Worm machining process

A processing technology and worm technology, applied in the field of worm processing technology, can solve the problems of low transmission power, worm collision, cumbersome and other problems, and achieve the effect of convenient handling and collision prevention.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0044] Please refer to Figure 1-Figure 10 , in the first embodiment of the present invention, the worm machining process includes the following steps:

[0045] S1: forging the blank;

[0046] S2: Carry out heat treatment after rough turning of the outer circle of the blank;

[0047] S3: After grinding the center hole, turn the fastening thread;

[0048] S4: semi-fine grinding outer circle and spiral cotton;

[0049] S5: repeated grinding of the center hole;

[0050] S6: Finally, perform fine grinding on the outer ring, end face and helical face in sequence.

[0051] In the above S1-S6, the worm modular mobile frame is used to carry out the worm transfer work during the worm machining process.

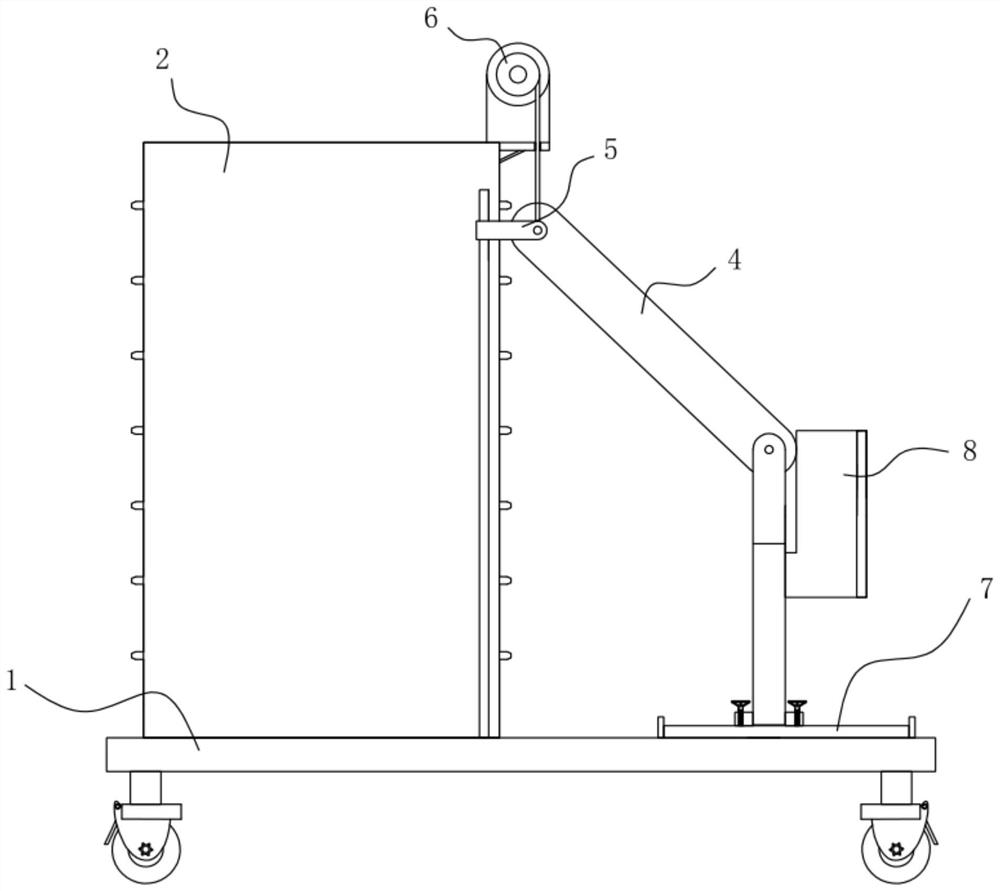

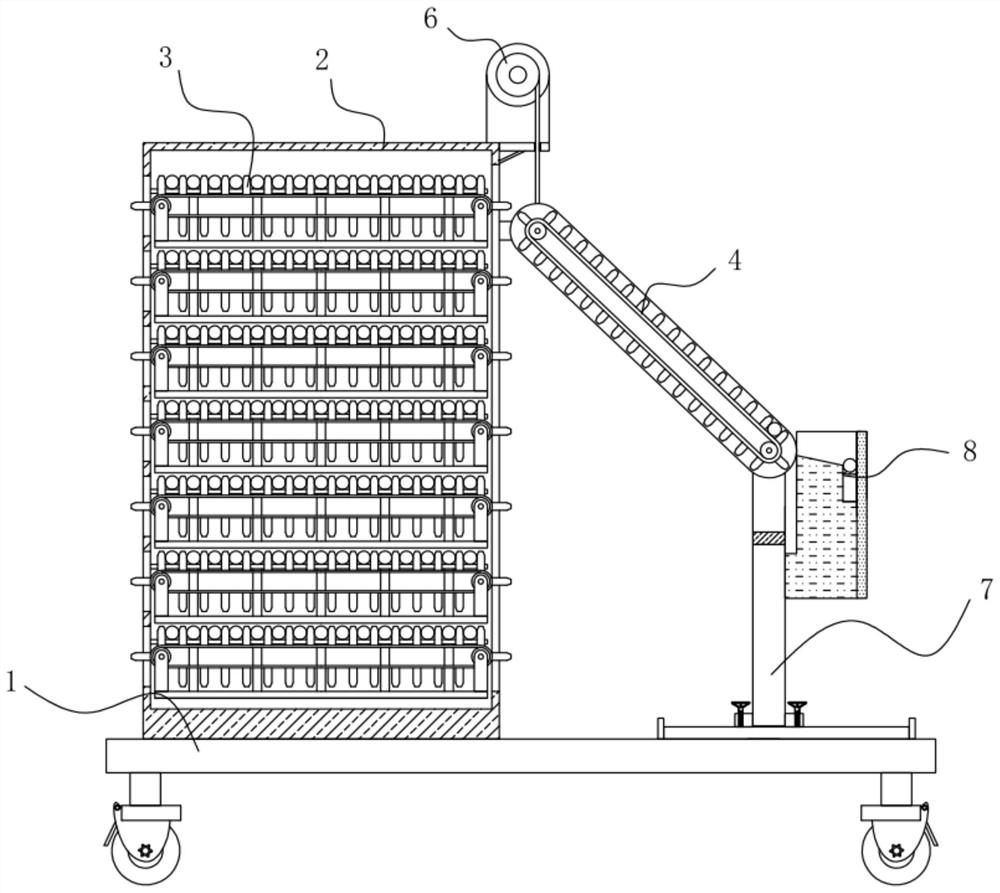

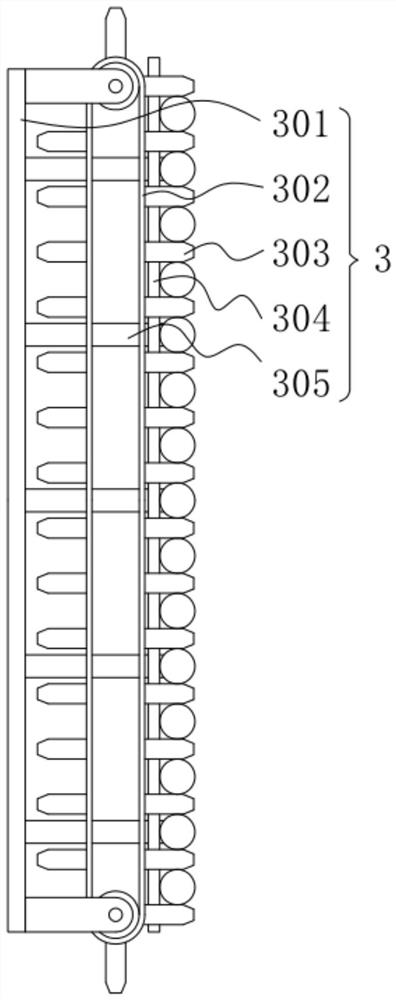

[0052] Such as figure 2 As shown, the worm modular mobile frame provided in this embodiment includes a base plate 1, four universal wheels distributed in a rectangular shape are fixedly installed on the bottom of the base plate 1, and a storage box 2 is fixedly installed on the ...

no. 2 example

[0064] Based on the worm modular mobile frame provided in the first embodiment of the present application, the second embodiment of the present application proposes another worm modular mobile frame. The second embodiment is only a preferred mode of the first embodiment, and the implementation of the second embodiment will not affect the independent implementation of the first embodiment.

[0065] The second embodiment of the present invention will be further described below in conjunction with the drawings and implementation methods.

[0066] Please refer to the figure Figure 11-Figure 14 , in this embodiment, the first connecting block 801 is slidably connected to the bar-shaped supporting block 701, and the first connecting block 801 and the bar-shaped supporting block 701 are set to be slidably connected, and then matched with the second connecting block 801 at the bottom of the first connecting block 801 A hydraulic cylinder 10 can realize the overall independent liftin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com