Quick connection construction method for large coupling

A construction method and quick connection technology, applied in the direction of instruments, manufacturing tools, metal processing, etc., can solve the problems of high labor intensity, high physical strength, and bolts cannot be fitted smoothly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

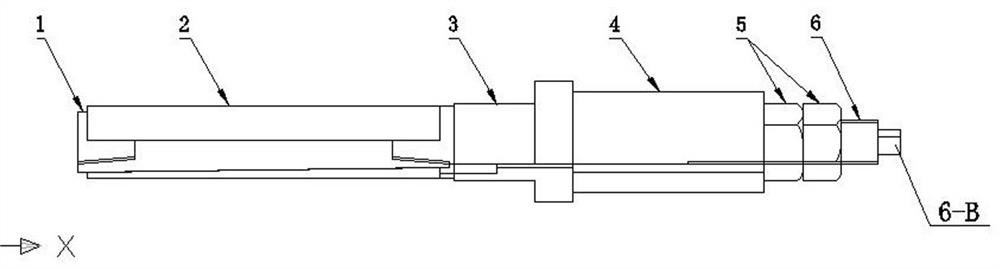

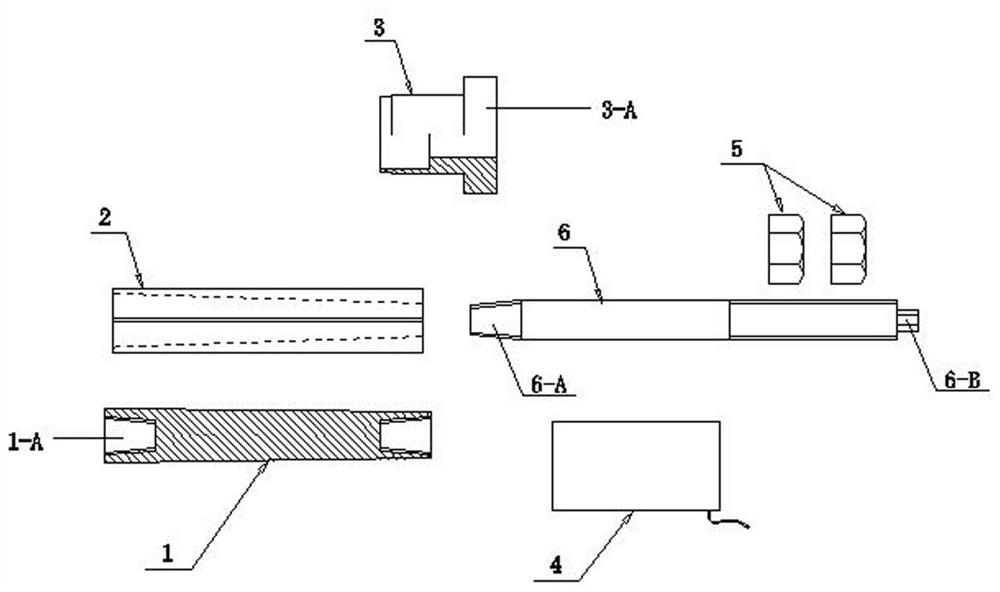

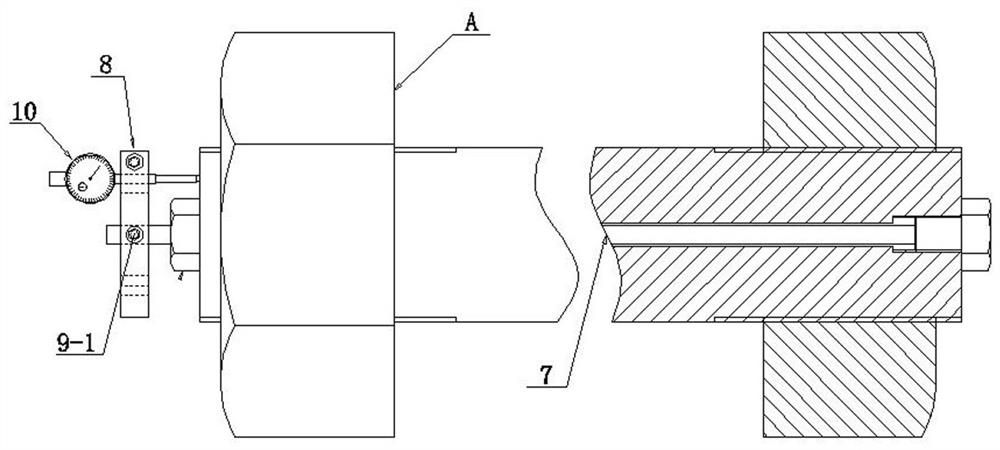

[0033] Example: see Figure 1-Figure 2 , a large-scale coupling quick connection construction method, comprising the following steps:

[0034] A. Construction preparation:

[0035] ①. Place the couplings to be connected on the working platform uniformly, and clean the bolt holes on each coupling so that the end faces of the couplings are smooth and flat without burrs, and the bolt holes on the couplings are internal cleaning;

[0036] ②. Close the couplings to be connected together, fasten them symmetrically with two temporary bolts, and check with a knife edge. The bolt holes can be staggered within 2mm;

[0037] ③. Apply lubricating oil to the outside of the formal coupling bolts, and apply anti-seizure agent or molybdenum disulfide to the threaded fasteners;

[0038] B. Alignment of bolt holes:

[0039] ①. The temporary bolts are not taken out. Insert the cotter pin sleeve 2 into other bolt holes of the coupling, then insert the expansion pin 1 into the cotter pin sleev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com