Thick-film resistor paste simultaneously applicable to aluminum oxide ceramic substrate and isolation dielectric layer

A technology of alumina ceramics and isolation medium, which is applied in the direction of conductive materials, circuits, electrical components, etc. dispersed in non-conductive inorganic materials, and can solve the problem of inconvenient use of multilayer thick film integrated circuit products, non-universal products, integrated circuit Problems such as troublesome design and manufacturing process, to achieve the effects of small graphic effect, good resistance consistency, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

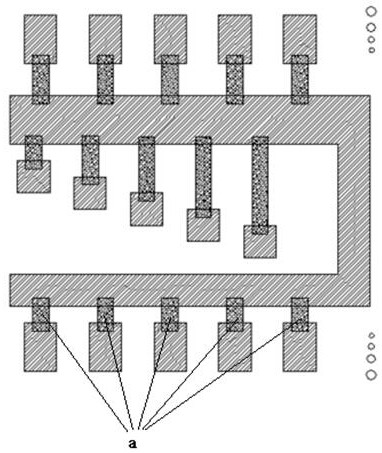

Image

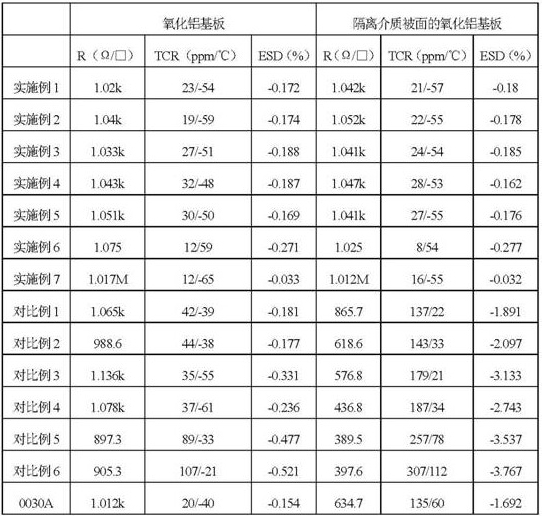

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments, which do not limit the protection scope of the present invention. The protection scope of the present invention is only limited by the claims, and any omission, replacement or modification made by those skilled in the art on the basis of the disclosed embodiments of the present invention will fall within the protection scope of the present invention.

[0016] 1. Selection of conductive powder: the particle size of silver powder ranges from 1 to 3 μm, and the specific surface area of palladium powder is 5 to 15 m 2 / g, the specific surface area of ruthenium dioxide is 25~55m 2 / g, the specific surface area of lead ruthenate is 3~10m 2 / g.

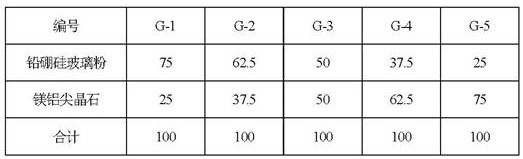

[0017] 2. Preparation of lead borosilicate glass powder: according to the weight percentage of PbO 57%, SiO 2 7%, CaO 13%, Al 2 o 3 3%, B 2 o 3 15% and ZnO 5%. After mixing various oxides evenly, the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com