A multi-die stamping machine for hardware products

A multi-die and punching machine technology, applied in the field of punching equipment, can solve the problems of low angle iron efficiency, poor cutting quality, and reduced processing efficiency of metal steel parts, and achieve the effect of ensuring orderliness and improving processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

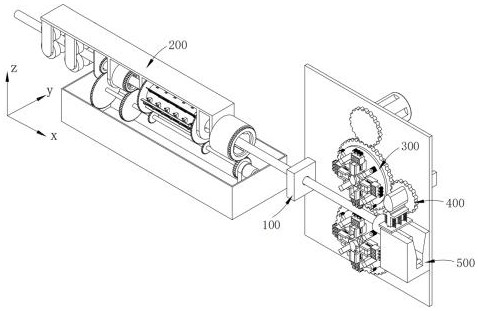

[0039] Such as figure 1 As shown, a multi-die stamping machine for hardware products, including:

[0040] Cold drawn parts 100;

[0041] A lubricating and guiding part 200, the lubricating and guiding part 200 is arranged on one side of the cold drawn part 100;

[0042] A cold drawn part 300, the cold drawn part 300 is arranged on the other side of the cold drawn part 100;

[0043] Stamping part 400, said stamping part 400 is arranged at the conveying end of said cold drawing part 300 to steel rod; And

[0044] an output part 500, the output part 500 is arranged below the stamping part 400;

[0045] The steel rods that are evenly lubricated by the lubricating and conveying part 200 to the rust surface and rust pits are guided to the cold drawn part 100 for cold drawing, and the cold drawing part 300 intermittently applies continuous increasing pressure to the steel parts drawn out of the cold drawn part 100. Subtracting the changing pushing force, the steel piece is pushed t...

Embodiment 2

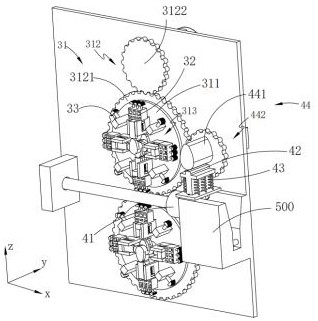

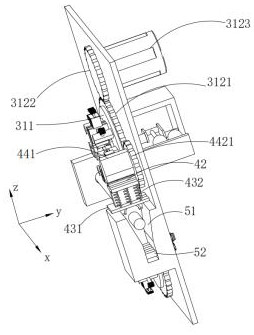

[0089] Such as figure 2 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between the second embodiment and the first embodiment is that the stamping part 400 includes:

[0090] Positioning cylinder 41;

[0091] A stamping part 42, the stamping part 42 is arranged on one side of the positioning cylinder 41;

[0092] a holding part 43 on which the stamping part 42 is mounted; and

[0093] The stamping driving part 44 , the power end of the stamping driving part 44 is connected with the stamping part 42 .

[0094] In this embodiment, the stamping part 400 stamps and cuts off the steel rod delivered by the cold drawing part 300 when the push piece 32 leaves the steel rod, and the stamping part 42 on the holding part 43 is driven by the stamp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com