A method for removing impurity ions in an ionic liquid aqueous solution system

A technology of ionic liquid and impurity ions, which is applied in separation methods, general water supply conservation, chemical instruments and methods, etc., can solve the problem that impurity ions are rarely reported, and achieve good application prospects, improve effective separation efficiency, and efficient recovery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

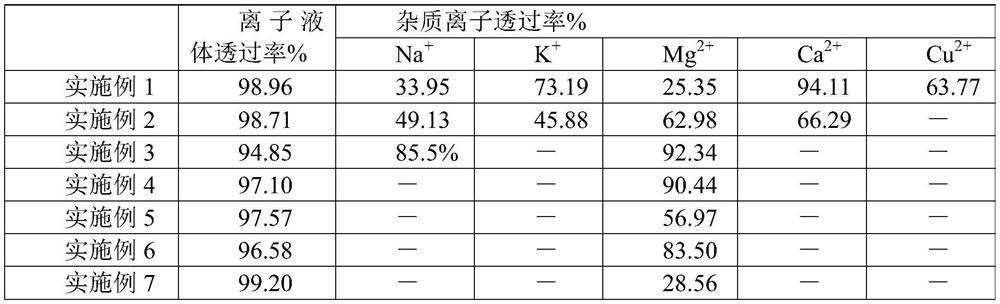

Embodiment 1

[0038] This embodiment provides a method for removing impurity ions in an ionic liquid aqueous solution system. The ionic liquid in the ionic liquid aqueous solution to be purified is alkylimidazolium salt 1-ethyl-3 methylimidazole diethyl phosphate salt, and the impurity ion is potassium Ions, a mixture of sodium ions, calcium ions, magnesium ions, and copper ions, the positive membrane used is a sulfonic acid type cation exchange membrane CIMS, and the negative membrane is a quaternary ammonium type anion exchange membrane AGU;

[0039] Specific steps are as follows:

[0040] (1) 500mL ionic liquid concentration is 20g / L, impurity ion concentration is respectively the ionic liquid aqueous solution to be purified of 0.5g / L and is passed into the desalination chamber of electrodialysis device, with flow rate being 30L / (min·m 2 ) to cycle;

[0041] (2) 500mL of water (that is, the concentration of the ionic liquid is 0g / L) is entered into the concentration chamber of the elect...

Embodiment 2

[0047] This embodiment provides a method for removing impurity ions in an ionic liquid aqueous solution system. The ionic liquid in the sample to be treated is alkylimidazolium salt 1-ethyl-3 methylimidazole diethyl phosphate salt, and the impurity ion is potassium ion. A mixture of sodium ions, calcium ions, and magnesium ions, the cationic membrane used is a sulfonic acid-type cation-exchange membrane CIMS, and the anion-membrane is a quaternary ammonium-type anion-exchange membrane AGU;

[0048] Specific steps are as follows:

[0049] (1) 500mL ionic liquid concentration is 20g / L, impurity ion concentration is respectively the ionic liquid aqueous solution to be purified of 0.5g / L and is passed into the desalination chamber of electrodialysis device, with flow rate being 30L / (min·m 2 ) to cycle;

[0050] (2) 500mL of water (that is, the concentration of the ionic liquid is 0g / L) is entered into the concentration chamber of the electrodialysis device as a concentrated solut...

Embodiment 3

[0056] This embodiment provides a method for removing impurity ions in an ionic liquid system. The ionic liquid in the aqueous ionic liquid solution to be purified is alkylimidazolium salt 1-ethyl-3-methylimidazole diethyl phosphate salt, and the impurity ion is sodium ion , a mixture of magnesium ions, the positive membrane used is a sulfonic acid type cation exchange membrane CIMS, and the negative membrane is a quaternary ammonium type anion exchange membrane AGU;

[0057] Specific steps are as follows:

[0058] (1) 500mL ionic liquid concentration is 20g / L, impurity ion concentration is respectively the ionic liquid aqueous solution to be purified of 0.5g / L and is passed into the desalination chamber of electrodialysis device, with flow rate being 30L / (min·m 2 ) to cycle;

[0059] (2) 500mL of water (that is, the concentration of the ionic liquid is 0g / L) is entered into the concentration chamber of the electrodialysis device as a concentrated solution at a flow rate of 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com