Ease-off type blanking bracket for thermal insulation board cutting device

A cutting device and a technology for thermal insulation boards, which are applied in the field of supports, can solve problems such as cracking, bumping on the surface of thermal insulation boards, and impact on the quality of thermal insulation boards, and achieve the effects of reducing cracking, reducing strength and achieving good quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

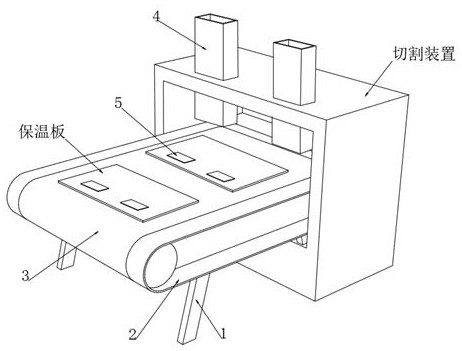

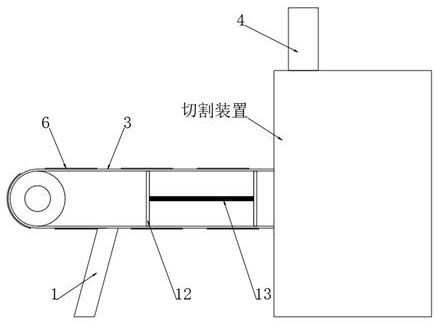

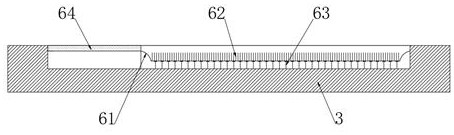

[0040] see figure 1 , a slow-off type blanking bracket for an insulation board cutting device, including a main control board and a conveyor belt 3 at the discharge port of the cutting device, two circular positioning rings 2 installed on both sides of the conveyor belt 3 and fixedly connected to two Two pairs of support rods 1 at the lower end of the circular positioning ring 2, one pair of support rods 1 are connected to the end of the circular positioning ring 2 outside the cutting device, and the other pair of support rods 1 are connected to the inner bottom end of the cutting device's feeding port and the circular positioning Between the rings 2, two magnetic isolation plates 12 are fixedly connected between the upper and lower inner walls of the two circular positioning rings 2, and an electromagnet 13 is electrically connected between the two magnetic isolation plates 12, and the automatic door and the electromagnet 13 are connected with the main The signal connection o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com