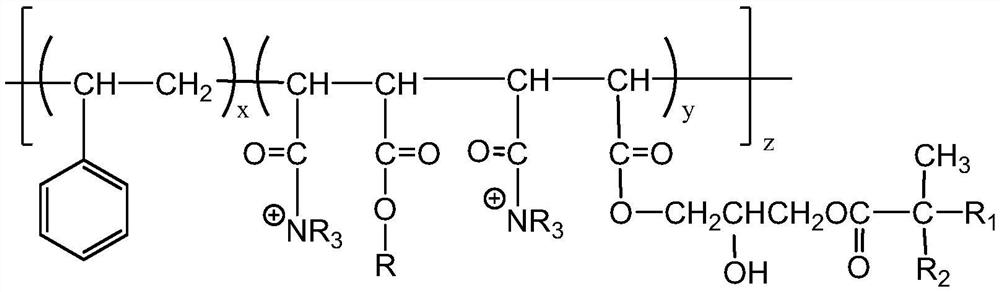

Preparation method and application of comb-shaped benzene-horse polymer aqueous dispersant

A water-based dispersant, polymer technology, applied in chemical instruments and methods, dissolution, pigment slurry, etc., can solve the problems of not being widely applicable, not very firm in adsorption, poor long-term stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

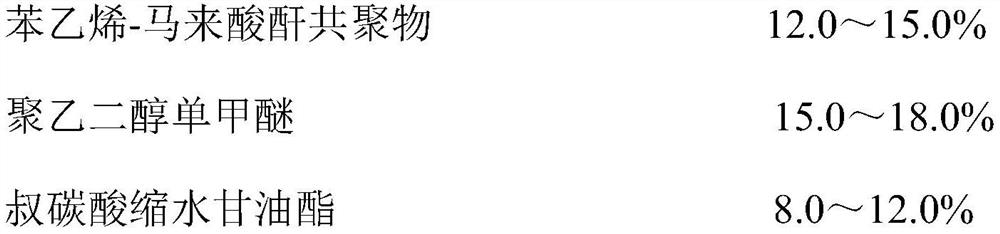

[0038] A kind of comb-shaped benzene-horizon polymer aqueous dispersant, its preparation steps are as follows:

[0039] According to weight percentage, weigh 125.0 parts of SMA1200, 152.0 parts of MPEG1000, and 85.0 parts of glycidyl tertiary carbonic acid ester and add them into the reaction kettle, heat up to 120°C and start to melt, turn on the vacuum, control the vacuum degree to 0.09MPa and dehydrate for 1 hour; After melting, start stirring, continue to heat up to 170-175°C, and control the vacuum degree to 0.07-0.08MPa to react for 4 hours, take samples every 0.5h to detect the acid value, stop the reaction when the acid value reaches the specified value; cool down to 120°C, close N 2, add 2.5 parts of triethylamine under stirring, and add 540.0 parts of deionized water at the same time, when the pH value is 7.2 to 7.5, cool down to 60°C, filter and pack, and obtain a comb-shaped benzene-horse polymer aqueous solution with a solid content of 41.2%. Dispersant.

Embodiment 2

[0041] A kind of comb-shaped benzene-horizon polymer aqueous dispersant, its preparation steps are as follows:

[0042] According to weight percentage, weigh 126.0 parts of SMA1000, 155.0 parts of MPEG1000, and 82.0 parts of glycidyl tertiary carbonic acid ester into the reaction kettle, heat up to 120°C and start to melt, turn on the vacuum, control the vacuum degree to 0.09MPa and dehydrate for 1 hour; wait for complete After melting, start stirring, continue to heat up to 170-172°C, and control the vacuum degree to 0.07-0.08MPa to react for 4 hours, take samples every 0.5h to detect the acid value, stop the reaction when the acid value reaches the specified value; cool down to 120°C, close N 2 , add 2.6 parts of triethylamine under stirring, and add 550.0 parts of deionized water at the same time, when the pH value is 7.0 to 7.2, cool down to 60°C, filter and pack, and obtain a comb-shaped benzene-horse polymer aqueous solution with a solid content of 40.5%. Dispersant.

Embodiment 3

[0044] A kind of comb-shaped benzene-horizon polymer aqueous dispersant, its preparation steps are as follows:

[0045] According to weight percentage, weigh 125.0 parts of SMA1000, 150.0 parts of MPEG1200, and 90.0 parts of glycidyl tertiary carbonic acid ester and add them into the reaction kettle, heat up to 120°C and start to melt, turn on the vacuum, control the vacuum degree to 0.09MPa and dehydrate for 1 hour; wait for complete After melting, start stirring, continue to heat up to 170-172°C, and control the vacuum degree to 0.07-0.08MPa to react for 4 hours, take samples every 0.5h to detect the acid value, stop the reaction when the acid value reaches the specified value; cool down to 120°C, close N 2 , add 3.0 parts of triethanolamine under stirring, and add 550.0 parts of deionized water at the same time, when the pH value is 7.0 to 7.2, cool down to 60°C, filter and pack, and obtain a comb-shaped benzene-horse polymer aqueous dispersion with a solid content of 40.2%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com