Flue gas treatment device for environmental protection engineering

A technology of flue gas treatment and environmental protection engineering, applied in the field of flue gas treatment, can solve the problems of environmental deterioration, low flue gas treatment efficiency, large volume, etc., and achieve the effects of reducing consumption, good self-cleaning function, and high dust removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

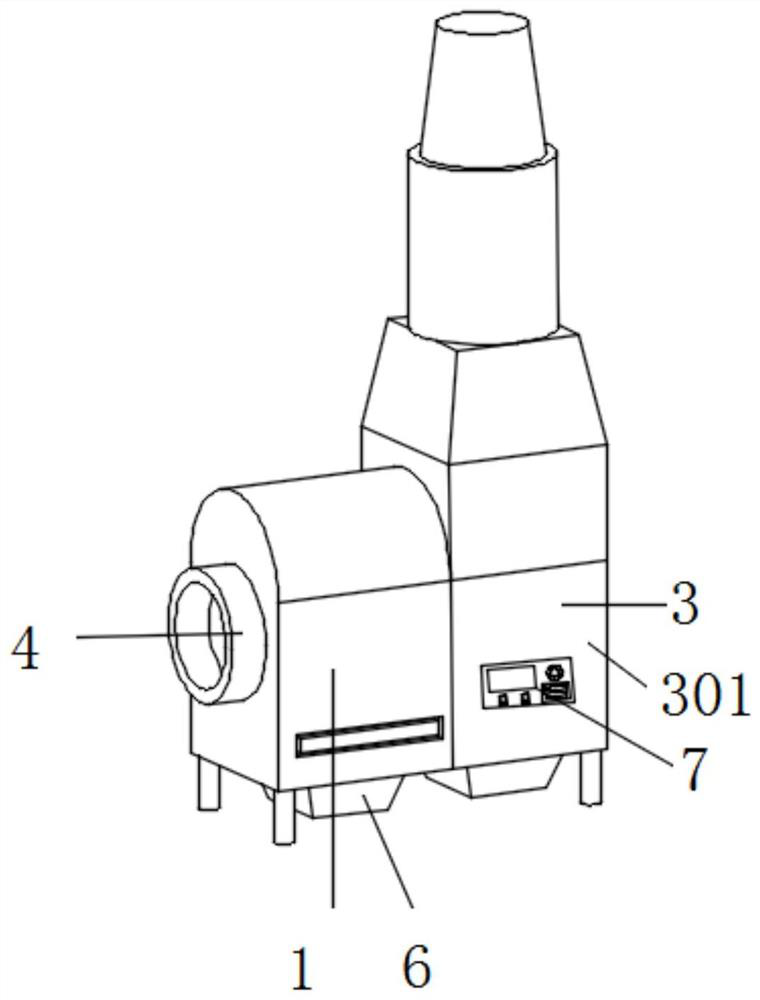

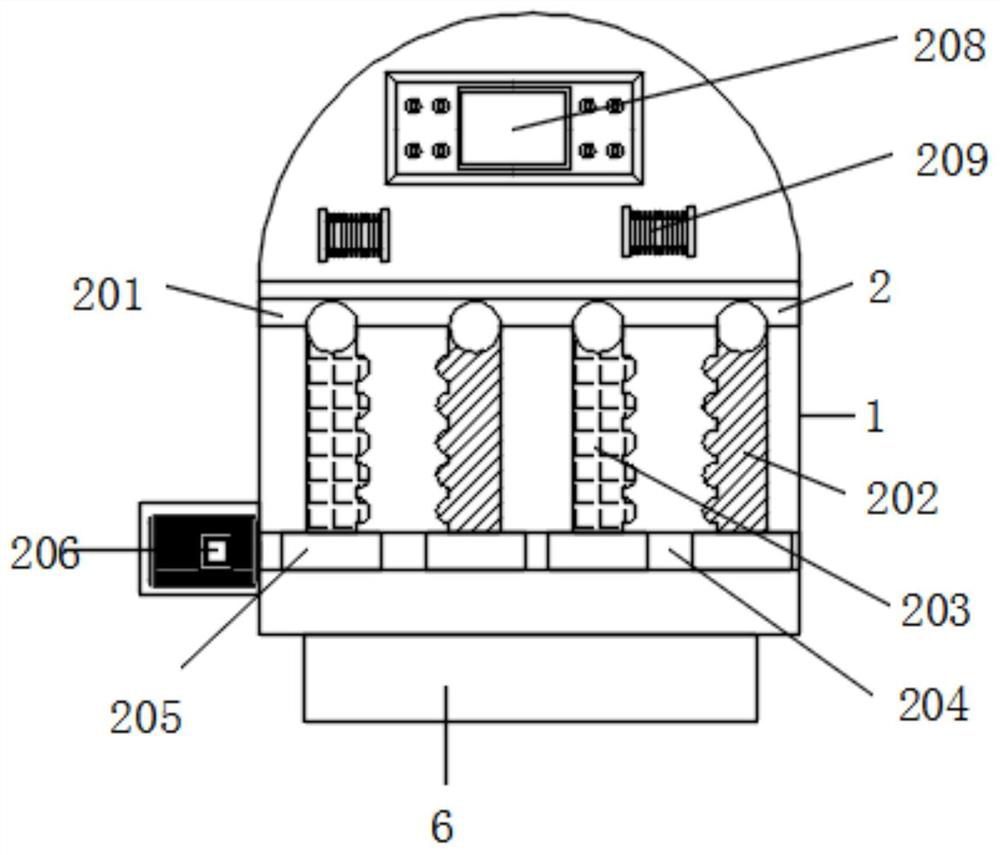

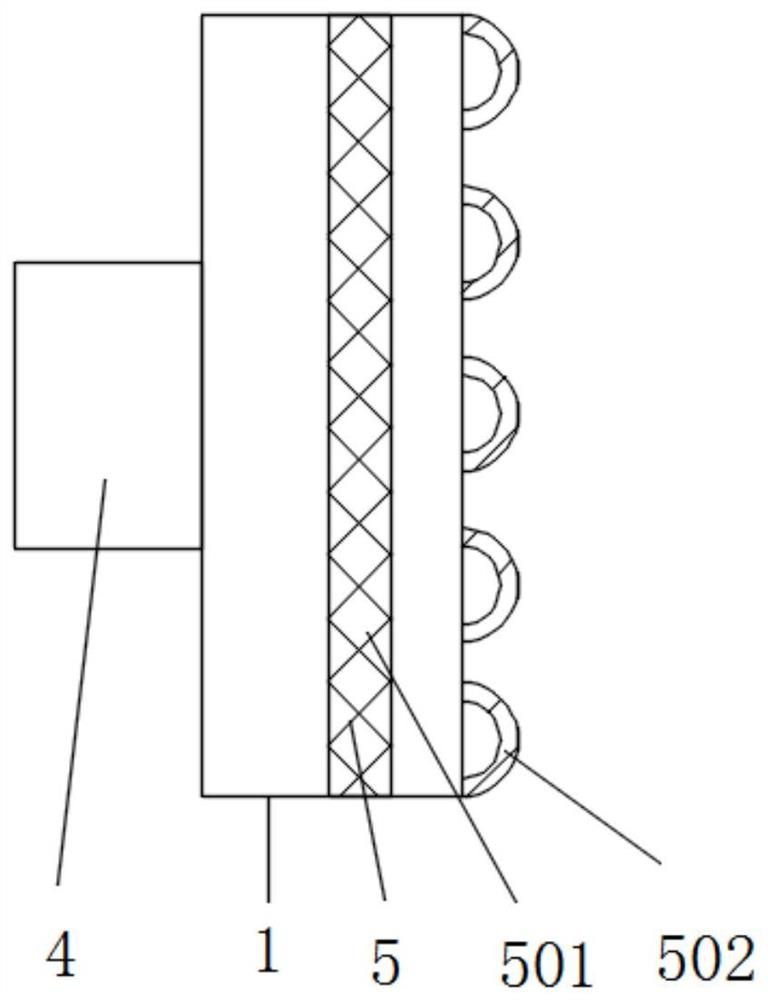

[0028]A flue gas treatment device for environmental protection engineering, comprising a housing 1, a dust removal mechanism 2 and a desulfurization mechanism 3, the dust removal mechanism 2 specifically consists of a cross bar 201, a positive motor 206 plate, a negative motor 206 plate, a rotating rod 204, Block 205, motor 206, eccentric block 207, step-up transformer 208 and rectifier 209. The inner wall of the housing 1 is welded with a cross bar 201, and one side of the cross bar 201 is connected with a positive electrode plate 202 for rotation. One side of the surface of the rod 201 is connected with a negative electrode plate 203 in cooperation with rotation, the surfaces of the positive electrode plate 202 and the negative electrode plate 203 are fixedly connected with a slider 205, and the material of the slider 205 is an insulating material, and the inner wall of the housing 1 cooperates with the rotation A rotating rod 204 is connected, the surface of the rotating rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com