Non-ionic polyether type high-molecular surfactant as well as preparation method and application thereof

A non-ionic polyether and surfactant technology, applied in dyeing, textiles and papermaking, etc., can solve the problems of no degreasing and decontamination performance, achieve strong removal, strong adsorption performance, and avoid flocculation and precipitation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

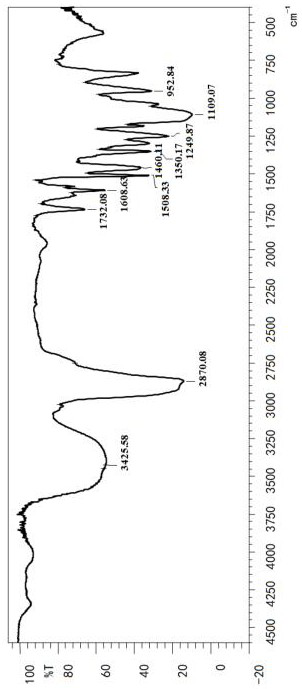

Image

Examples

preparation example Construction

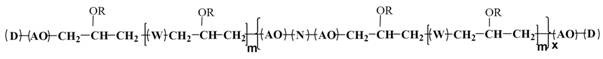

[0055] The preparation method of above-mentioned nonionic polyether type polymer surfactant, comprises the steps:

[0056] A, prepare the compound of following structural formula (1);

[0057] (1)

[0058] (1) Alkoxylation reaction: the above-mentioned monofunctional compound and difunctional compound with a molar ratio of 1:0.5 to 10 and the total mass of the monofunctional compound and the difunctional compound accounted for 0.02 to 1 % catalyst I was added to the reactor, stirred at 70-130°C for 30 minutes, vacuumed to remove water and replaced with nitrogen, so that the water content in the reaction system was lower than 0.1% of the raw material mass, and the oxygen content was lower than 500ppm; then added Quantitative 1,2-epoxyalkylene compound, react at 80~180℃, -0.1~0.6MPa for 0.4~4h, after the reaction is completed, remove non-condensable gas and trace unreacted epoxyalkylene compound, then add acidic Neutralizing agent (such as inorganic acid, organic acid or aci...

Embodiment 1

[0088] Put 150 grams of 3-(8-pentadecenyl)-phenol, 3-(8,11-pentadecadienyl)-phenol, a mixture of 3-pentadecenylphenol (about 0.5 moles), 142 grams of 5-(8-pentadecenyl)-1,3-benzenediol, 5-(8,11-pentadecadienyl)-1,3-benzenediol, 5-pentadecene A mixture of alkyl-1,3-benzenediols (about 0.5 moles), 16.5 g of 2-methyl-5-(8-pentadecenyl)-1,3-benzenediol, 2-methyl- Mixture of 5-(8,11-pentadecadienyl)-1,3-benzenediol, 2-methyl-5-pentadecadienyl-1,3-benzenediol (about 0.05 moles) Put it into a high-pressure reactor, add 4.9 grams of 30% sodium methoxide methanol solution, heat up to 100 ° C for 60 minutes, and take a sample to detect that the moisture in the material is less than 0.1%. Replace nitrogen, and after the oxygen content in the kettle is lower than 500ppm, continue to feed 4950 grams (about 112.5 moles) of ethylene oxide, control the reaction temperature at 155-165°C, complete the introduction of ethylene oxide, keep warm at 120-165°C, and mature 30 minutes, until the pre...

Embodiment 2

[0093] Put 150 grams of 3-(8-pentadecenyl)-phenol, 3-(8,11-pentadecadienyl)-phenol, a mixture of 3-pentadecenylphenol (about 0.5 moles), 142 grams of 5-(8-pentadecenyl)-1,3-benzenediol, 5-(8,11-pentadecadienyl)-1,3-benzenediol, 5-pentadecene A mixture of alkyl-1,3-benzenediols (about 0.5 moles), 16.5 g of 2-methyl-5-(8-pentadecenyl)-1,3-benzenediol, 2-methyl- Mixture of 5-(8,11-pentadecadienyl)-1,3-benzenediol, 2-methyl-5-pentadecadienyl-1,3-benzenediol (about 0.05 moles) Put it into a high-pressure reaction kettle, add 1.54 grams of potassium hydroxide powder, raise the temperature to 110°C for 60 minutes, and take a sample to detect that the moisture in the material is less than 0.1%. Replace nitrogen, after the oxygen content in the kettle is lower than 500ppm, continue to feed 264 grams (about 6 moles) of ethylene oxide, control the reaction temperature at 155-165 ° C, and complete the introduction of ethylene oxide; then feed 261 grams (about 4.5 moles) of propylene oxi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com