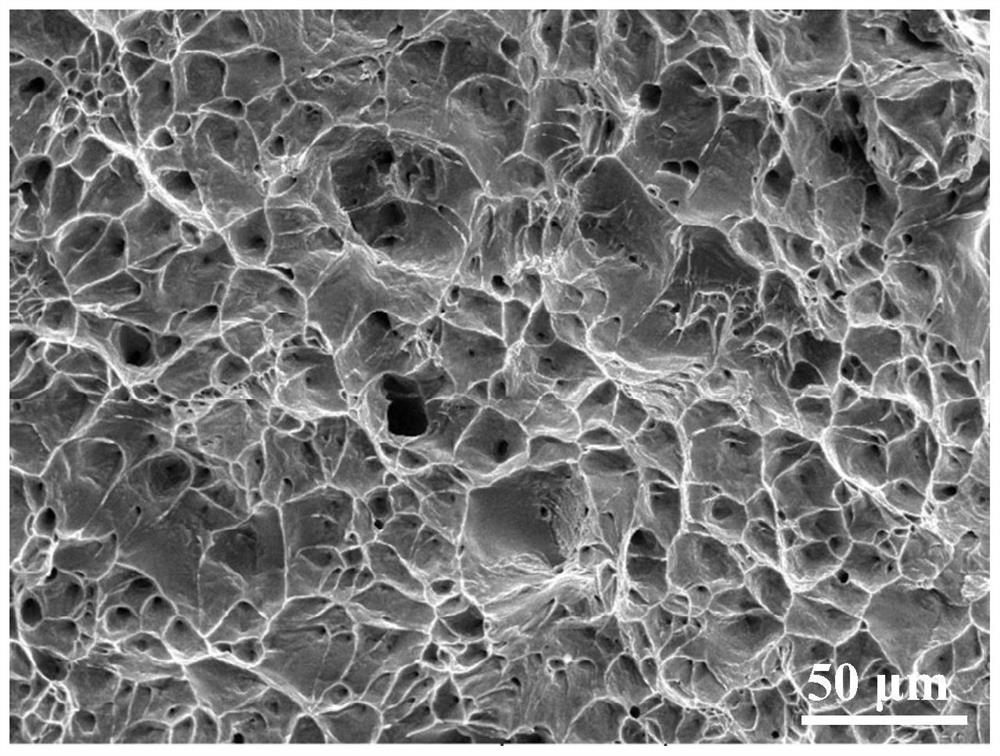

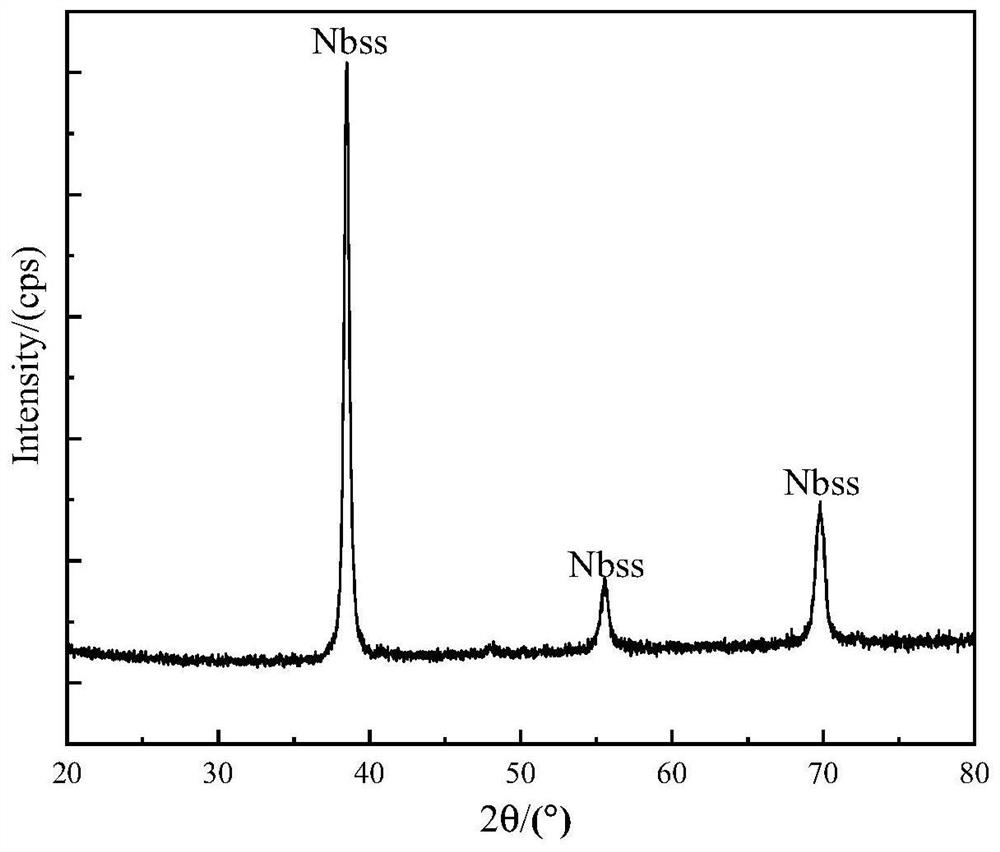

[0035] A microstructure-controllable laser three-dimensional forming method of a low-density niobium alloy. The composition of the low-density niobium alloy in this embodiment is Nb-37Ti-5A1.

[0036] The preparation process of the niobium alloy comprises the following steps:

[0037] Step 1. Spherical niobium powder with a particle size of 75-150 μm and an oxygen content of 0.022wt.%, spherical titanium powder with a particle size of 75-150 μm and an oxygen content of 0.082wt.%, and non- The spherical aluminum powder is mixed evenly to obtain a mixed powder, and the mixed powder is dried for 4 hours in an environment with a temperature of 85° C. and a vacuum degree of 0.08 MPa to obtain a powder to be formed.

[0038] Step 2. Using the powder to be formed as a raw material, a low-density niobium alloy is prepared by laser three-dimensional forming; the process of laser three-dimensional forming is as follows: adopting the method of synchronous powder feeding on a continuous f...

Embodiment 2

[0042] A microstructure-controllable laser three-dimensional forming method of a low-density niobium alloy. The composition of the low-density niobium alloy in this embodiment is Nb-37Ti-5A1.

[0043] The preparation process of the niobium alloy comprises the following steps:

[0044] Step 1, the non-spherical niobium powder with a particle size of 75-150 μm and an oxygen content of 0.23wt.%, the non-spherical titanium powder with a particle size of 75-150 μm and an oxygen content of 0.30wt.%, and the non-spherical titanium powder with a particle size of 75-150 μm The spherical aluminum powder is mixed uniformly to obtain a mixed powder, and the mixed powder is dried for 5 hours in an environment with a temperature of 80° C. and a vacuum degree of 0.08 MPa to obtain a powder to be shaped.

[0045] Step 2. Using the powder to be formed as a raw material, a low-density niobium alloy is prepared by laser three-dimensional forming; the process of laser three-dimensional forming is a...

Embodiment 3

[0050] The invention discloses a microstructure-controllable laser three-dimensional forming method of TiC-enhanced low-density niobium alloy, the alloy composition of which is Nb-37Ti-10Al-3TiC.

[0051] The preparation process includes the following steps:

[0052] Step 1, the non-spherical niobium powder with a particle size of 75-150 μm and an oxygen content of 0.23wt.%, and the non-spherical titanium powder with a particle size of 75-150 μm and an oxygen content of 0.30wt.%; The non-spherical aluminum powder and the non-spherical titanium carbide powder with a particle size of 45-106 μm are uniformly mixed to obtain a mixed powder; the mixed powder is dried for 5 hours in an environment with a temperature of 85° C. and a vacuum degree of 0.08 MPa to obtain a ready-to-form powder.

[0053] Step 2. Using the powder to be formed as a raw material, a low-density niobium alloy is prepared by laser three-dimensional forming; the process of laser three-dimensional forming is as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com