Method and device for eliminating contamination on surface of object

A technology of object surface and gas molecules, which is applied in the field of eliminating contamination on the surface of objects, and can solve problems such as many by-products, surface damage of high-energy electrons, and complex application conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

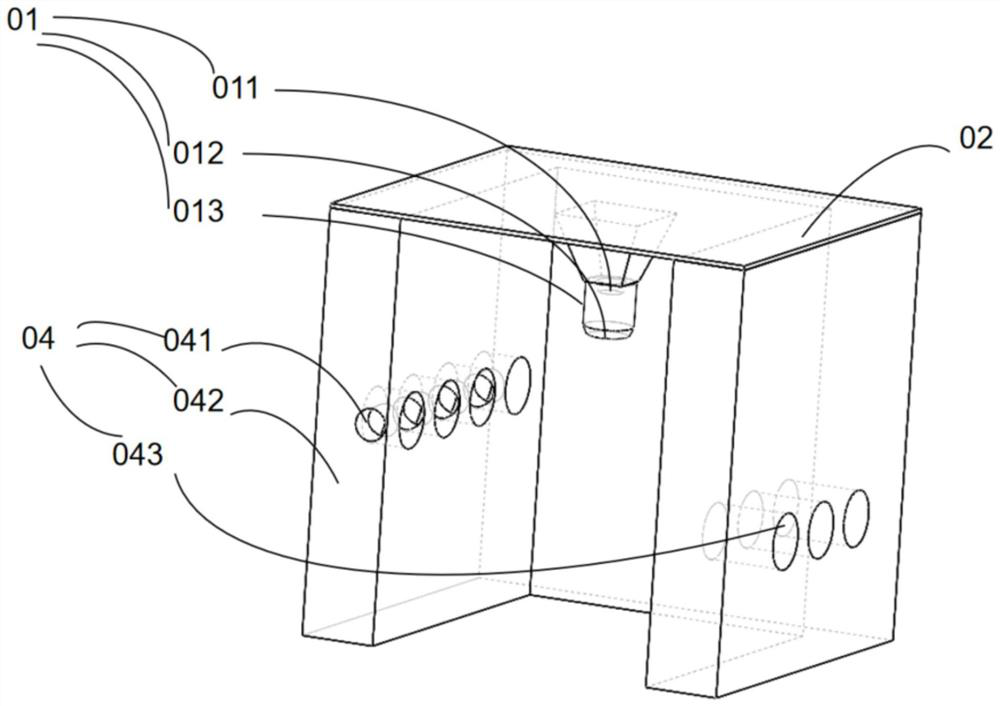

[0075] This embodiment provides a method for eliminating surface contamination. Exemplarily, this method can be used as figure 1 A contaminated surface treatment device is shown, but the present invention is not particularly limited to the structure of the device needed to implement the method. The device includes: a low-energy electron source 01, a control component 02 and a structured atmosphere control component 04;

[0076] The low-energy electron source 01 is installed on the deployment control component 02, and the deployment control component 02 is located above the contaminated surface;

[0077] The low-energy electron source 01 includes a free electron emission structure 011, a multilevel field emission electron window 012 and a vacuum packaging structure 013; there is a gap between the free electron emission structure 011 and the multilevel field emission electron window 012; the vacuum packaging structure 013 is used for Ensure that the gap between the free electr...

Embodiment 2

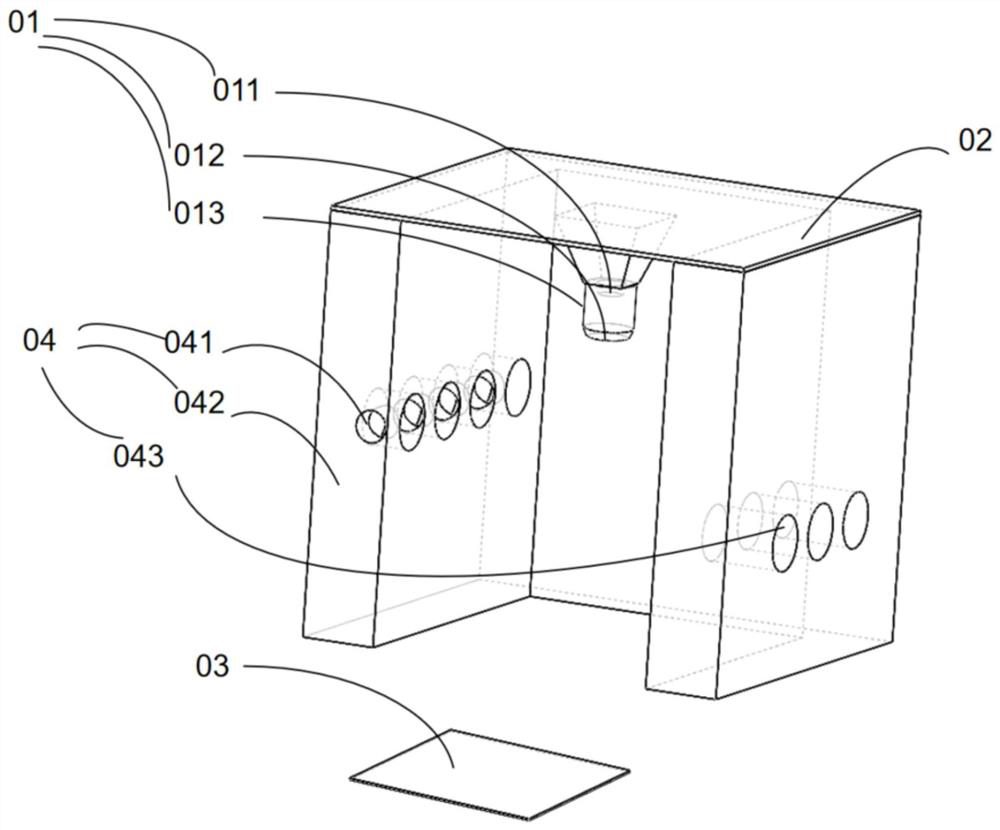

[0088] Such as figure 2 The shown device for eliminating surface contamination includes the following components: a low-energy electron source 01, a control component 02, and an electric field regulation functional structure 03, wherein,

[0089] The low-energy electron source 01 includes a free electron emission structure 011, a multi-level field emission electron window 012, a vacuum packaging structure 013,

[0090] There is a gap of 1 mm between the free electron emission structure 011 and the multi-level field emission electron window 012, which is maintained by a perforated quartz round platform. The vacuum packaging structure 013 is assembled from a dielectric material cavity and a flange plate, with a diameter of about 32 mm, the gap between the free electron emission source 011 and the field emission electron window 012 is achieved and maintained by a mechanical pump and a molecular pump to form a 1×10 -3 Pa low pressure environment,

[0091] The free electron emis...

Embodiment 3

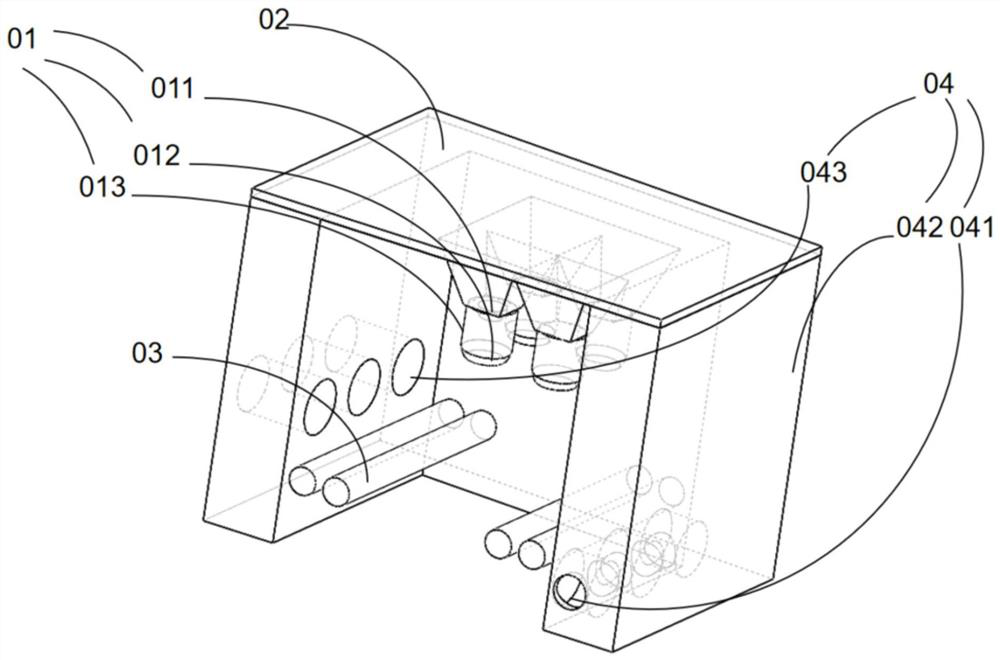

[0100] A device for eliminating surface contamination, including the following components: a low-energy electron source 01, a control component 02, and an electric field regulation functional structure 03, wherein,

[0101] The low-energy electron source 01 includes a free electron emission structure 011, a multi-level field emission electron window 012, a vacuum packaging structure 013,

[0102] There is a gap of about 10 mm between the free electron emission structure 011 and the multi-level field emission electron window 012, which is maintained by a perforated quartz round platform. The vacuum packaging structure 013 is formed by welding a ceramic cavity with a Kovar alloy and a metal packaging plate, with a diameter of About 32 mm, the gap formation between the free electron emission source 011 and the field emission electron window 012 is achieved and maintained by the getter below 1×10 -3 Pa low pressure environment,

[0103] The free electron emission structure 011 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com