Resin composition and application thereof

A technology of resin composition and epoxy resin, which is applied in the field of laminates, can solve the problems of improving film elongation, peel strength, and low CTE, and achieve the effects of avoiding reliability influence, good elongation, and small average particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

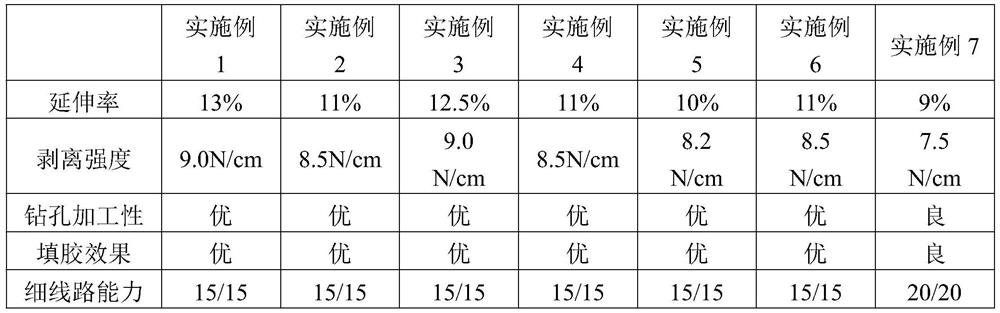

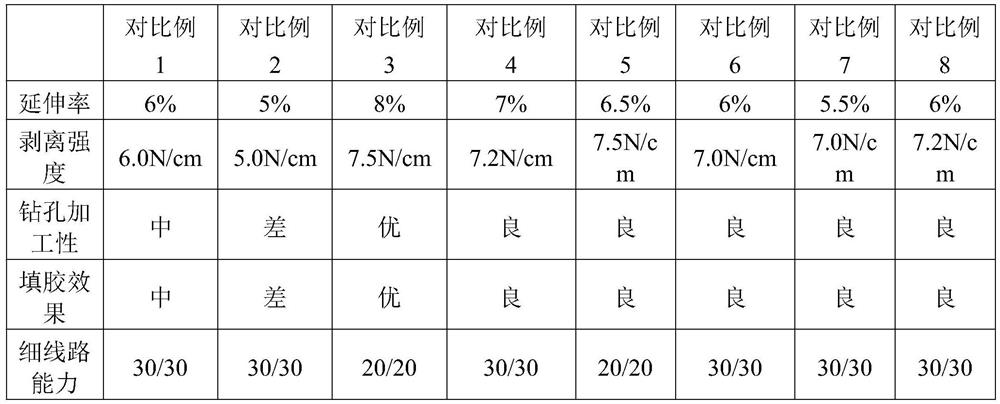

Examples

Embodiment 1

[0056] First dissolve 40 parts of epoxy resin (NC-3000H) and 30 parts of phenolic resin (SN-485) with an appropriate amount of solvent, and stir for more than 2 hours.

[0057] Then add 30 parts of silicon dioxide 3 (D50 is 0.5 μm, D100:D10 is 2.0, and the purity is 99.90%) obtained by organosilicon hydrolysis, and continue to stir for more than 4 hours, and mix well to form a solid content of 65%. solution.

[0058] The above solution was coated on the release film, and after drying, it was baked in an oven at 120°C for 3 minutes to obtain an adhesive film of a semi-cured resin layer. Press and cure the semi-cured adhesive film (thickness 40 μm) and the browned PCB board, tear off the release film and then perform surface treatment, copper electroplating, to form a laminated printed circuit board with lines.

Embodiment 2

[0060] Except changing the ratio of silicon dioxide synthesized by the chemical method used in Example 1, the same method as in Example 1 was used to manufacture the adhesive film.

[0061] First dissolve 23 parts of epoxy resin (NC-3000H) and 17 parts of phenolic resin (SN-485) with an appropriate amount of solvent, and stir for more than 2 hours.

[0062] Then add 60 parts of silicon dioxide 3 (D50 is 0.5 μm, D100:D10 is 2.0, and the purity is 99.90%) obtained by organosilicon hydrolysis, and continue to stir for more than 4 hours, and mix well to form a solid content of 65%. solution.

[0063] The above solution was coated on the release film, and after drying, it was baked in an oven at 120°C for 3 minutes to obtain an adhesive film of a semi-cured resin layer. Press and cure the semi-cured adhesive film (thickness 40 μm) and the browned PCB board, tear off the release film and then perform surface treatment, copper electroplating, to form a laminated printed circuit boar...

Embodiment 3

[0065] First dissolve 30 parts of epoxy resin (NC-3000H) and 25 parts of phenolic resin (SN-485) with an appropriate amount of solvent, and stir for more than 2 hours.

[0066] Then add 45 parts of silicon dioxide 2 (D50 is 0.1 μm, D100:D10 is 2.3, and the purity is 99.90%) obtained by organosilicon hydrolysis, and continue to stir for more than 4 hours, and mix well to form a solid content of 65%. solution.

[0067] The above solution was coated on the release film, and after drying, it was baked in an oven at 120°C for 3 minutes to obtain an adhesive film of a semi-cured resin layer. Press and cure the semi-cured adhesive film (thickness 40 μm) and the browned PCB board, tear off the release film and then perform surface treatment, copper electroplating, to form a laminated printed circuit board with lines.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com