High-performance PE film as well as preparation method and application thereof

A high-performance, thin-film technology, applied in the field of plastic films, can solve the problems of low printing efficiency, heat resistance, and poor aging resistance, and achieve fast drying speed, smoothness, and long-term stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

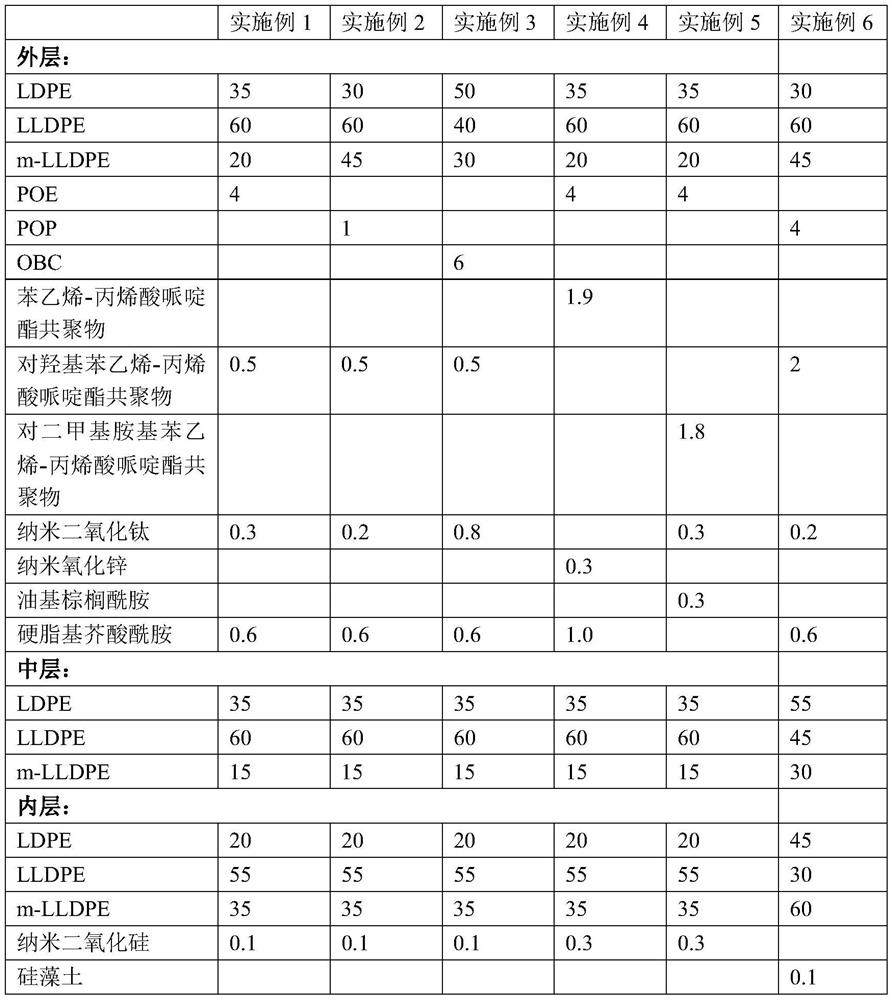

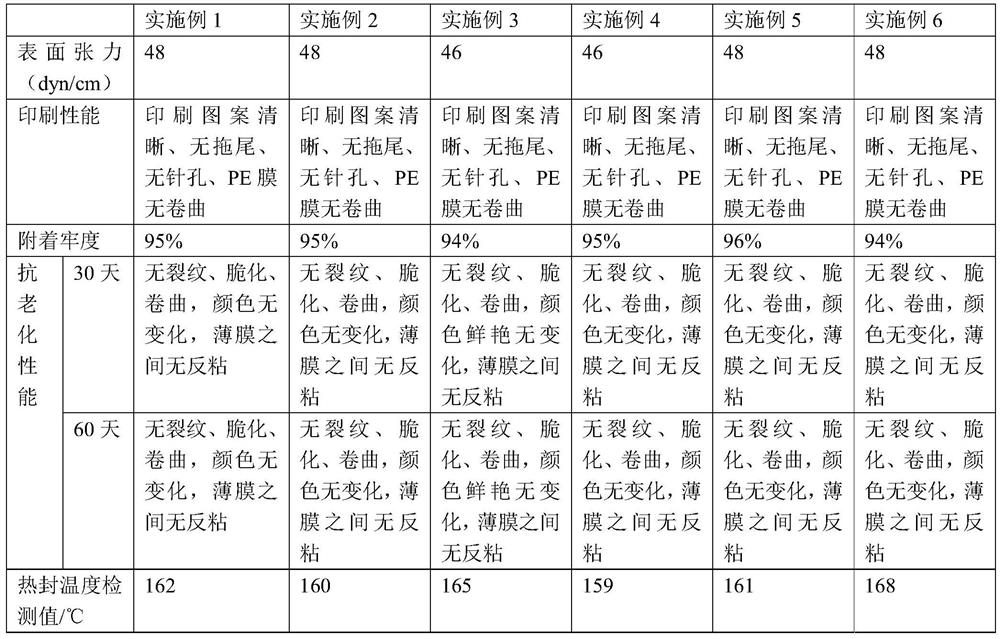

[0062] Embodiments 1-6 provide a PE film whose raw material composition is shown in Table 1.

[0063] Table 1 Outer layer, middle layer and inner layer raw material composition (parts by weight) of PE film

[0064]

[0065] The preparation method of the PE film of embodiment 1~6 is:

[0066] S1. Mix the raw materials of the outer layer, middle layer, and inner layer of the PE film according to the ratio, add them to the extruder respectively, and extrude and granulate to obtain outer layer pellets, middle layer pellets, and inner layer pellets;

[0067] S2. Add the outer layer pellets, middle layer pellets, and inner layer pellets to a three-layer co-extrusion blown film machine respectively, melt and extrude through a three-layer co-extrusion process, and undergo inflation traction, cooling, and corona treatment , film winding to prepare the high-performance PE film;

[0068] Among them, the conditions of corona treatment are: input voltage 220V, output voltage 6kV, vehi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com