Medical instrument shell polishing machine

A technology of medical equipment and grinding machines, which is applied to the parts of grinding machine tools, grinding machines, grinding drives, etc. It can solve the problems of damaged transmission parts and easy damage of transmission parts, so as to achieve good protection and prevent damage caused by excessive meshing force , the effect of increasing the speed of grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

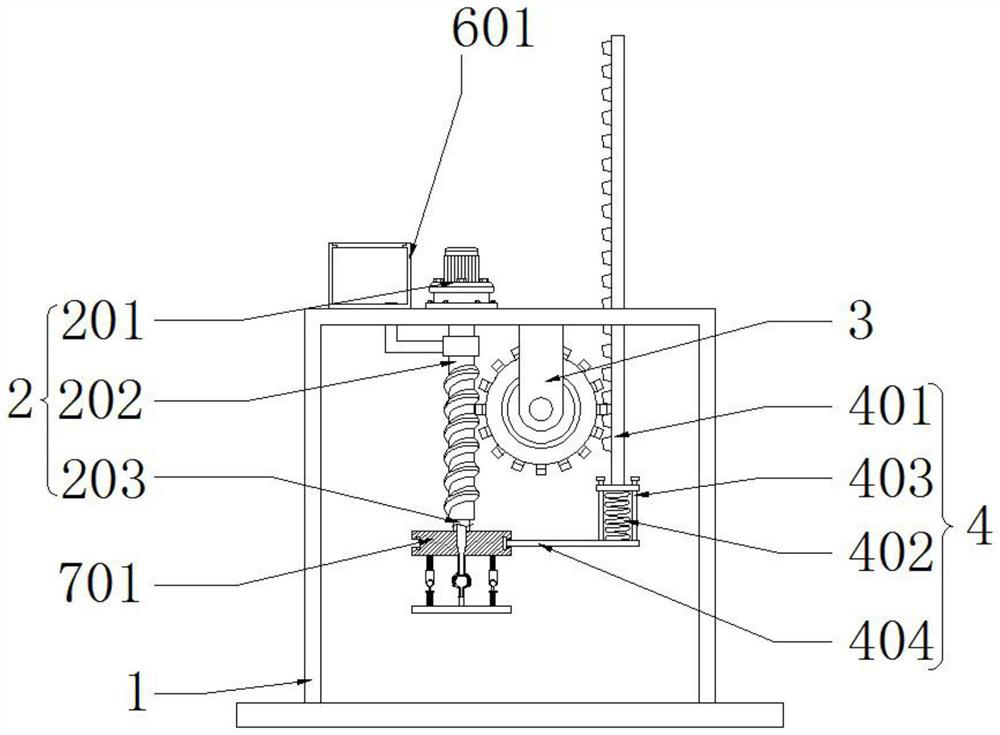

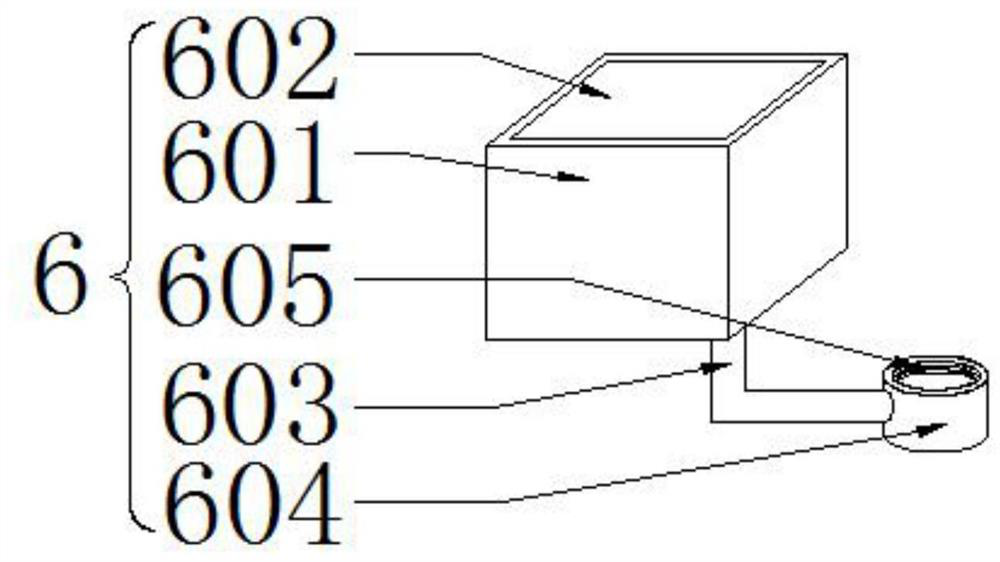

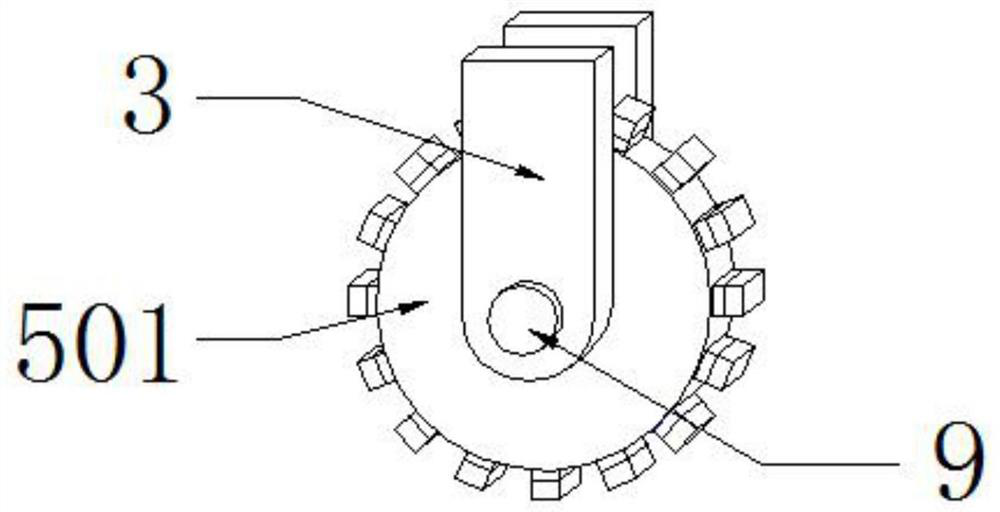

[0028] Such as Figure 1 to Figure 5 As shown, the present invention provides a technical solution: a medical device shell grinding machine, including a device housing 1 and a gear assembly 5, and the upper wall of the equipment housing 1 is provided with a power assembly 2 and a support frame 3 in sequence from left to right And the lifting adjustment assembly 4, and the lower end of the support frame 3 is connected with the gear assembly 5 through the installation pin 9, the external of the power assembly 2 is connected with the auxiliary material assembly 6, and the lower end of the power assembly 2 is connected with the angle rotation assembly 7, the angle rotation assembly 7 Angle auxiliary assembly 8 is arranged around the periphery, and the gear assembly 5 includes a wheel 501, a steel ball 502, a second spring 503 and gear teeth 504, and the middle of the wheel 501 is embedded with a steel ball 502, and the inside of the wheel 501 is provided with a second spring 503, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com